Premier Power Ltd has built a £200 million, 600MW combined cycle gas turbine power station on a brown field site in Ballylumford, Northern Ireland. Full commercial operation began in 2003. The new station is adjacent to an existing station and uses the existing infrastructure, including natural gas supply and on-site electricity distribution facilities.

The thermal efficiency of the new plant is above 50% and electricity is generated at 15kV and 18kV, stepped up for underground transmission. When the new plant was completed, the three 200MW steam turbines in the existing station were decommissioned. The remaining units in the existing thermal station remained in operation.

COMBINED CYCLE GAS TURBINES

Combined cycle gas turbines can now give cycle thermal efficiencies of over 50%, significantly higher than the 33% or so of the existing plant at the power station. If the steam turbine or waste heat recovery unit goes off line due to problems, or for maintenance, the new plant can continue to operate at lower thermal efficiency (around 35%). Here, heat from the gas turbine is exhausted through a bypass stack to the atmosphere (open cycle operation).

THREE SIEMENS GAS TURBINES

PB Power provided project management services, including engineering design review and audit, specialist technical support and advice, technical coordination management, construction supervision and QA/QC functions.

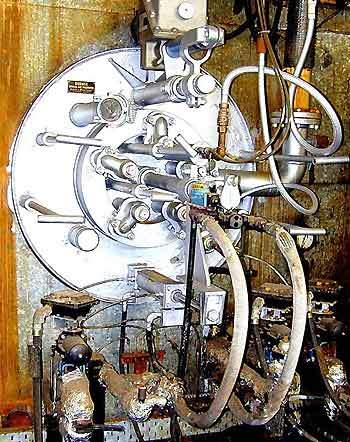

The plant comprises two Siemens V94.2 gas turbines and one Siemens V64.3A gas turbine combined cycle unit. Ansaldo Energia is the turnkey contractor for the design, procurement, construction and commissioning contract.

15/18kV VOLTAGES STEPPED UP TO 275/110kV

Electricity is generated at medium voltage (15kV and 18kV) and converted to 275/110kV by step up transformers to meet Northern Ireland Electricity (NIE) transmission system requirements.

The high-voltage electricity is transferred by underground cables to existing outgoing feeder connections in an adjacent NIE switch-house. From there, it goes through the transmission system to the electricity users. The medium voltage is also stepped down to provide plant auxiliary power supplies. The plant is therefore self-contained when operating.

NATURAL GAS WITH LOW-SULPHUR DISTILLATE BACKUP

The plant’s primary fuel is natural gas, delivered to Ballylumford Power Station from the North Sea. The gas goes via the BG National Transmission System and Premier Transco subsea pipeline from Scotland to Northern Ireland at high pressure (15bar to 75bar). Gas pressure is reduced at Pressure Reducing Stations (PRS) before supplying the low NOx gas/oil burners on the main plant boilers.

The gas turbines also operate on low sulphur distillate liquid fuel if the gas fuel supply is interrupted. When working on liquid fuel the gas turbine NOx emissions are controlled to meet environmental legislation requirements. This is done by injecting water or steam into the fuel combustion process to lower the flame temperature. No liquid injection is required for NOx suppression when operating on gas.

Steam exhausted from each steam turbine is fed to a condenser and the condensed steam is returned to the steam generator by pumps. The process is continuous and replenished as required from a make-up system to allow for losses.

WATER RETURNED TO LARNE LOUGH

The cooling water for the condenser is provided by a once-through system using brackish water extracted from and returned to Larne Lough, next to the plant site. The returned water is at quality levels and temperatures to meet environmental legislation.

Water for make-up to the steam cycle and plant is provided from a desalination plant, again extracted from the Lough. This raw water is further treated to provide the steam cycle and plant quality requirements, and stored in tanks on the site. Liquid effluent, which is discharged from site into the cooling water discharge, is monitored and treated to ensure that all waste meets statutory legislation requirements.

The layout and design of the plant uses proven combined cycle technology and takes into consideration environmental impacts, in particular noise, safety, emissions and visual appearance.