Canduct Industries produces and stocks an entire line of insulation components for the liquid-filled power and distribution transformer market.

Whether your need is pre-assembled winding kits for large power transformers or duct strip for distribution transformers, or anything in between, Canduct is able to meet all of your needs, large or small.

Canduct is conveniently located in a state-of-the-art 104,000ft² facility in Ontario, Canada, which is a short distance from the US borders at Buffalo or Detroit.

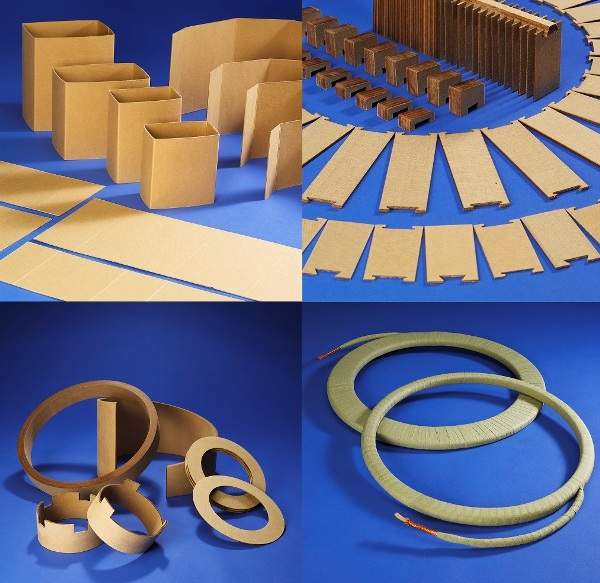

Pre-assembled winding kits

Pre-assembled winding kits have become very popular with liquid-filled power transformer manufacturers. Canduct offers complete kits that are ready for assembly, which provide the following advantages:

- Reduction of production costs and increase of production capacity by minimizing processing times.

- Reduction of freight costs by consolidating products and delivery dates

- Cost saving in purchasing because only one item is ordered for each transformer

- Reduction of warehousing costs for insulation material

All pre-assembled winding kits are fully constructed, shrink-wrapped and ready for shipment.

Fabricated insulation components

Canduct produces an entire line of fabricated insulation components for the power and distribution liquid-filled transformer market. All of the company’s insulation components are produced from the purest pressboard or laminated wood materials.

Canduct has a proven record of superior ply-bond adhesion that ensures the integrity and durability of their product offering. Components the company offer include:

- Cylinders

- Step blocks

- Cleat and leads

- Spacers

- Sticks and strips

- Cooling assembly

- Pressure plates

- Static rings

- Washers

- Winding tubes

- Molded parts

- Tempered hardboard

Duct strip paper

Duct strip is the core product on which Canduct was founded. It was the company’s sole product when it was founded more than 30 years ago.

Today, two of the most sophisticated machines in the industry produce up to 6,000ft² of product each hour. The uniquely engineered automation process allows Canduct to produce any size and configuration you require, all within the strictest tolerance standards. This makes Canduct duct strip a recognized and accepted material around the world.

Duct strip is a commodity that distribution transformer manufacturers rely on every day. It must be beyond reproach and their supplier has to be reliable and responsive. The integrity of the product and their business depends on it, making Canduct duct strip a world-class, renowned product.

Crepe paper tubing

Canduct produces an entire line of crepe paper tubing. The Politube® brand is recognized in the transformer industry as top-quality insulation for leads in liquid-filled transformers.

Canduct Politube crepe tubing is produced from the finest crepe material the industry has to offer. Made from multiple layers of crepe kraft paper, and with high purity and high-oil absorption as well as good electrical dielectric strength, Politube tubing is an industry leader.