When built, the 1,600MW San Joaquin Valley Energy Center (SJVEC) will be the cleanest and lowest cost fossil-fuel facility in the USA. SJVEC will be located in Fresco County, next to the Mendota Wildlife Management Area and within the City of San Joaquin’s industrial zone. The plant is however suffering delays because capacity additions in California have outpaced peak load growth, meaning that existing resources can supply reliable and competitively priced electricity through 2005.

After the severe electricity shortages in the spring and summer of 2000, there has been an enormous drive to expand electricity production in California. Long-term power contracts have been negotiated between the state and several power companies, including Calpine, HDPP, Capitol, Cabazon and Whitewater Hill. These negotiated contracts cover a range of benefits including reduction in costs, improvements in conservation controls and the construction of 11 new power plants.

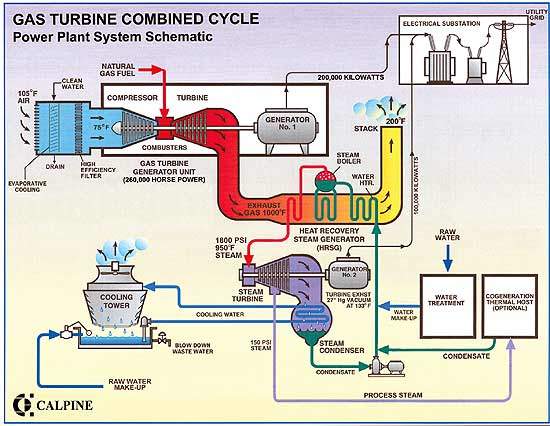

One of the main plans to help stem supply shortfalls was Calpine’s new project at the San Joaquin Valley Energy Center (previously the Central Valley Energy Center), which will provide deregulated electricity for the open market. The 1,600MW (of 3,000MW demand) will come through combustion and steam turbine generators (CGT and SGT).

The plant is expected to cost upwards of $550 million. When completed, it will use natural gas and will be engineered with advanced emissions control technology. It is expected to spend around $10 million on materials and supplies in the California region.

PROJECT TIMING

Construction was expected to commence in Q3 2002, taking between 24 and 27 months to finish, and be completed for testing in Q2 2004. Initial plans were for the plant to go online in Q3 2004.

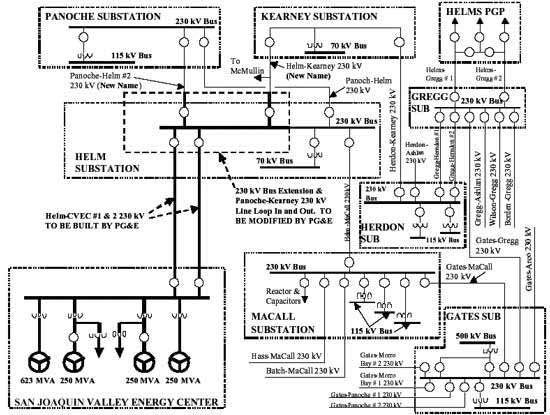

The plant will be built adjacent to the Pacific Gas and Electric’s substation. They have been commissioned to carry out a $100,000 study to identify transmission system impacts. The SJVEC will be connected to the transmission system by looping into PG&E’s Panoche-McCall and Panoche-Kearny 230kV, 1,500ft transmission lines. Calpine will build the plant, bus and substation, and PG&E will construct and operate the lines. Approximately 2,900ft of 70kV transmission line will be rerouted to the substation.

The baseload capacity for the SJVEC is approximately 835MW. To help meet peak summer demand, Calpine has incorporated a larger steam turbine, fogging and duct firing, allowing the facility to generate an additional 230MW. The peaking capacity depends on the need and the temperature, for example in summer months the maximum output will be 1,062MW at a temperature of 100°F, and in the spring output will be 1,097MW, at a temperature of 61°F.

TURBINES AND GENERATORS

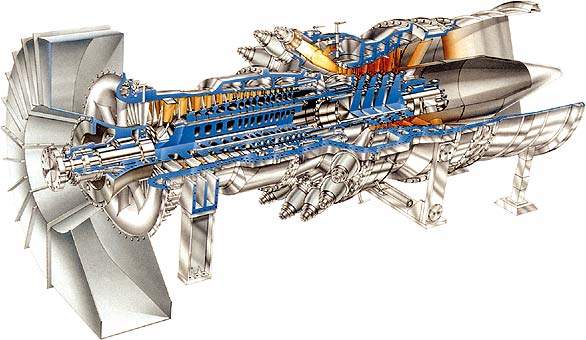

The combined cycle plant will consist of three CGTs, each producing 180MVA and having a 15/230kV step-up transformer, and one SGT producing 550MVA with a 18/230kV step-up transformer. The CGTs will be Siemens-Westinghouse 501FDs, and equipped with dry low nitrogen oxide (NOx) combustors and steam injection power augmentation capabilities. The plant will use a selective catalytic reactor to control emissions of NOx. Also, an oxidation catalyst and inlet air filter will control emissions of carbon oxide, volatile organic compounds and fine particle matter.

This combined-cycle design and advanced emissions control technology will make the SJVEC 90% cleaner than older gas-fired power plants. In fact, health, environmental and consumer groups have supported Calpine’s use of this technology as a way to advance clean air goals. This enables Calpine to lower energy costs while improving air quality.

Other plant features include a surface condensed steam generator, a de-aerating surface condenser, a mechanical-draft cooling tower and various associated auxiliary equipment.

LIQUID NATURAL GAS

The fuel for the power plant will be brought in from 20 miles away by a new underground 24in pipeline. This fuel has been cooled from a gas to a liquid, making it easier to transport (it takes up approx. 1/600 the storage space of natural gas) and less likely to catch fire. Further, the project will be extremely fuel-efficient, using 40% less natural gas than old-technology projects.

The plant uses wet-cool technology, which draws water for cooling along a 27in diameter pipeline from 21 miles away at the Fresno-Clovis Wastewater Treatment Facility. The plant’s 16-cell cooling tower will require 7,000gpm of the effluent, which will come from six new shallow extraction wells. Calpine will sink these wells at 75-100ft deep.

The plant will be a zero-discharge facility meaning that no wastewater produced will be disposed off-site. Instead wastewater containing dissolved solids will be dried in a drum drier and the resulting cake disposed of in a municipal landfill.

Domestic water will be provided via a 1-mile pipe from Jan Joaquin, and sewage expelled through a 2.5-mile sanitary pipeline.

CALPINE

Calpine currently has 12,100MW of generating power in operation and 14,200MW in construction, and is running the largest construction program ($15 billion) in the power industry.