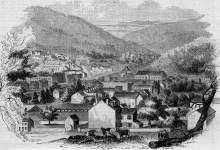

1790 – Hunter unwittingly ignites the ‘Coal State’

Necho Allen travels to Pottsville, Pennsylvania, for a hunting trip. At the end of a day’s fur trapping, Allen sets up camp at the base of Broad Mountain and lights a fire to keep warm through the night. The next morning, Allen wakes to discover that the small wood fire has expanded after igniting an outcropping of Anthracite coal. His discovery of the hard, compact coal leads the state of Pennsylvania on a path to becoming the ‘Coal State’.

1806 – US coal industry takes to the water

Abijah Smith learns of the vast anthracite coal deposits in Pennsylvania and travels from his home in Derby, Conneticut, to the Pennsylvanian borough of Plymouth with the intention of commercialising the resources. A year later, accompanied by his brother John, Smith excavates an estimated 50 tons of anthracite coal from the region and loads it onto an ark floated on the Susquehanna River. The load is shipped down the river to Columbia in Lancaster County, marking the first recorded coal shipment and a key moment in the industry’s early development. By 1930, an estimated 10,000 tons of coal is being shipped from the Plymouth and Wyoming County anthracite mines.

1828 – Hot blast fuels industrial growth

Scottish inventor and engineer James Beaumont Neilson patents the hot blast process while working at Wilsontown Ironworks in the village of Forth. The process, which involves pre-heating the air that is blown into a blast process, revolutionises industrial fuel efficiency and prompts a huge increase in demand for anthracite coal. Having quickly been adopted in America, the hot blast process leads to anthracite coal being used as the fuel in 45% of the country’s pig iron production within 15 years, fuelling significant growth in the coal mining industry.

1859 – Spanish submarine takes carbon scrubbing to new depths

Spanish artist and inventor Narcis Monturiol i Estarriol completes the construction of the world’s first air-independent and combustion engine-powered submarine. Built in his home city of Barcelona, the 7m long Ictineo I is created in order to aid coral mining. During the development process of the vessel, Estarriol discovers that he can double the amount of time the crew could spend underwater in the craft by forcing air through a container of calcium hydroxide to remove the carbon dioxide.

The process employed by Estarriol marks the first instance of a carbon scrubber being used, which continues to play a central role in reducing the carbon emissions of coal power.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalData

1918 – Unionist cries out for clean coal

Head of the United Mining Workers union Frank Keeney highlights the importance of clean coal to union members and its potential to help bring the First World War to an end by increasing the fuel efficiency of ships. In his speech, Keenan says: “I wish to call the attention of the membership of the organisation to still another duty which they own our government, themselves and our posterity — the absolute necessity of producing CLEAN COAL.” He adds: “Clean coal when placed in the bunkers of our ships means their increased speed and efficiency and that our soldiers and sailors are guaranteed more safety on the high seas against the submarines of the vicious Huns.” On less efficient coal, he says: “Every ton of dirty coal that is produced will retard the wheels of industry.”

1989 – MIT leads the way in research

Research into cleaning coal receives a significant boost with the initiation of The Carbon Capture and Sequestration Technologies Program at renowned US University the Massachusetts Institute of Technology.

The programme formalises the concept of cleaning coal power and other fossil fuel based energy generation methods as a research area and leads the way in developing the understanding and assessment of carbon capture technology, the economic models underpinning its development and the political issues. The program is quickly followed by others from around the world, culminating in a meeting of more than 250 scientists in Amsterdam in 1992 at the First International Conference on Carbon Dioxide Removal (ICCDR-1).

Recounting his experience at the conference, Howard Herzog, a senior research engineer at MIT, says: “Researchers were surprised to learn how many of their colleagues were already seriously investigating the subject. Attendees came to that meeting as individuals, but left it as a research community whose research progress has proven extraordinary in the decade since ICCDR-1.”

1992 – Earth Summit kick-starts climate change action

The United Nations Framework Convention on Climate Change treaty is negotiated at a conference informally called the Earth Summit in Rio de Janeiro in June.

The non-binding treaty has the set objective to “stabilise greenhouse gas concentrations in the atmosphere at a level that would prevent dangerous anthropogenic interference with the climate system”. The establishment of the treaty gives the issue of climate change global prominence and marks a major point in increasing pressure on the coal power industry to reduce its emissions and increase research into carbon capture and storage.

1997 – Kyoto Proticol sets the standard

The Kyoto Protocol is concluded and sets legally binding commitments on its signatory countries to reduce greenhouse emissions in order to try and avoid catastrophic effects of climate change. Signatories meet on an annual basis to discuss and assess progress in the area. In 2010, an agreement reached at a conference in Cancun, Mexico, states that members should take action to ensure that global warming is limited to below 2°C relative to the pre-industrial level.

2005 – IPCC identifies opportunities

The Intergovernmental Panel on Climate Change publishes a special report titled Carbon Dioxide Capture and Storage. In it, the researchers highlight the growing need to bring carbon emissions down on a global scale. Noting that fossil fuel-based energy will likely remain dominant until at least the middle of the century, the paper highlights the potential for carbon dioxide generated through coal power and other carbon intensive methods to be captured and stored in “geological formations, in the ocean, in mineral carbonates, or for use in industrial processes”.

2014 – Carbon captured coal power nears realisation

Canadian utility SaskPower announces that it is nearing completion of a $1.3bn retrofit programme at its Boundary Dam power station in Saskatchewan. Upon completion, the plant will become the first ever post-combustion coal-fired power plant in the world, bringing the much talked about benefits of carbon capture and storage into reality. The company has publicly stated that it expects the project reduce greenhouse gas emissions by one million tonnes of CO2 a year when it comes online at the end of 2014. While it is expected to be the first to come online, there are 17 other large-scale carbon capture projects underway around the world.

.gif)