Located in Ama-gun, Aichi, Japan, Nishi-Nagoya Thermal power plant is owned by Chubu Electric Power.

In 2010, the company decided to refurbish the 40-year-old power station in order to reduce the quantity of fuel consumed, which approximated 0.4 million tons (Mt), and to curb the CO₂ emissions, which amounted to roughly 1.4Mt.

The plant is now being replaced with a cleaner and more efficient power-generating facility. Units 1 to 4 at the plant were decommissioned in November 2013 for this reason, while units 5 and 6 were decommissioned earlier, between 2002 and 2003.

The dismantling of Units 1 to 4 paved the way for the installation of a new set of two natural gas-fired combined-cycle units, designated 7-1 and 7-2 and together known as Group Number 7.

The refurbishment and construction works began in January 2014. Unit 7-2 became operational in September 2017, while Unit 7-1 was expected to be operational in 2018.

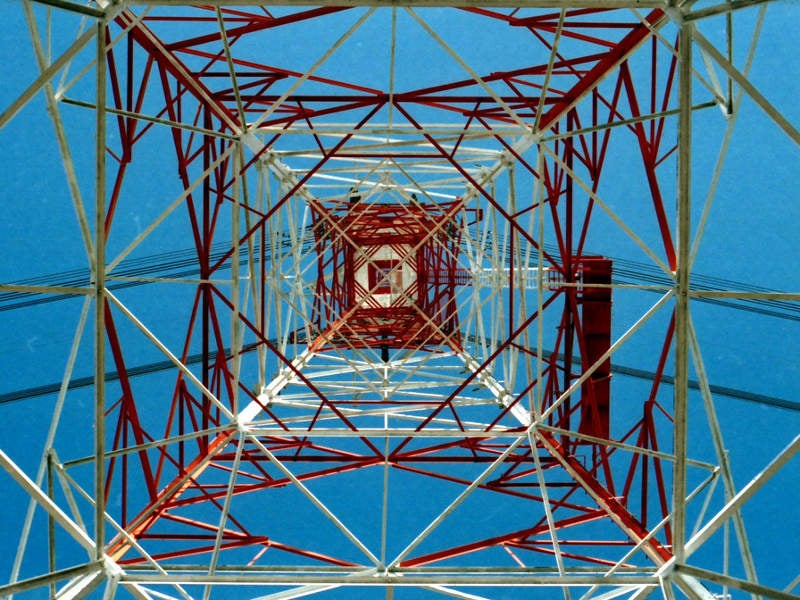

The refurbished plant will have the capacity to supply more than 2.2GW of power to the grid, which is equivalent to powering 400,000 average homes in Japan.

Nishi-Nagoya CCGT plant make-up

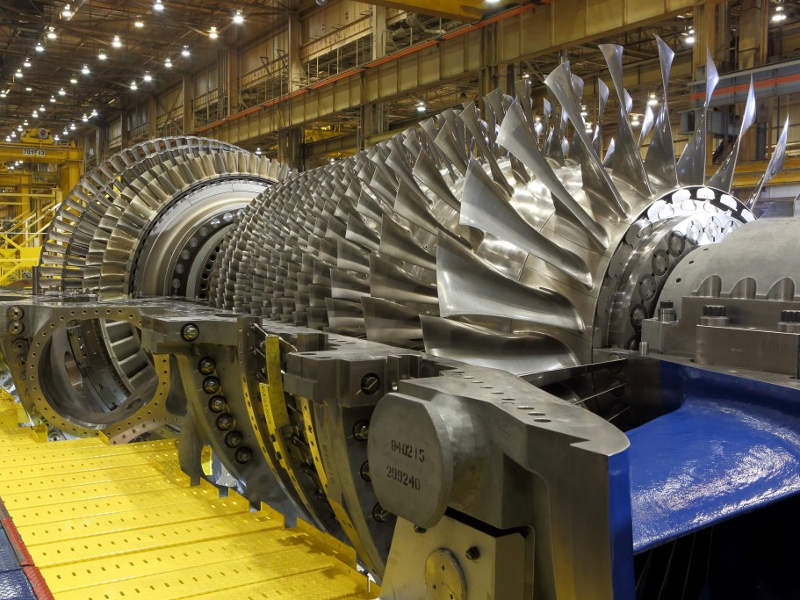

The new combined-cycle plant will include six GE 7F 7-series gas turbines integrated with Toshiba’s high-efficiency steam turbines and generators. The turbines will be arranged in lateral rows in a mirrored layout, having one block on each side.

To achieve high efficiency at the baseload of operation, the plant utilises a three-on-one multi-shaft system consisting of three gas turbines and three heat recovery steam generators, as well as one steam turbine.

The technology used in the plant combines the benefits of a high thermal efficiency of 62% with emissions reduction and flexibility.

Details of GE’s FlexEfficiency technology

The 7F 7-series is GE’s biggest and most efficient gas turbine, which helps increase the thermal efficiency as well as reduce fuel consumption and CO₂ emissions.

The turbine’s fuel flexibility allows it to run on a wide range of gas and liquid fuels such as high-ethane (shale) gas and liquefied natural gas (LNG). The 7F 7-series gas turbine can be ramped up to full load in less than 30 minutes, resulting in greater grid stability with alternate energy sources.

GE’s FlexEfficiency technology harnesses the use of natural gas and enables power plants to cater to the changes in power demands, match the fluctuating grid conditions and adjust the fuel supply accordingly.

Contractors involved

United Steel Structures supplied various components, including casing, ducts and field steam components for the heat recovery steam generators of the plant.

Toros Constructions is providing support structures for selective catalytic reduction (SCR) of the six units of the plant.

History of Nishi-Nagoya thermal power plant

The Nishi-Nagoya thermal power plant was constructed between 1960 and 1970 to cater to the surging power demand due to rapid economic progress in Japan at the time.

The plant had six units, out of which four commenced operations between 1970 and 1972. Units 1 and 2 had an output capacity of 220MW each, while units 3 and 4 had 375MW each, and units 5 and 6 had 500MW each. The combined output capacity of the six units was 2.19GW.

The plant used heavy oil, crude oil and naphtha as fuel, functioning primarily as a critical middle load power plant, which provided a stable electricity supply to Nagoya city and its surrounding area, and a peak load power plant between 2000 and 2012.