Welcome to the leading provider of cutting-edge remote-handling solutions for the nuclear industry. Explore our range of innovative products and services, including advanced telemanipulators and robotics, precision engineering, and custom solutions tailored to the demanding needs of the nuclear industry. Discover how we elevate safety and productivity while ensuring exceptional quality and reliability.

Leadership in Nuclear Industry Teleoperation: Unveiling Cutting-Edge Solutions

Wälischmiller Engineering stands as a pioneer in delivering advanced robotics and remote-handling systems designed to nuclear operations. With a steadfast commitment to excellence, we present solutions that amplify efficiency, accuracy, and safety within the unique demands of nuclear applications.

Nuclear-Focused Remote Handling Excellence

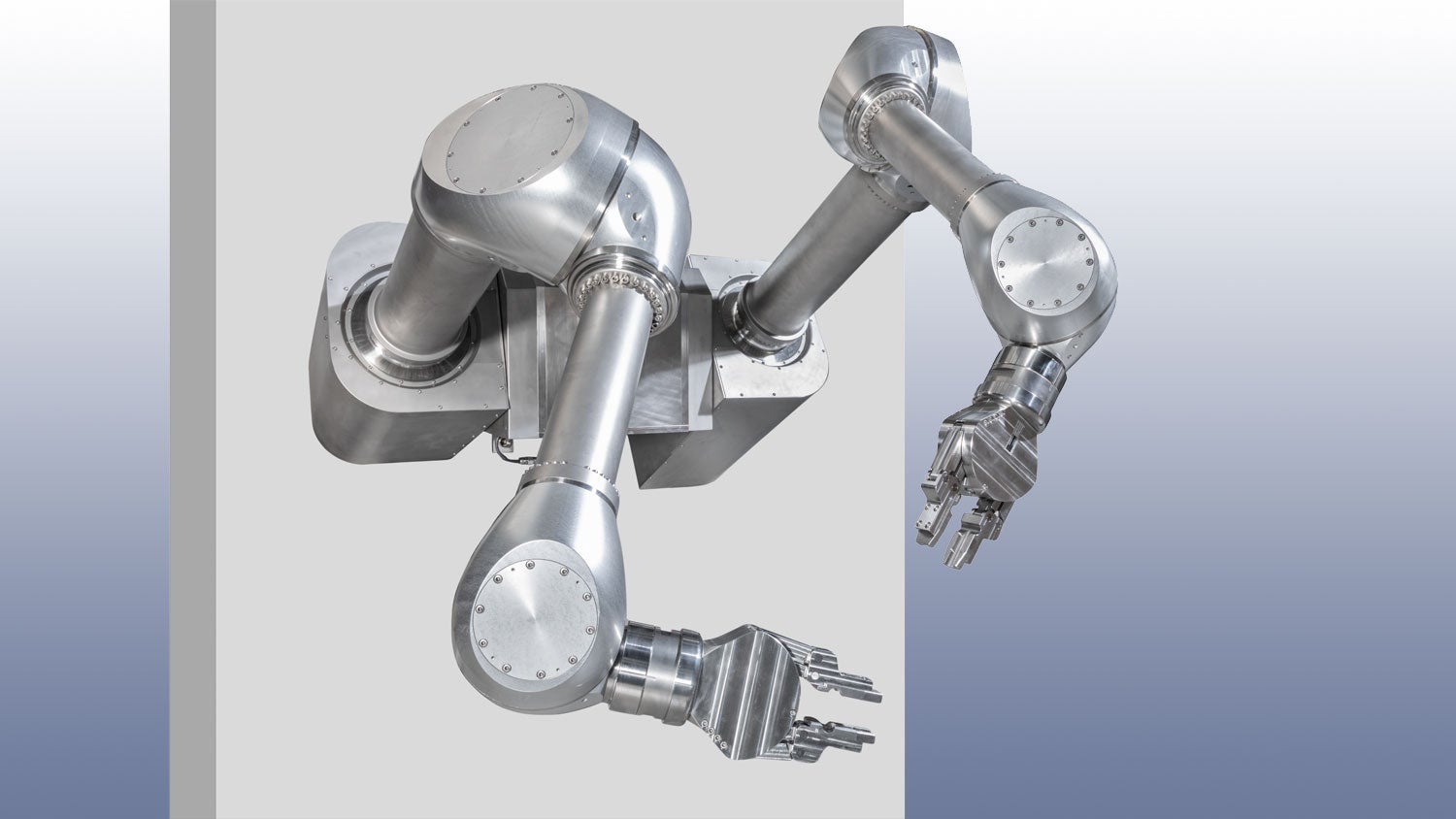

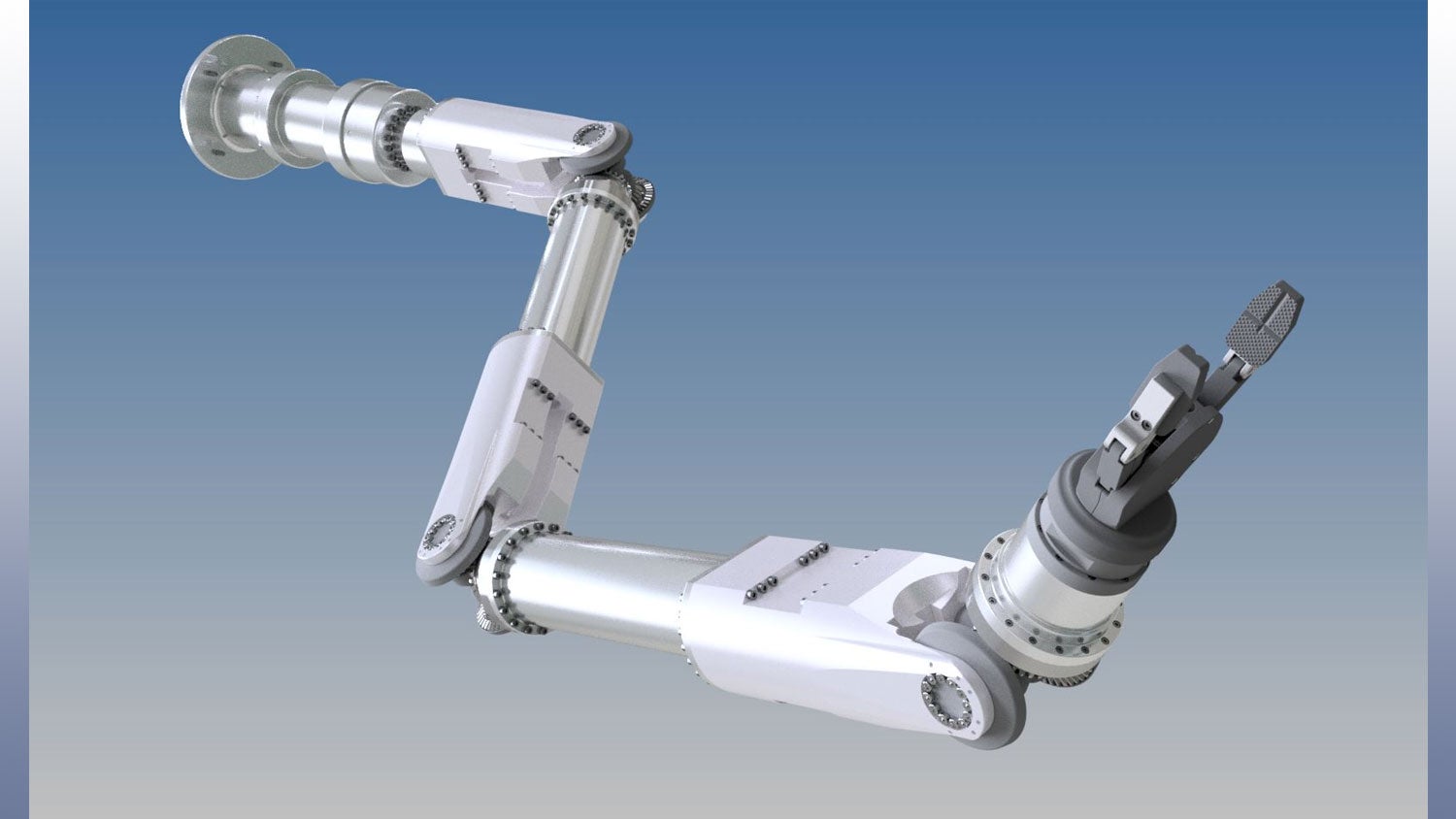

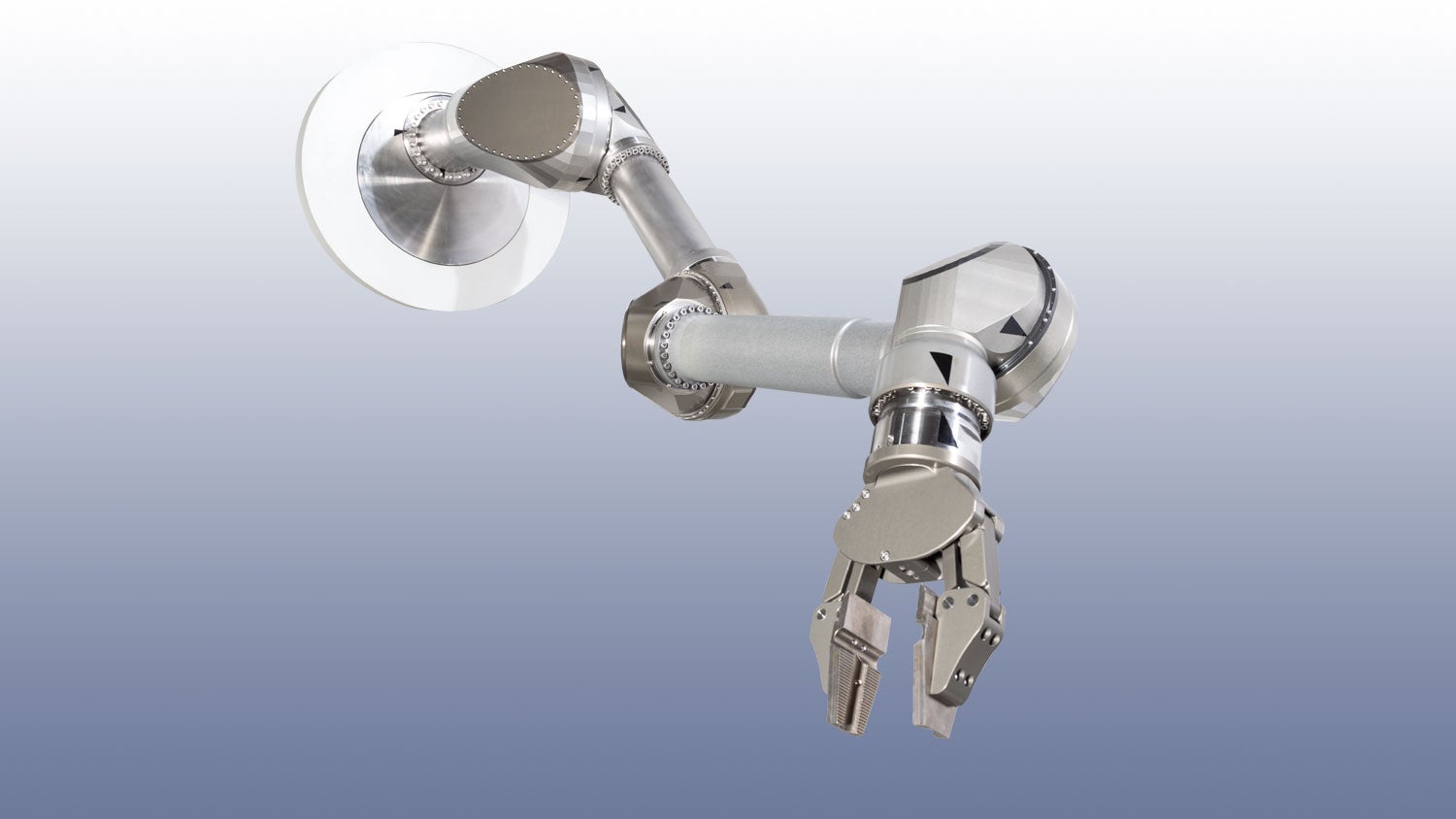

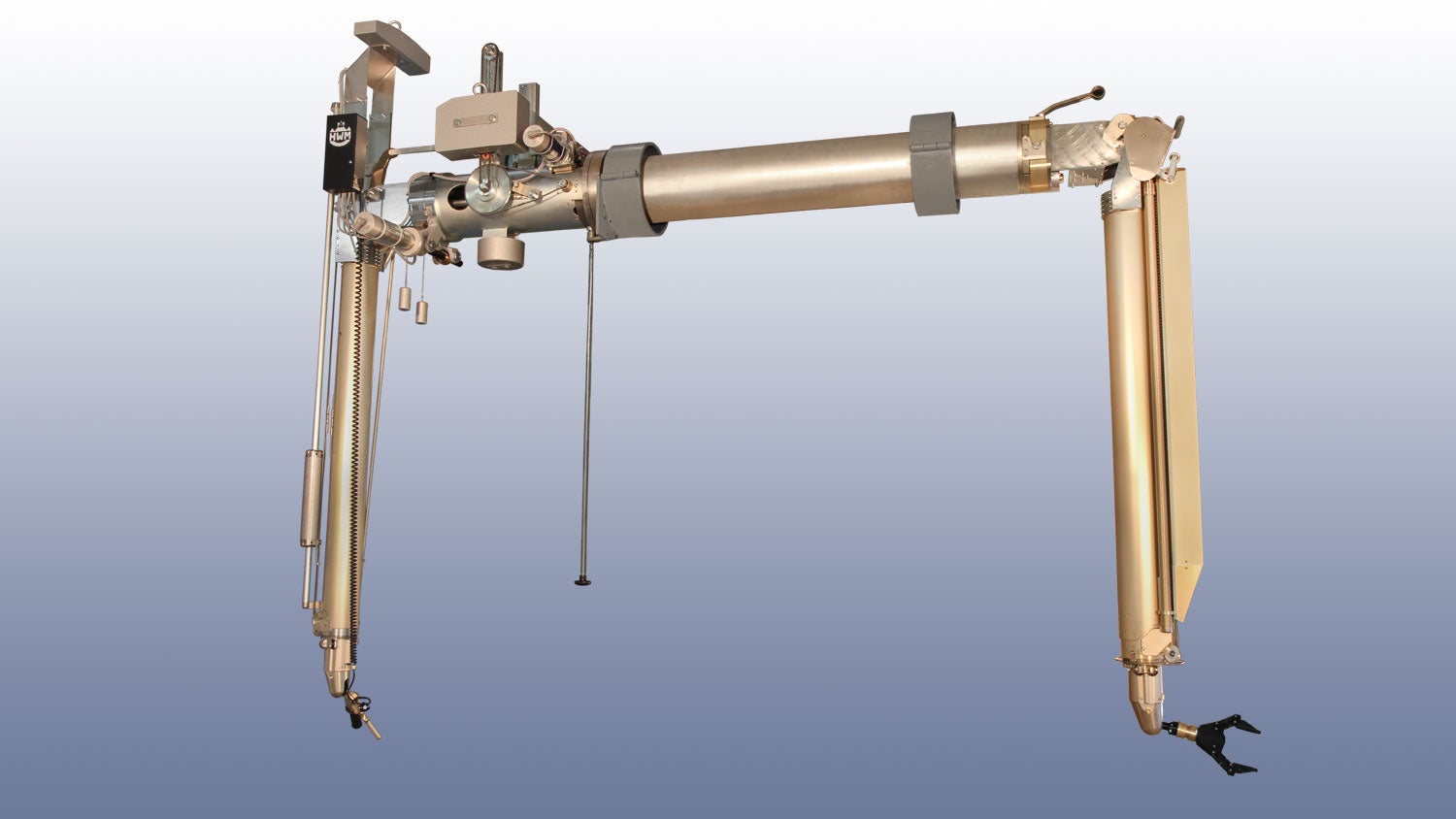

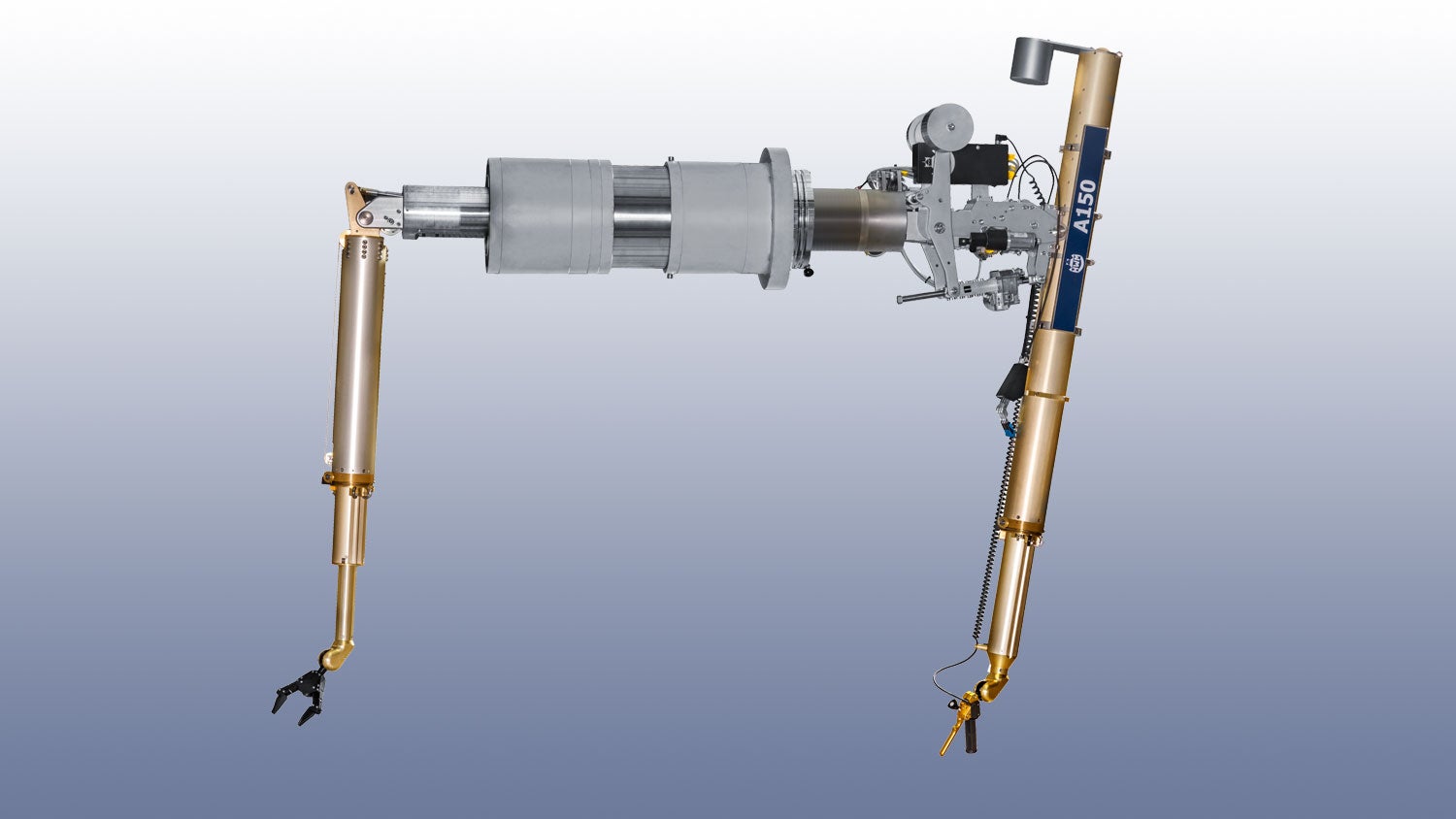

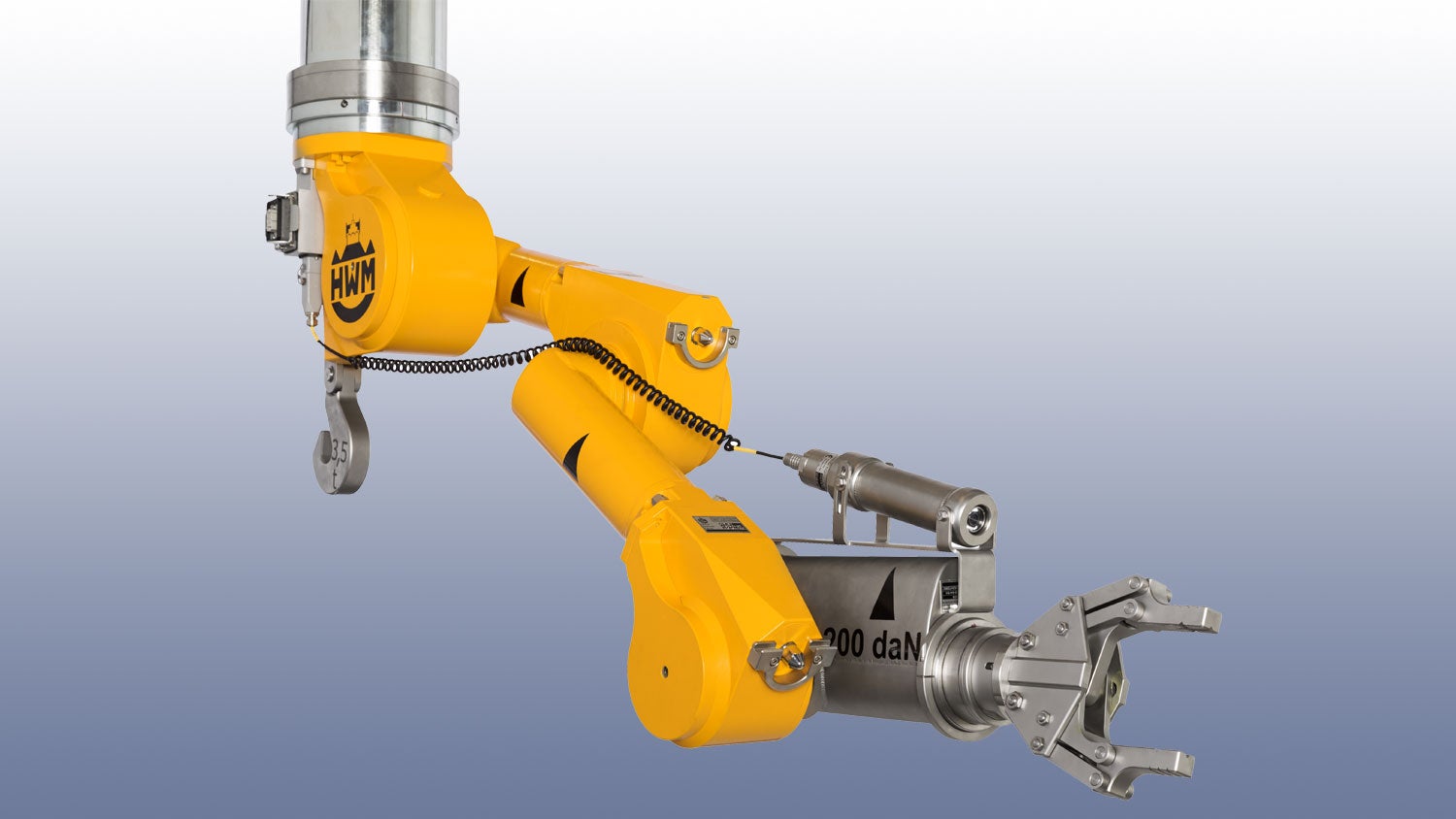

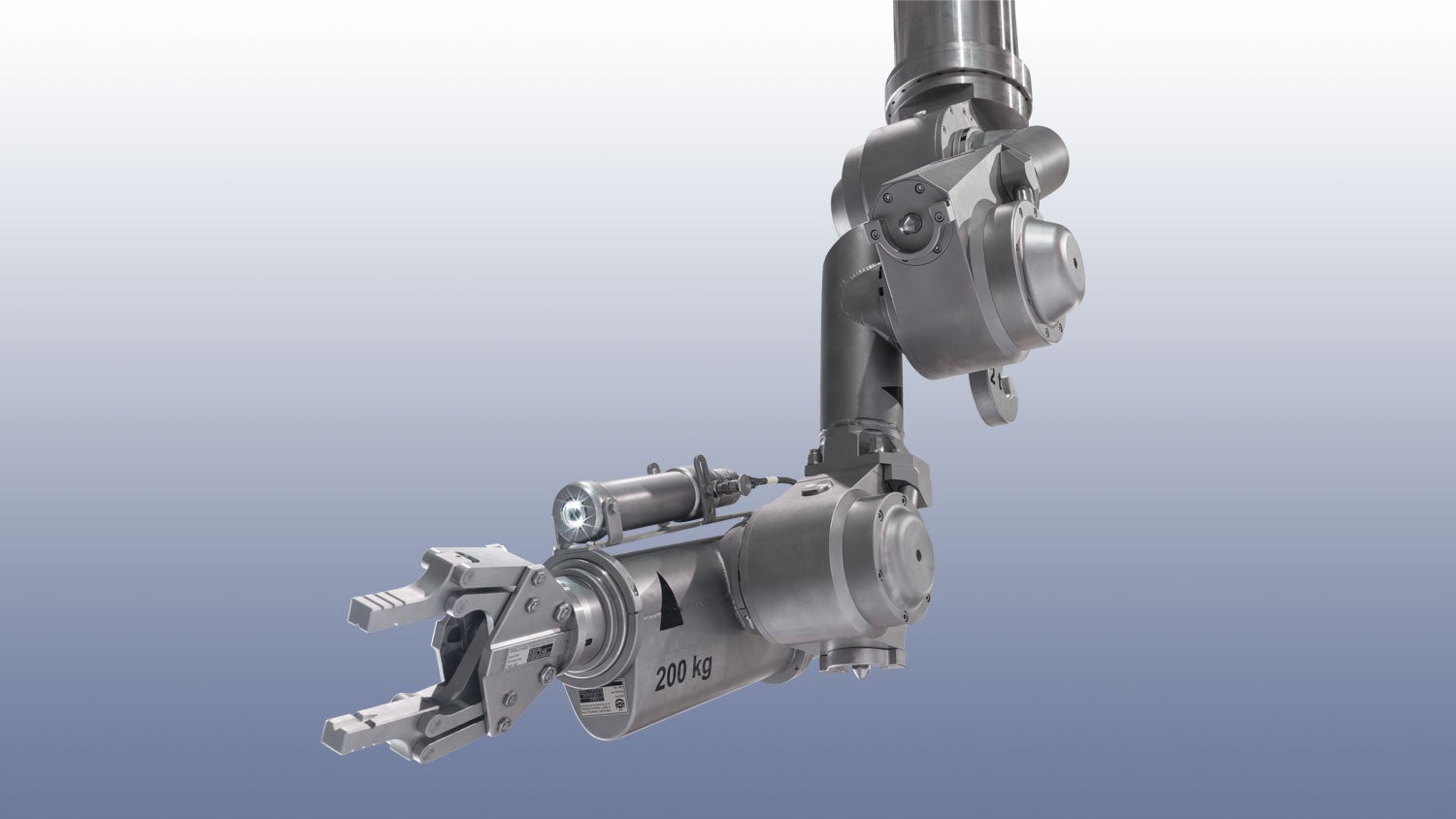

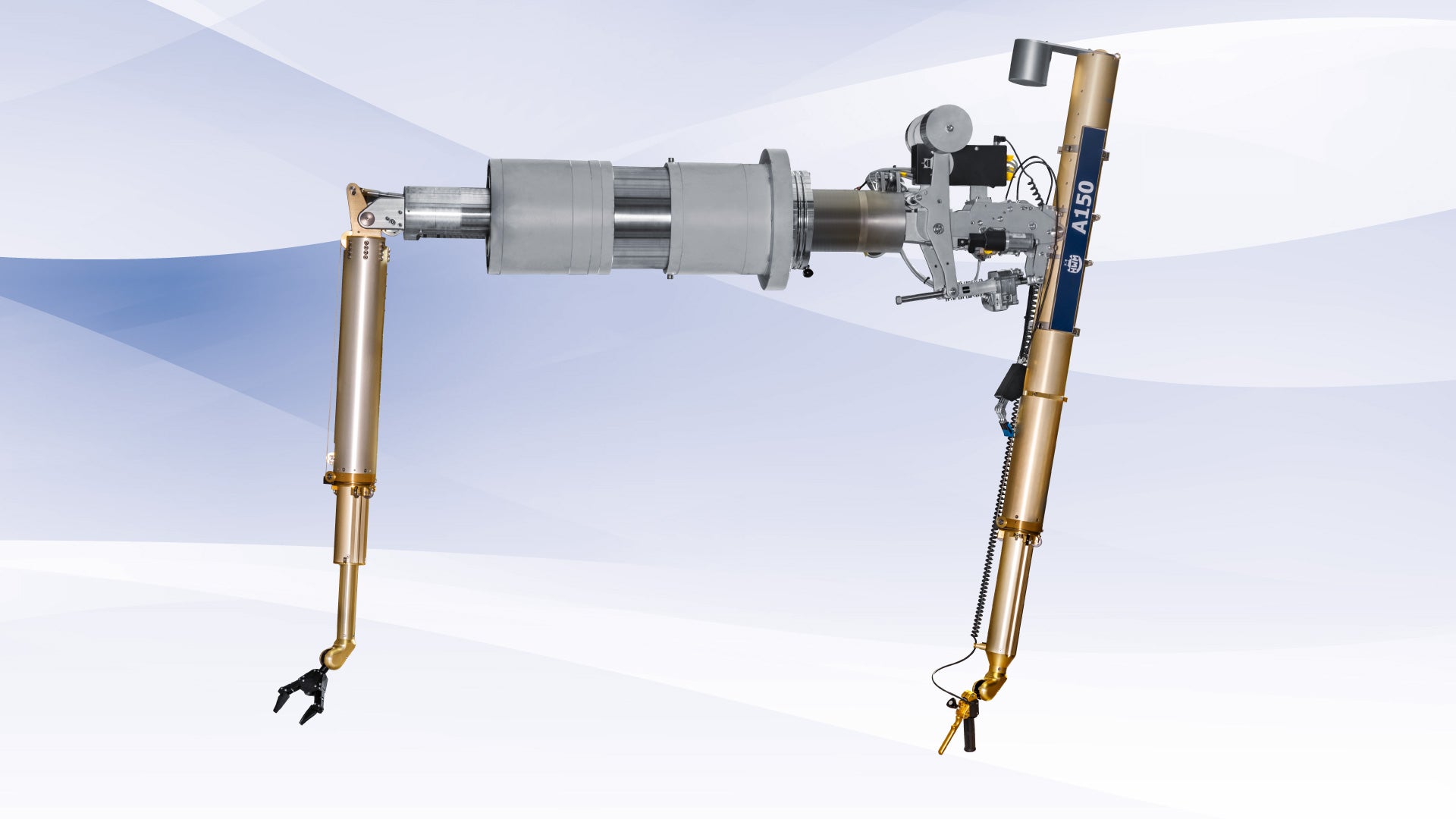

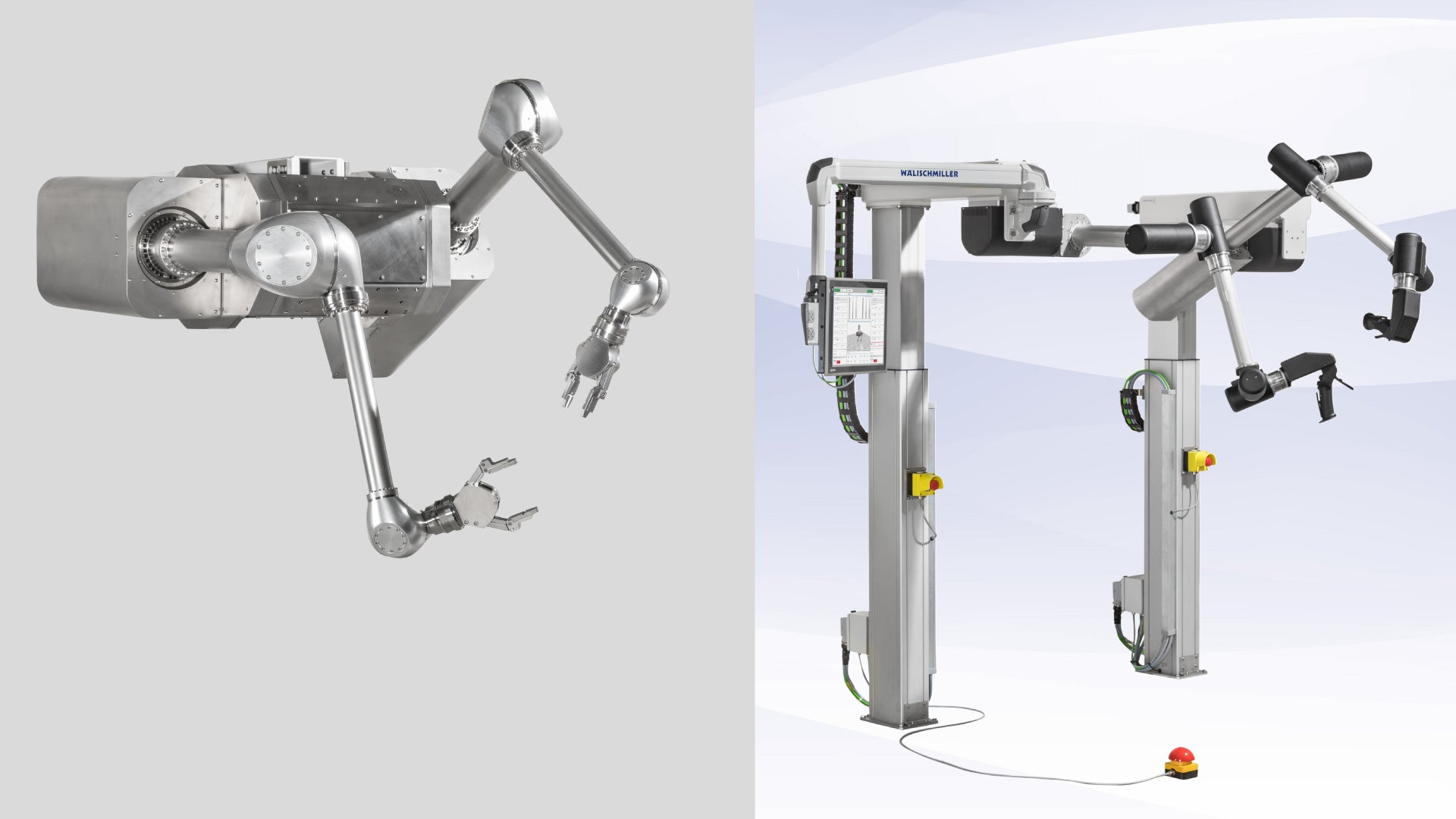

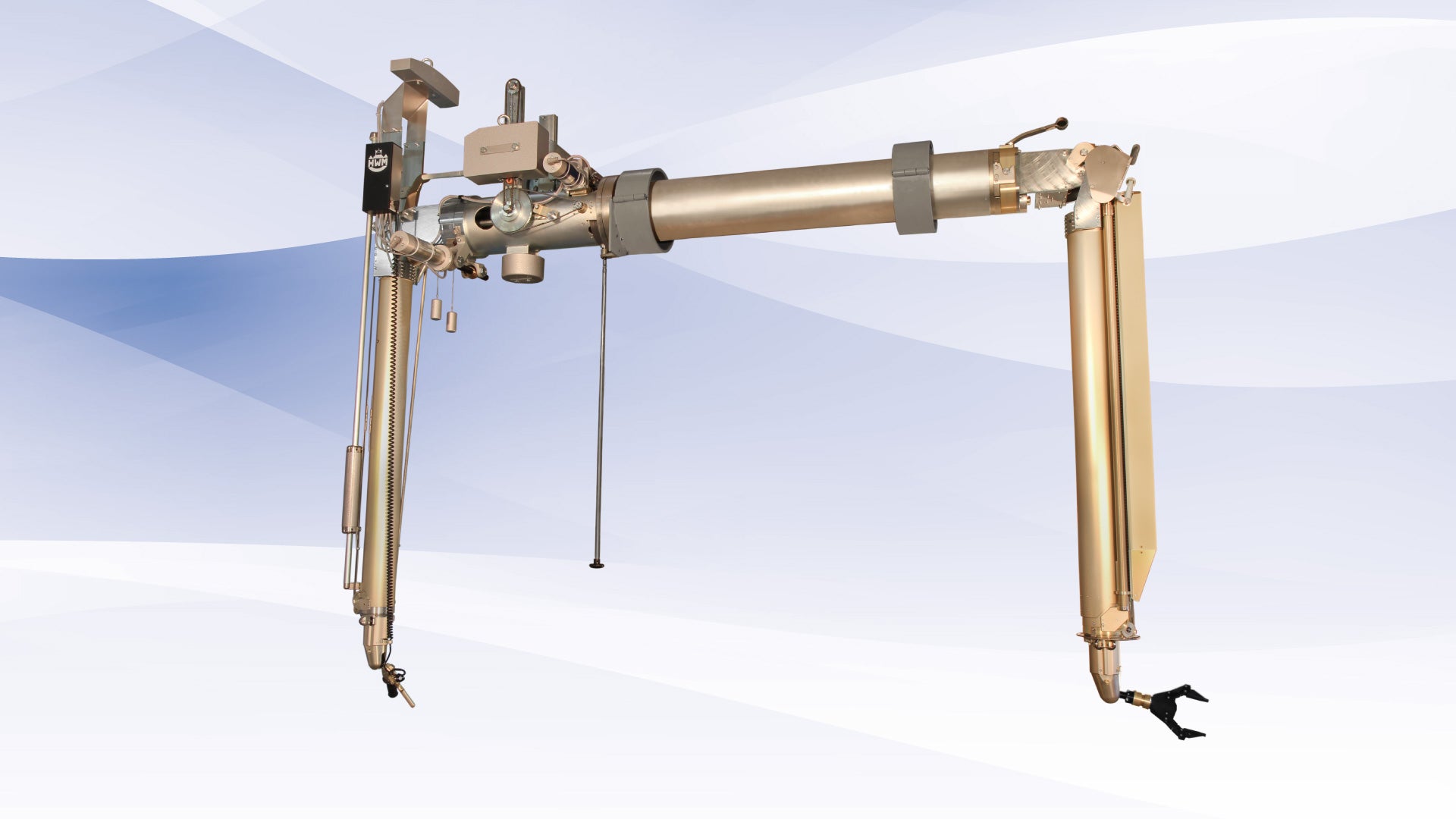

Experience the pinnacle of remote handling equipment for the nuclear industry with our exceptional lineup of manipulators. The A100 Telescopic Manipulator combines precise engineering with telescopic motions, enabling seamless access to remote and challenging areas within nuclear hot cells. The A200 Articulated Manipulator offers unparalleled dexterity, flexibly navigating complex environments while executing intricate tasks. For heavy-duty operations, the A1000 Power Manipulator reigns supreme, effortlessly handling substantial loads while upholding precision and control.

Our range of manipulators is meticulously crafted to meet the stringent requirements of the nuclear sector. From intricate maintenance tasks to hazardous material handling, our remote handling solutions are purpose-built to excel in nuclear environments. These advanced systems play a pivotal role in enhancing both operational efficiency and worker safety.

Precision Engineering for Nuclear Challenges

Precision engineering is the cornerstone of our solutions. We specialize in crafting components that adhere to the most rigorous quality standards, ensuring seamless integration and reliable performance. By combining cutting-edge technology with unmatched precision, we empower nuclear facilities to achieve unparalleled levels of productivity while maintaining the highest levels of safety and precision.

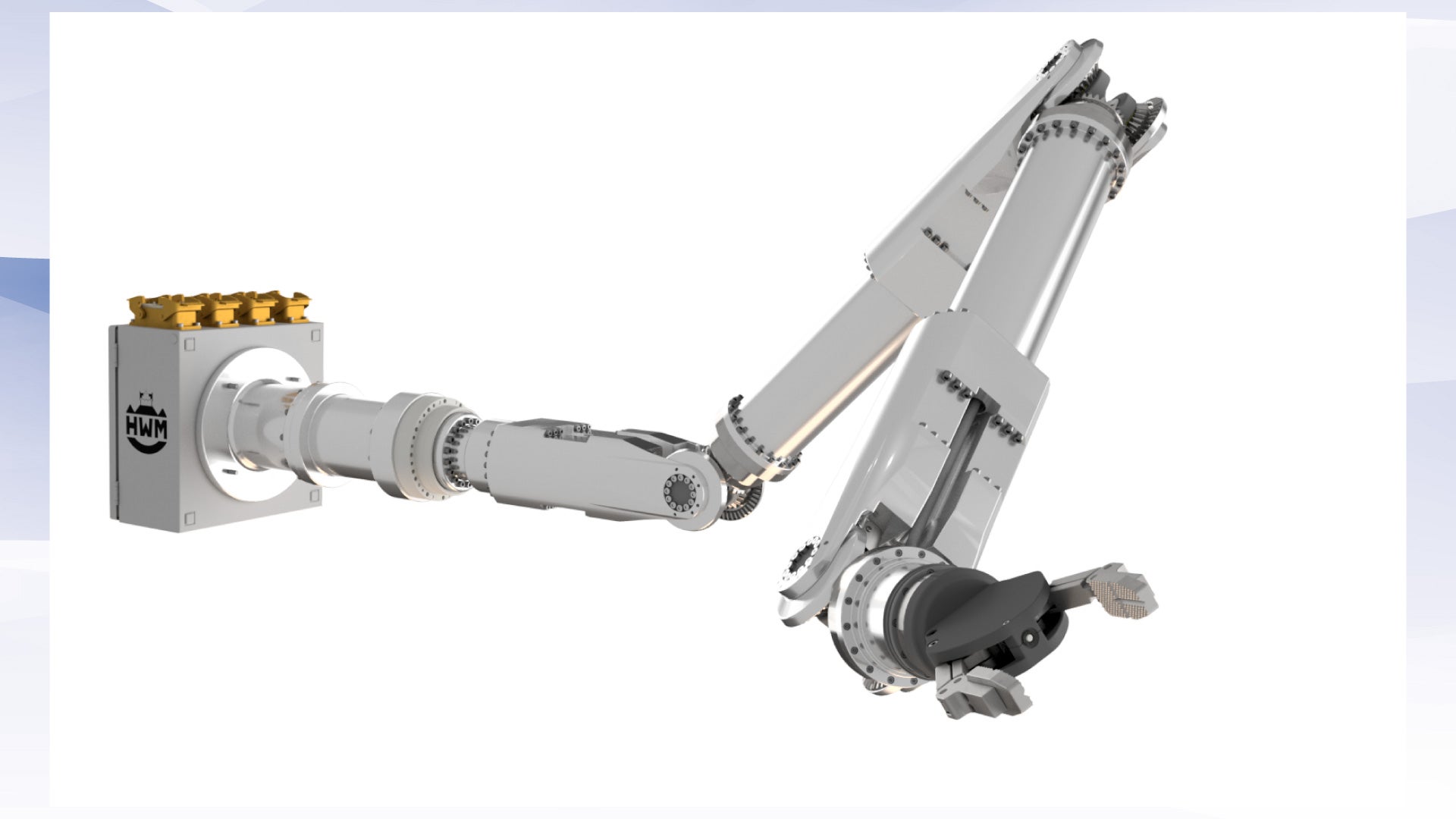

At the core of our remote handling solutions lies unmatched precision engineering. The LIROB showcases our dedication to lightweight yet robust design, enabling agile movement and precise manipulation within confined spaces. Our robotic system TELBOT® brings advanced intelligence to the nuclear realm, enhancing maintenance, inspection, and material handling tasks.

Tailored Nuclear Remote-Handling Solutions

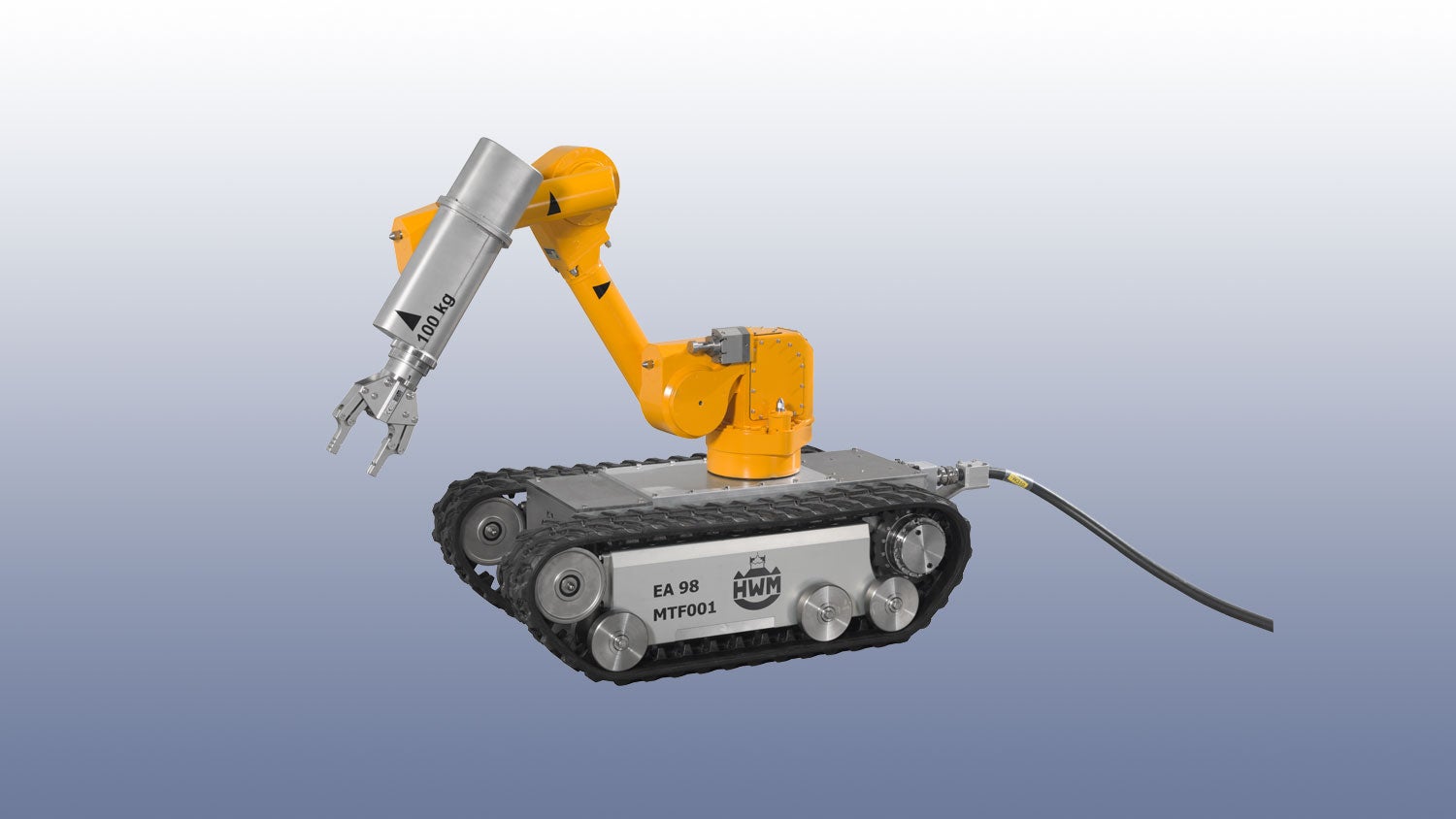

Understanding the unique complexities of the nuclear industry, we offer customized solutions that align with your specific needs. Our team of experts collaborates closely with nuclear stakeholders to engineer solutions that optimize processes and address industry-specific challenges. From nuclear research to decommissioning, our tailor-made automation systems streamline operations and elevate overall efficiency.

Elevating Safety and Reliability

Safety and reliability are paramount in the nuclear industry, and our solutions reflect this core principle. Our rigorous quality control procedures and thorough testing protocols ensure that every component and system meets the strictest safety standards. With a focus on reliability, we equip nuclear facilities with telemanipualtors and robots that contribute to enhanced safety measures and operational continuity.

Legacy of Excellence in Nuclear Industry Solutions

Wälischmiller Engineering has a storied journey that began in the 60s with a mission to deliver A100 manipulators to the research center in Karlsruhe. With a steadfast focus on the unique needs of this specialized industry, we have continuously evolved to address challenges and seize opportunities. Over the years, our dedicated team of experts has cultivated a deep understanding of nuclear applications, forging lasting partnerships and pushing the boundaries of what’s possible.

As we reflect on our journey, it’s clear that our commitment to innovation has been a driving force. This insight has propelled us to develop cutting-edge manipulators, such as remote handling vehicle V1000, LIROB, and A1000 Power Manipulator, each contributing to heightened efficiency and precision in nuclear operations.

Collaboration has been a cornerstone of our growth. Working closely with stakeholders in the nuclear sector, we’ve honed our expertise and embraced a dynamic approach to problem-solving. The result is a suite of products that meet and exceed industry demands, including the A200, designed for agile movement within confined spaces, and the TELBOT® robotic system, which has revolutionized maintenance, inspection, and material handling tasks.

Throughout our history, safety and reliability have remained paramount. Our stringent quality control measures and meticulous testing procedures ensure that every solution we provide meets the most rigorous safety standards. This dedication to excellence has solidified our reputation as a trusted partner in nuclear applications, with our manipulators and robotic systems contributing to enhanced safety measures and operational continuity.

Wälischmiller Engineering proudly stands as a beacon of innovation and reliability within the nuclear industry. Our exclusive remote handling solutions, featuring the A100 Telescopic Manipulator, A200 Articulated Manipulator, A1000 Power Manipulator, LIROB, and TELBOT®, exemplify our dedication to pushing boundaries, and surpassing expectations. With an unwavering commitment to the nuclear industry and a keen eye on emerging technologies, we are poised to further shape the landscape of nuclear solutions for our valued partners in the nuclear sector.