Our worldwide experience in the field of noise control is largely unsurpassed. Long before gas turbines were in general use for power production, G+H was developing, fabricating and assembling noise control components for jet engine test cells.

Our more than 50 years of experience and continuing research and development have resulted in the production of systems such as the resonator silencer which is considered a milestone in power plant noise control.

Clean air without impurities

We have the right air inlet system for power plants, no matter in which climatic zone a power plant is located. You can choose from a turnkey system or a combination of individual elements that can either be used for a new installation or a retrofit.

G+H Schallschutz offers you a complete range of air inlet systems required for heavy-duty gas turbine installations. Products include:

- Air intake ducts with optimal acoustic performance and flow dynamics

- Single or multi-blade dampers

- Silencers engineered for optimum acoustic performance and suitable for clean air environment

- Static filter systems with single or combined static filter systems

- Evaporative coolers

- Droplet catchers

- Anti-icing systems

- Complete process and instrumentation technology

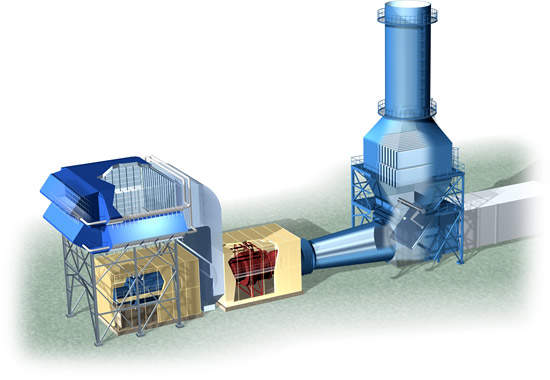

Exhaust gas systems

G+H Schallschutz has produced exhaust gas systems for over 40 years. From diffusers and exhaust gas plenums, to diverter dampers and bypass stacks to stack dampers and all the associated noise control equipment, we can supply you with a full range of products for heavy-duty gas turbine operation.

The internal or external insulation systems developed by G+H minimize heat loss and thereby help to increase the overall efficiency of the power plant while at the same time limiting noise transmission to the environment with proven silencer baffle designs and proven details to limit structure-borne noise through the components.

The G+H high-temperature resistant noise control systems are constantly being improved to meet ever-increasing temperature and flow requirements.

Designs are prepared to meet the exact project requirements and are engineered for optimum noise control, pressure losses, flow generated noise and maximum economic operation.

Our product range for exhaust gas systems include:

- Exhaust gas ducts and diffusers

- Rectangular and circular stacks

- Stack supporting structures

- High-temperature exhaust gas silencer baffles

- Diverter dampers

- Stack dampers

- Internal and external thermal and noise insulation for exhaust gas ductwork and heat recovery steam generators

- Metal and fabric expansion joints

Noise control from L to XXL

Legal requirements, as well as customers’ desires for minimising noise transmission from machines, power plants and plant components, are becoming more and more stringent. For this reason, G+H Schallschutz offers self-contained, easily dismantled and reassembled acoustic enclosures, for outdoor or indoor use, tailored to the required level of noise control.

G+H Schallschutz acoustic enclosures can be used wherever noise transmission from gas turbines, steam turbines, exhaust gas systems, generators and transformers.

Our acoustic enclosures can also be delivered and installed by us including necessary options according to the customers’ requirements, including:

- Fire extinguishing equipment

- Gas-tight enclosure construction

- Complete electrical installation

- Operating, access and maintenance platforms

- Noise attenuated air inlet and outlet systems for enclosure ventilation

- Man doors, doors and windows

Absorbing, resonator, and blow-off silencers

Absorbing silencers are used for broad spectrum noise sources such as occur at the inlet and outlet of gas turbines and cooling towers. Even at the highest temperature and flow velocities, the stability of G+H high temperature absorbing silencers is assured due to the use of special proven materials and the method of frame construction.

Resonator silencers are used in dust-laden media such as flue gas desulphurisation plants or in the attenuation of noise from single peaks in small frequency bands. Because of the complexity of the sound absorption mechanisms, the absorbing silencers are specifically designed for a particular use.

Blow-off silencers are used wherever steam or process gases have to be exhausted under high pressure into the environment.