Competitive Power Ventures (CPV), jointly with GE and Osaka Gas, is developing the 1,050MW Fairview Energy Center in Jackson Township, Cambria County, Pennsylvania, US. Osaka Gas owns 50% of the under-construction power plant through its US subsidiary, while GE and CPV hold 25% each.

Announced in March 2017, the natural gas-fuelled power project is expected to serve up to more than one million homes. It will combine advanced power generation technology with clean natural gas and advanced emissions controls system to become one of the cleanest and most efficient conventional generation facilities in Pennsylvania.

Groundbreaking for the combined-cycle power plant was conducted on 24 October 2017, while commissioning is planned for 2020. The project is expected to create between 300 and 500 jobs during construction and 21-25 full-time jobs when operational.

Fairview Energy Center make-up

To be located on a 30-acre site in Johnstown, the combined-cycle facility will consist of two 7HA.02 high-efficiency air-cooled gas turbines in a two-on-one configuration, coupled with two heat recovery steam generators (HRSGs) and a steam turbine.

The turbines and the associated HRSGs will be equipped with a selective catalytic reduction (SCR) system to minimise nitrogen oxide (NOx) emissions and an oxidation catalyst to minimise carbon monoxide (CO) and volatile organic compound (VOC) emissions.

Auxiliary equipment for the project will include a cooling tower, a natural gas-fired auxiliary boiler, two natural gas-fired dew point heaters, two ultra-low sulphur diesel (ULSD) fired emergency backup generators, and a firewater pump.

Natural gas blended with ethane will be the primary fuel for the plant.

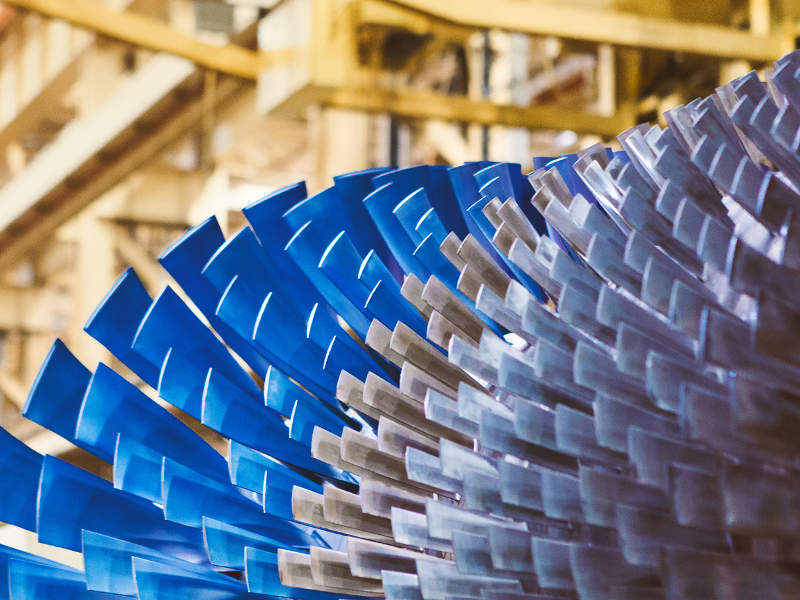

Turbine technology

The H-Class turbine comes with a simple configuration and modular system, the installation of which takes 10,000 lesser man-hours than the 7F.03 gas turbine.

The 7HA turbine offers a combined-cycle efficiency of more than 61% and is capable of ramping up from start command to full load in ten minutes. It can generate up to 100MW a minute in a 2×1 configuration. It is also capable of delivering full power to the grid within 30 minutes.

Power generation at Fairview Energy Center

Ambient air will be injected into the compressor section of the two combustion turbines through an inlet air filtration system. It will pass through inlet evaporative cooling, which involves a series of warm ambient temperatures and low relative humidity.

It will be mixed with natural gas/fuel in the fuel/mix combustion stage of the combustion turbine and will pass through various stages of the turbine, where the thermodynamic and/or gas energy will be converted into mechanical energy.

Rotating shafts will transmit the mechanical energy to the generator, which will be directly coupled to the power turbine. The generator will convert the mechanical energy into electricity.

Hot gases produced in the combustion turbine will be transferred to the HRSG through an exhaust transition duct, where waste heat will be captured and converted into steam. Steam produced in the HRSG will be used in the ST to produce additional electrical power.

Transmission

The generated power will be fed to the Pennsylvania, New Jersey, and Maryland (PJM) Interconnection electric grid through the FirstEnergy/PJM 500kV transmission line.

A new electrical substation will be constructed on the project site to enable the connection.

Natural gas supply

Natural gas for the energy centre will be sourced from an interstate natural gas transmission line owned by Spectra Energy, located north of the project site. A natural gas supply pipeline, which is approximately 12in in diameter, is proposed to be constructed from the point of connection to the project.

Financing for Fairview Energy Center

CPV, GE Energy Financial Services, and OGUSA obtained $700m in senior debt financing in three tranches from a group of 16 international lenders.

The lenders group includes Credit Agricole Corporate and Investment Bank, MUFG, BNP Paribas, CIT Bank, NAB, Industrial and Commercial Bank of China, New York branch, Commonwealth Bank of Australia, DNB Markets, and others.

Industrial Bank of Korea acted as the coordinating lead arranger for the funding sourced from Korea.

Milbank, Tweed, Hadley and McCloy acted as the advisors for the lenders group.

Contractors involved

Kiewit was awarded the engineering, procurement and construction (EPC) contract for the project.

GE was awarded a contract in March 2017 for the supply of two gas turbines, a steam turbine, generators, and required control equipment for the plant.