Offshore access solutions provider Ampelmann has developed a new angular boom tip that allows workers to safely and efficiently install jackets for wind turbines.

Ampelmann was awarded an engineering, procurement, construction and installation (EPCI) contract by the global offshore contractor Seaway Heavy Lifting to develop the angular boom tip.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataThe new solution will be used to install a total of 84 turbine jackets at the Beatrice Offshore Windfarm project in Outer Moray Firth, Scotland. It will provide a secure connection for safe gangway transfer between the 5,000t heavy lift vessel (HLV) Oleg Strashnov and the 2,500t HLV Stanislav Yudin.

These rounded gangway tips can fit on the majority of offshore wind turbines or offshore assets.

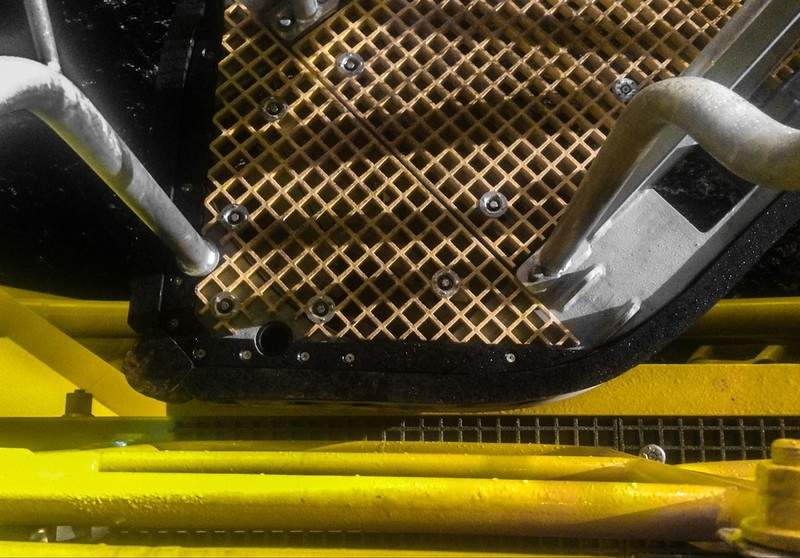

Ampelmann provided a custom V-shaped tip for the project at the end of the 25m gangway to offer workers easy access to build and manage each new wind structure.

The company carried out the design, development and installation of the detachable tip for approximately two months.

The solution is currently integrated on the Beatrice project using Ampelmann’s A-type motion compensated gangway system, which is capable of transferring people with zero movement in significant wave heights of up to 3m.

Ampelmann offshore wind sales and business development manager Friso Talsma said: “Though the tip is a quite a straightforward piece of steel, the rubber covered angular shape now allows us to land at difficult angles as small as 45°, while eliminating the risk of gaps between gangway and structure.

“It’s a new innovation, tailor-made for this particular project and overcomes a significant safety and potentially costly challenge faced by the operators to ensure safe access to the structures.”

Scheduled to become fully operational in 2019, the Beatrice Offshore Windfarm is estimated to be capable of supplying power to approximately 450,000 households.

Construction for the project started this year.