The Statkraft osmotic power plant at Tofte, Norway, is the world’s first osmotic power or salinity gradient power generation plant. The prototype, which is based on osmotic technology, was constructed and is owned by Statkraft. It is operated by SINTEF Energy Research, a research division of SINTEF Group.

On 24 November 2009, the prototype was opened by the Crown Princess Mette-Marit of Norway. The prototype plant has a designed capacity to generate 10kW of electricity. The completely commercialised osmotic power plant will be ready by 2015.

The plant generates renewable and emissions-free energy and thus contributes to eco-friendly power production.

It is estimated that the osmotic technology will produce 1,600TWh-1,700TWh a year, which is about 13 times the hydropower generated in Norway annually. Out of the total estimated osmotic power of 200TWh that is expected to be generated in Europe, 12TWh will be generated in Norway.

Tofte plant history

The generation of electric energy through osmosis was developed by Sidney Loeb during the 1970s. Work on the theoretical potential of the osmotic power was carried out by Torleif Holt and Thor Thorsen during the 1980s.

In 1997, a project to implement the osmotic power generation technology was established by Holt and Thorsen in collaboration with renewable energy company Statkraft.

EU funds were awarded to osmotic power research in 2001. The funds awarded accelerated the research work being carried out, leading to the first environmental study also being carried out in 2001. Statkcraft filed the first patent for osmotic power membranes in 2003, after which the company opened a test facility at Sunndalsøra.

The prototype of the osmotic power plant was constructed in 2008 at Tofte, Hurum, in Buskerud County, Norway.

Construction of the osmotic power plant

Osmotic power plants are built where freshwater flows into the sea. The concentration of salt in the seawater should be sufficiently high to generate the required pressure.

The premises of Sodra Cell Tofte, a paper pulp factory, were leased by Statkraft for the construction of the osmotic power prototype. The site is an industrial area with access to freshwater and seawater.

Construction of the main building was completed in 2008. By December 2008, construction of the purification plant that maintains full control of the raw water was completed up to the first floor.

The installation of water pipe systems outside the power plant was carried out in February 2009, while the installation of pipe systems inside the powerhouse began in March 2009. The modular plant consists of 66 pressure pipes, a turbine, pressure exchangers and a cleaning unit. The pressure pipes have about 2,000m² of rolled-up membranes rolled on the inside.

Osmosis technology

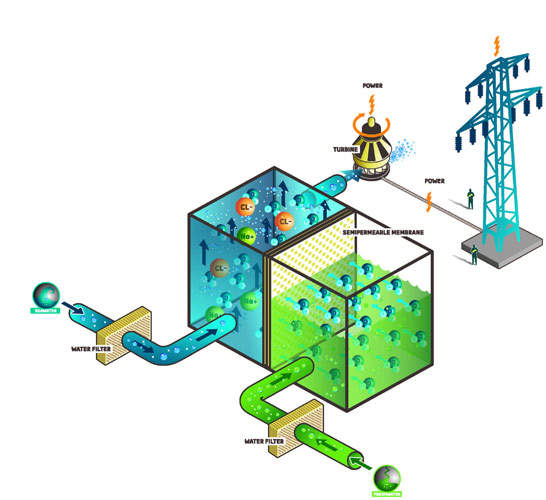

Osmosis is a natural process used to generate power by considering the enormous energy released when freshwater meets saltwater. In this process, the water is transported through a semi-permeable membrane – an organic filter with extremely small holes.

The plant incorporates two chambers separated by an artificial membrane to store freshwater and saltwater. The pressure generated by the transfer of water through the membrane in one direction is used to generate electricity.

The pressure in the seawater chamber will be increased as the salt in the seawater draws the freshwater through the membrane.

The plant uses hundreds of meters of pipes to channel saltwater and freshwater into the power plant. The pressure generated will be equal to that of a 120m water column and can be used in a driving turbine to generate electricity.

The osmotic power plant will not discharge any pollutants to the atmosphere, nor will it affect the seafloor or the river habitat.

Development of the Statkraft plant

The prototype is being used mainly for testing and development purposes because of its limited production capacity. The development activities included creating a membrane that draws the required quantity of water to create enough pressure to run the turbine.

Statkraft and research groups in Norway, Germany and the Netherlands are involved in the development of the membrane technology.

Project finance

The entire project is being funded by Statkraft with the aid of Enova SF (Enova) and the Research Council of Norway.

Approximately Nkr100m ($18m) was invested by Statkraft in the development of the power plant’s technology.

The prototype was supported by the Royal Norwegian Ministry of Petroleum and Energy’s Enova, while the research work was backed by the Research Council of Norway.