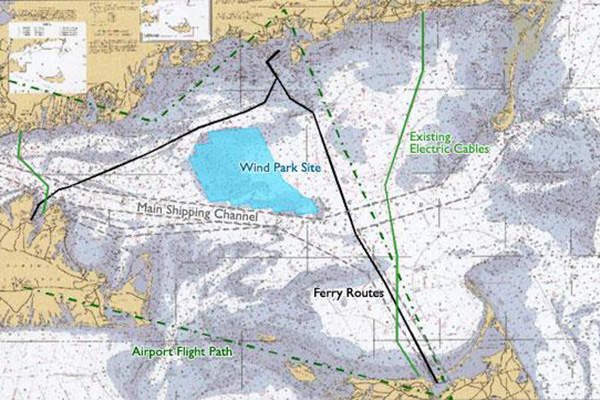

Cape Wind will be the first utility-scale offshore wind farm to be developed in the US. The 468MW wind power project located in federal waters off the coast of Cape Cod, Massachusetts, on Horseshoe Shoal in Nantucket Sound will feature 130 wind turbines with a 3.6MW capacity each.

The $2.6bn offshore wind farm is being developed by Massachusetts-based energy company Energy Management (EMI). Cape Wind applied for a two-year suspension for the operations terms of its commercial lease and received approval from the Bureau Ocean Energy Management (BOEM) in July 2015.

Construction on the oceanfront is expected to begin upon the expiry of lease suspension in July 2017.

The wind farm will produce enough energy to power more than 420,000 homes.

Cape Wind project development

As the first offshore wind power development in the US, the project experienced a prolonged development and permitting process. Application for the commercial lease of the offshore wind project was made to the US Department of Interior in September 2005. The department permitted a 25-year commercial lease in April 2010 after the project’s final environmental impact statement (EIS) was published in January 2009.

The project construction and operation plan (COP) was submitted in October 2010 and was finally approved by the US Bureau of Ocean Energy Management (BOEM) in September 2014.

Cape wind farm make-up and turbine details

Cape Wind will comprise 130 SWT-3.6-107 wind turbines from Siemens, arrayed in parallel rows in shallow waters. The turbines in each row will be 630m apart, while the rows will be approximately 1km apart from each other.

Each three-bladed and horizontal axis turbine, mounted on a tapered tubular steel tower with a 16ft base diameter, will have a rotor diameter of 107m and blade length of 52m. The pitch-regulated variable speed wind turbine will provide a rotor speed of up to 16 revolutions per minute (rpm), while offering a swept area of 9,000m². The cut-in and cut-out wind speeds of the turbine are 5m/s and 25m/s, respectively.

The height of the turbine towers, from the water surface to the blade centre, will be 258ft, while the lowest and highest blade tip heights from the water surface will be 75ft and 440ft, respectively.

Power generated by the turbines will be transferred through intra-array submarine cables to the Electric Service Platform (ESP) located near the centre of the wind farm and further transmitted to the shore.

The operations headquarters of the project is planned to be constructed along Falmouth Harbour on Cape Cod.

Construction

The turbines will be supported by monopole foundations driven deep into the seabed, and the towers will be bolted onto the foundations after fixing the transition pieces to the monopiles. Intra-array submarine cables will be jet ploughed 6ft into the seabed.

The offshore wind turbines will be installed by a fleet of vessels, including the R D MacDonald, the first special-purpose offshore wind installation vessel built in the US.

Cape Wind project financing

Cape Wind raised $1.3bn for the offshore wind project by April 2014. The US Department of Energy (DOE) issued a conditional commitment for a $150m loan guarantee for the project.

A consortium comprised Bank of Tokyo-Mitsubishi UFJ, Natixis and Rabobank are providing more than $400m in commercial debt for the project. A mezzanine debt of $200m is being provided by PensionDanmark, while a $600m funding commitment has been made by the Export Bank of Denmark (EKF).

Barclays Bank is the financial adviser for Cape Wind.

Power transmission and purchase from Cape Wind

The electric service platform (ESP) of the wind farm will work as an offshore substation, where the electricity will be transmitted through two 12.5mile-long submarine cables that will make landfall in New Hampshire Avenue, West Yarmouth. From the landfall site, the electricity will be transmitted through underground cables to the electric grid at Barnstable substation.

National Grid and NSTAR, two leading Massachusetts-based utilities, will respectively purchase 50% and 27.5% of the wind farm’s output under two separate 15-year power purchase agreements.

Contractors involved

A joint venture (JV) of Weeks Marine and Manson Construction was selected as the lead construction contractor for the offshore wind project in August 2014. The Boston and New England Maritime Trades Council and the American Federation of Labor and Congress of Industrial Organizations (AFL -CIO) will supply a skilled workforce for the JV.

A consortium consisting of Ramboll, Keystone Engineering and PMSS was chosen for the detailed design of the steel monopile foundations in May 2012. K2 Management has been serving as the project manager for Cape Wind since 2011.

Siemens was awarded the contract to supply the wind turbines and the ESP for the offshore wind project in December 2013. The company is responsible for the fabrication, installation and commissioning of the turbines. The scope of the contract includes a 15-year maintenance agreement for the wind turbines and ESP.

Siemens subcontracted the manufacturing of the ESP to Cianbro. Moffatt and Nichol Engineers designed the ESP for Cianbro.

UK-based company Tekmar was contracted in June 2014 to provide more than 200 of its TekLink cable protection systems (CPS) for the project’s inter-array and export cables. Tekmar is also supplying bellmouth and cable guide cones as part of the contract.

Prysmian Cables and Systems USA were contracted in March 2014 for the supply of intra-array and export power cables, and Caldwell Marine International were contracted for installing the underwater cables.

Lawrence-Lynch Corp is responsible for the upland construction work required for burying the electric cables. The company will also provide a channel for connecting the on-land electric cables with the submerged ocean submarine cable using directional drilling.

The geophysical and geotechnical survey team for the project was led by Fugro. ESS group was the lead environmental consultant and also prepared the COP for the project.