The Bellefonte Nuclear Power Station is located adjacent to the Tennessee River near Hollywood in the state of Alabama, USA. Spread over 1,600 acres, the plant consists of two partially built units, each having 1,256MWe pressurised water reactors (PWR). The plant is owned by Tennessee Valley Authority (TVA).

The proposal to complete the construction of Bellefonte nuclear plant was made in 2008 and the same was approved by the Nuclear Regulatory Commission (NRC) in February 2009.

TVA is currently assessing the completion of Units 1 and 2 scheduled to be operational by 2017 and 2021 respectively. The project’s ‘terminated’ status was upgraded to ‘deferred’ status after thorough inspections by the NRC in January 2010.

The site for the construction of new Units 3 and 4, which will house two 1,100MWe AP 1000 reactors, has also been chosen and approved by the NRC.

Bellefonte history

Construction of the plant began in 1974 but was suspended in 1988 due to a fall in both demand and the price of electricity in the region. Around $6bn had already been invested in the construction of the two reactor units. The two reactors were supplied by Babcock & Wilcox.

At the time of suspension, construction of Units 1 and 2 was complete up to 88% and 58% respectively. Subsequent asset recovery activities and plant inspections, however, revealed that construction was complete only up to 55% and 35% respectively.

The construction permit of the unfinished plant was suspended in 2006 by the NRC upon a request from TVA.

At the time of terminating the construction permit, TVA had notified the NRC that it would continue using the existing environmental site permit and also maintain major components such as water intake and discharge facilities, cooling towers and transmission switchyards, turbines and auxiliary buildings.

TVA has since then been conducting regular inspections at the site to ensure that none of the equipment or material causes any environmental or health hazards.

TVA has, however, trimmed its plans to construct only Unit 1 instead of the potential four-unit Bellefonte Nuclear plant. The decision was the result of falling electricity sales and rising cost of cleaning up the huge coal ash spill at the Kingston Fossil Plant in December 2008.

The ash dike of the plant was ruptured resulting in heavy fly ash release across 300 acres of the surrounding area. The accident had damaged nearby waterways, rivers and homes.

The final approval for the completion of Unit 1 is still pending and is not expected until 2011. The project completion cost is estimated to be between $4.3bn and $4.7bn. In August 2010, TVA authorised $250m towards engineering, licensing and procurement of long-lead materials of Unit 1.

TVA is currently in the process of completing the integrated resource plan before the receipt of final approval from the NRC.

Plant details

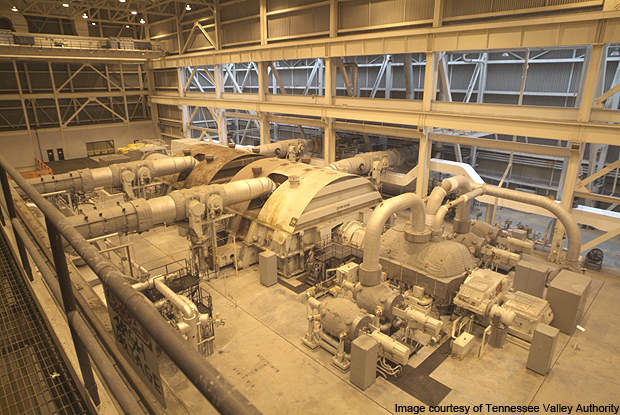

The partially constructed Bellefonte Unit 1 pressurised water reactor will have two steam generators weighing 500t each.

The generators will produce superheated steam to drive the turbines and generate electricity.

Reactors

In October 2010, TVA awarded a contract to Babcock & Wilcox Canada to design and manufacture two steam generators. The generators will be delivered by 2015 depending on the final approval.

The engineering and development contract has been awarded to Areva who will carry out the engineering work at the existing site and also at the new digital instrumentation and control (I&C) system, an advanced control room.

Technology

The pressurised water reactor (PWR) is a second generation reactor used in most of the nuclear plants currently operating in the US. It uses light water as primary coolant and also as neutron moderator.

The coolant is pumped around the primary circuit at 275°C by powerful pumps capable of consuming 6MW each. It is heated as it flows upwards in the reactor core to a temperature of 315°C.

The high pressure in the primary coolant loop retains water in a liquid state despite high temperatures.

The high pressure is achieved by maintaining the pressuriser temperature at 345°C.

This results in a sub-cooling margin of 30°C, which is the difference between the pressuriser’s temperature and the highest temperature in the reactor core.

Automatic heaters and water spray control the temperature in the pressuriser accordingly.

The primary coolant transfers heat from the steam generator to water in the lower pressure secondary circuit. The water in the secondary circuit evaporates into saturated steam to be used in turbine.

The cooled primary coolant returns to the reactor vessel to be heated again.