BOA Group has played a key role in a project to enhance the safety of nuclear power plants in the event of earthquakes and other natural disasters.

The SILER project, the study of ‘seismic-initiated events risk mitigation in lead-cooled reactors’, was established to study the risks associated with seismic initiated events in Generation IV Heavy Liquid Metal reactors and develop adequate protection measures.

As part of an 18 member team comprising of nuclear research organisations, universities, test facilities, special component manufacturers and engineering contractors, BOA SFZ was selected to design and manufacture metal bellows and expansion joints that will be required to compensate for thermally and seismically incurred movements in piping systems that cross the gap between isolated and non-isolated structures of nuclear power plants.

The expansion joint systems studied by BOA included the main steam and feed-water piping of Lead -cooled Fast Reactors (LFR). The LFR systems were selected for the prototype expansion joint designs due to the extreme design conditions of 185 bar at 425°C for the main steam and 200 bar at 335°C for the feed-water piping. Expansion joints capable of withstanding such pressure and temperature conditions have never been built before.

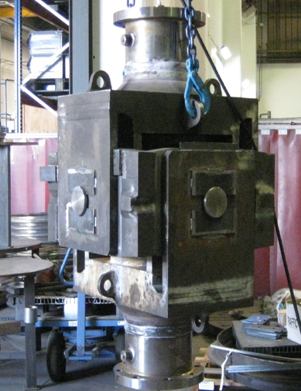

BOA SFZ designed the Gimbals type expansion joint by utilizing FEA and simulation software. The bellows were manufactured by means of hydraulic forming and final assembly at BOA’s facility in Chassieu near Lyon, France.