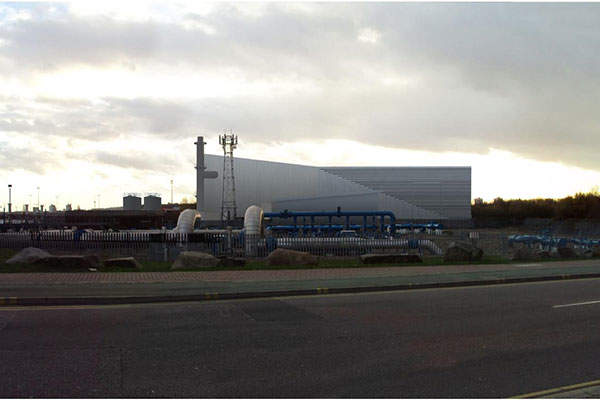

UK-based green utility company 2OC set up a combined heat and intelligent power (CHiP) plant at Beckton in east London. The plant is located adjacent to the National Grid Gas Pressure Reduction Station.

The main source of fuel for the plant is the fats, oils and greases (FOG) that are thrown away by households and restaurants.

The plant has an annual output of 130GWh of electricity, while the installed capacity is 19MW. It operates at an electrical efficiency of more than 65% and provides power for approximately 40,000 households.

J Murphy & Sons was awarded the contract to construct the plant in April 2013.

Fats, oils and greases as fuel

Beckton’s power project got clearance from Newham Borough Council and the London Thames Gateway Development Commission in 2009.

The plant was constructed on 2OC’s own land near Thames Water’s desalination plant and sewage treatment works site. Operations began in the second half of 2015.

The plant uses FOG for generating electricity. Thames Water, Britain’s biggest water company, provides the fuels required for electricity generation.

Thames Water collects food fat, low-grade cooking oil and other greases. Thames Water also collects animal fat and waste vegetable oils from households, restaurants and food product manufacturers and supplies the same to the Beckton plant. It supplies 300t of FOG a day to the plant, which forms half of the fuel requirement.

The contract period with Thames Water for the supply of FOG is 20 years. The plant is also compatible to use other renewable fuels such as bio-methane.

Technology at 2OC’s Beckton-based power plant

2OC installed its CHiP station at the Beckton power plant.

The plant is equipped with a MAN B&W type 10L35MC-S diesel engine. The two-stroke, low-speed engine runs on bio-fuels. The engine can generate 6,450kW of power at a rate of 214.3 rotations a minute.

The plant is equipped with a 13MW generation unit and turbo expander. Some of the heat generated by the engine is converted into thermal energy with the help of the turbo expander, to produce additional power.

Heat recovery cycles of the CHiP technology increase the thermal efficiency of the plant. Heat from the engine is supplied to the adjacent gas pressure reduction station owned by the national grid, replacing the gas boilers used to preheat the gas.

Advanced control and instrumentation equipment was installed at the renewable plant.

Distributing power from the CHiP facility

2OC sells 75GWh of the electricity generated at the plant to Thames Water, while the remaining 55GWh is sold to the national grid. A £200m ($304m) deal was signed between Thames Water and 2OC regarding the purchase in April 2013. 2OC supplies power and heat to Thames Water’s sewage treatment works at Beckton, as part of the 20-year agreement.

Finances and contracts for Beckton’s fat-fuelled plant

The Beckton power plant was financed by iCON Infrastructure, EEA Holdings and Deutsche Bank.

J Murphy & Sons was responsible for the Beckton plant’s engineering works, material procurement and construction. The £70m ($105m) valued contract was awarded through a tender system.