New Componit is an Italian company with 25 years’ experience in high-temperature solutions. We design, produce and install expansion joints, insulating blankets and safety shields.

We use solutions based on fabric, coated fabric, rubber, plastic and elastomers.

Expansion joints and insulation pillows are key components in power production and industrial processes. Each solution is customised around customer’s needs, developed with the support of the best suppliers, the latest technology and highest quality materials.

New Componit mainly serves the energy market. We provide solutions for:

- Power plants

- Gas and steam turbine systems

- Heaters

- Exhaust ducts

- Waste to energy incineration furnaces

- Chemical and petrochemical plans

- Food production

- Steel, cement, ceramic and glass production

- Ship and cruise vessels

- Biomasses plant and genset

- Pulp and paper production

- Bulk material handling

Fabric expansion joints

We offer a wide variety of solutions with the following application families:

- CHEMFLEX: Minimum propagation of vibrations in temperatures up to 280°C. Used in ventilation ducts and blowers

- VIBRAFLEX: Maximum resistance to chemical aggressive agents in temperatures up to 280°C. Used in chimney boiler connections

- ENERFLEX: Maximum application versatility in temperatures up to 650°C. Used in air ducts

- POWERFLEX: Maximum chemical resistance to combustion fume components in temperatures up to 650°C. Used in exhaust ducts

- NAVIFLEX: Maximum noise reduction and maximum pressure tightness in temperatures up to 650°C. Used in ship gas turbines

- PIPERFLEX: Maximum movement and heat reduction in temperatures up to 900°C. Used in HRSG

- TURBOFLEX: Maximum resistance to pulsation and erosive agents connected to fumes turbulence and high speed. Temperatures up 1,000°C. Used in gas turbine exhaust ducts

- PETROFLEX : Maximum resistance to high temperatures up to 1,400°C. Used in incineration furnaces and catalytic cracking

Rubber joints

We produce rubber joints used for air inlets, fans, ventilation, DeNox, DeSox and noise and vibration reduction. Our products work within temperatures up to 250°C. We fabricate these rubber joints using:

- EPDM

- Hypalon

- Neoprene

- Viton

Thermoproof insulation blankets

We provide a range of solutions dedicated to industrial heat insulation and soundproofing. Our flexible blankets are easy to remove and re-install, as requested by frequent maintenance job in power plants. We collect body measurements on-site, then design, produce and install using our specialist support.

We provide solutions for the following applications:

- Gas and steam turbines

- Exhaust diffusers

- Duct and pipes

- Valves and compressors

- Diesel engines

- Exhaust systems

- Power plants

- Industrial plants

Safety shields

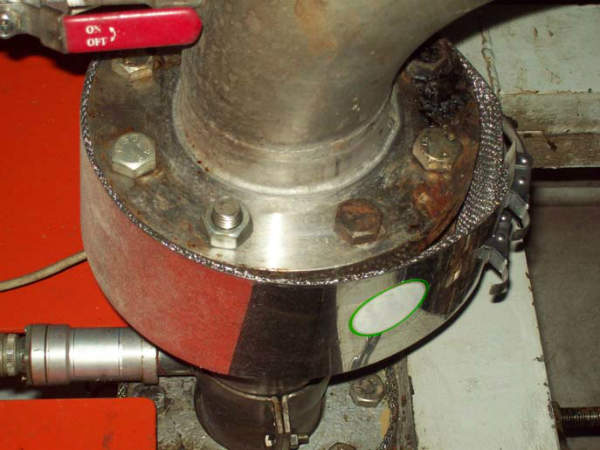

Safety in the industrial workplace is a top priority and a worldwide issue. We developed the Chemshield family of products to protect people and equipment from dangerous liquid and pressure sprayouts.

Chemshield are flexible jackets, adjusted around valves and flange connections, stopping the leakage and deviating it to the ground. We are RINA certified.

Material used include:

- Glass, polyester, nomex, kevlar fabric

- PTFE coated fabric

- Silicone or viton coated fabric

- Stainless steel

- PVC and PPL

Service activities

We provide on-site services all around the world. Every product’s performance and lifespan depends on state-of-the-art installation and maintenance.

New Componit has a professional team, capable of executing the following on-site activities:

- Installation and maintenance

- Supervision activities

- Monitoring and analysis