While a carbon-neutral combustion engine still sounds like something out of this world, such a development may soon become reality, taking the energy sector by storm.

The secret to the success of carbon-neutral fuels to drive the change is that the manufacturing process encapsulates carbon dioxide, making a significant contribution to tackling emissions and the climate change resulting from it.

As synthetic fuels promise to allow vehicles such as cars and even planes to effectively switch to an eco-friendlier approach, Synhelion is already making strides towards commercialising solar fuel and closing the carbon cycle in an innovative way.

From sun to power

Since Synhelion produced the first-ever solar fuel from air and sunlight, which withstood the challenges of real field conditions two years ago, the company has scaled up the particular components of the technology to industrial size and has developed additional processes for the production of synthetic fuels.

The process, which efficiently converts concentrated sunlight into heat, is based on taking the carbon dioxide and water out of the air, turning it into gas, and then liquefying it to fuels that could be used by conventional engines.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

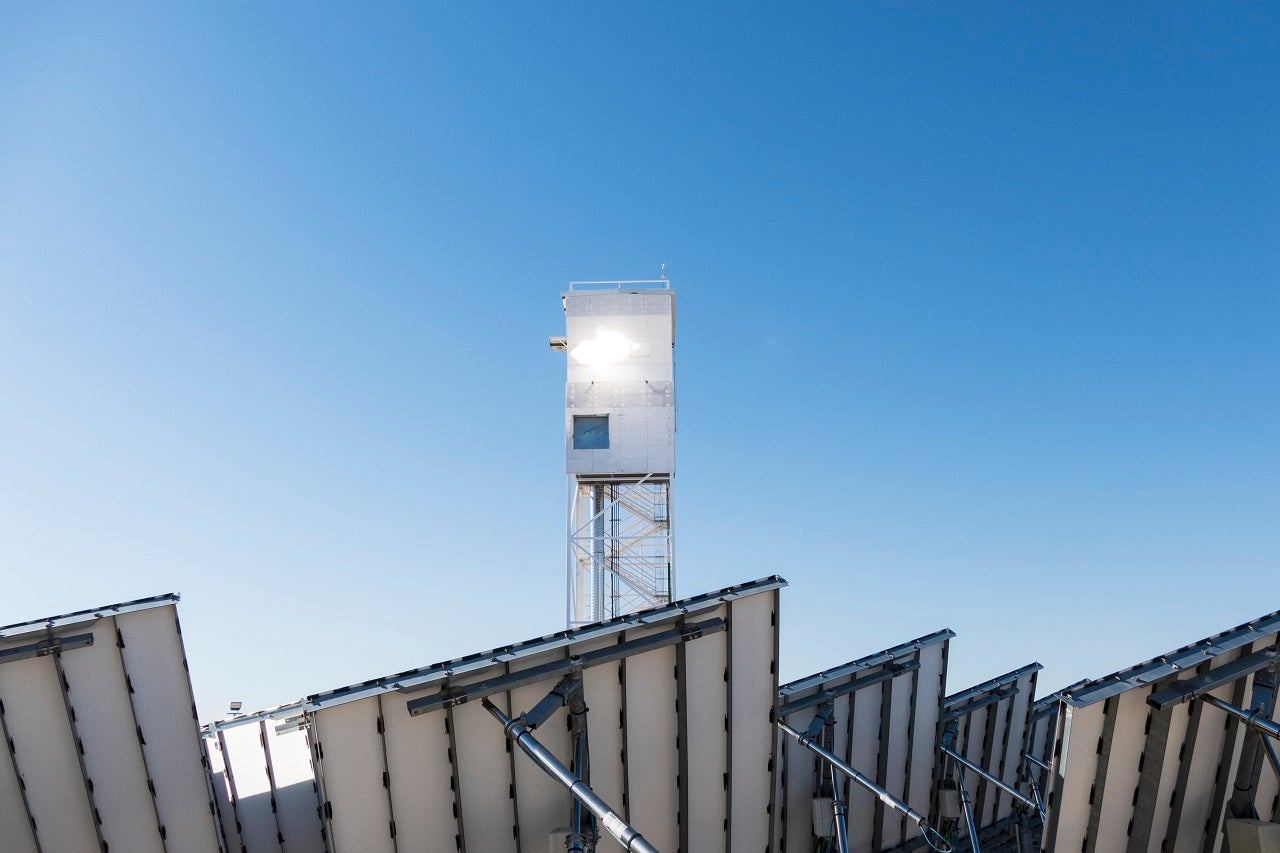

By GlobalDataBy using concentrated sunlight in a test facility, Synhelion relies on a mirror field, which tracks the sun and, as it focuses sunlight to the top of a tower, accumulates very high-temperature heat, which then drives a reactor that produces syngas, needed to make any type of fuel like jet fuel, diesel, and gasoline by established industrial processes.

Carmen Murer, head of corporate communications at Synhelion, says: “This could have a huge impact on the world because our solar fuel technology is scalable to cover global fuel demand. Worldwide, the transportation sector alone uses three billion tonnes of liquid fuel per year and, in theory, we could produce that amount of fuel with our technology.

“I think that could be a huge paradigm shift and have a significant impact on the energy transition.” The partnership Synhelion has established with global consulting and engineering company Wood will combine the company’s solar technologies with Wood’s novel hydrogen reforming reactor technologies, aimed at further accelerating the path to market maturity.

In addition to this, Synhelion and Wood are jointly designing, building, installing, and commissioning a complete system on the solar tower at the Jülich site of the German Aerospace Centre.

“We are combining industrial reforming technology from Wood with our innovative solar technology to produce sustainable synthetic fuels. We can deliver solar process heat of up to 1500°C, which is about three times more than existing concentrated solar applications typically produce.

“And this means that we can go to the market more quickly, so it’s very important for the industrialisation of our technology to have a partner like Wood,” Murer says.

The plant will demonstrate the production of syngas, a mixture of hydrogen and carbon monoxide, on an industrial scale. The plant will also be used to produce solar thermal hydrogen.

As Synhelion is preparing to move to the use of bigger and bigger towers, the company is getting ready to build its first industrial-scale plant next year, with fuel production planned to commence at the beginning of 2023.

Ultimately, all company fuels are also scheduled to become available on the market in 2023.

Efficiency of synthetic fuels

Synthetic fuels can be made in a few ways, for example, by taking carbon dioxide or monoxide from the atmosphere and synthesising it with hydrogen taken from water.

In a different scenario, it is also possible to create them from biomass, such as burning logs and plants, before turning them into a gas that is then blended with hydrogen.

When it comes to the eco-friendliness of synthetic fuels, they are largely renewable, but whether they are particularly eco-friendly depends on how the processes of making them are staged and conducted. As their production requires a lot of energy, the use of electricity or fuels from non-renewable sources may go against the point of synthetic fuels in the first place.

Synthetic fuels are also currently seen as one of the most promising solutions for an efficient reduction of carbon dioxide emissions, especially for aviation and long-distance transport. Moreover, they meet the high requirements of the modes of transport in terms of energy density and can replace fossil fuels without too many infrastructural adjustments.

“The technology is basically reverse combustion. We take carbon dioxide and water and use solar heat to turn them back into fuel,” Murer says.

After Synhelion evolved from the Swiss Federal Institute of Technology, ETH Zurich, in 2016, it has been working on this vision to replace fossil fuels with clean synthetic fuels, by closing the carbon cycle.

Compared to other technologies, Synhelion sees the efficiency of this process as higher than, for example, power to liquids, thanks to the reduced amount of conversion steps, which makes it a very direct approach.

Advantages and obstacles

A prime example of where synthetic fuels might become key is aviation. Since aggregation for this sector is simply not possible to electrify, liquid fuels are not going away anytime soon, standing out with their great abilities as an energy carrier, which is dense in energy.

However, as Synhelion’s technology is compatible with existing infrastructure, not just the planes that are already flying but also the whole distribution system that is established, the company is confident that the fuels that they produce can be distributed with the same systems we now run on fossil fuels.

While this ‘exotic’ method of using energy from the sun comes with its obvious benefits, its associated challenges are mainly financial, because the development and deployment of hardware require a substantial amount of money and brave investors who believe this could be a big game-changer in the energy market.

Another challenge Murer opens up about is the price of synthetic fuels as this innovative development, like many renewable options, is fighting to come down as close to the price of fossil fuels as possible in order to become a viable and preferred option by energy operators and users alike.

“We want to have a big impact and really help the world to decarbonise. We can only do that if we offer competitive prices.

“We all know that we don’t really pay the real price of fossil fuels at the moment and the bill of environmental damages that this is causing is only going to be paid later. So it’s a bit of unfair competition, but there’s also a lot of political action being taken now to change that. And we see that it is going in the right direction,” Murer concludes.