A 130MW biofuel-fired boiler plant using bubbling fluidised bed (BFB) combustion was built in Sweden, close to the town of Örnsköldsvik in 2008. The final testing was conducted in late 2008. The contract, worth €50m, was awarded to Aker Kvaerner by Övik Energi AB.

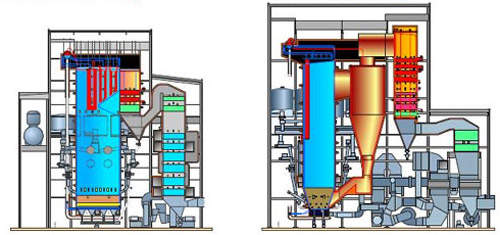

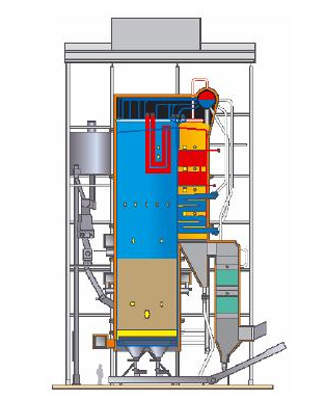

Kvaerner Power’s HYBEX® boilers use BFB technology, and are suitable for a wide range of fuel from thermally dried bark to high moisture forest residue. The boiler has a steam capacity of 130MW and steam data temperature and pressure of 540ºC and 139 bar.

Fluidised bed boilers

Kvaerner Power is part of the Aker Kvaerner group. It supplied the BFB power boiler, which burns biofuels. The delivery included engineering, procurement and construction of the power boiler, the boiler building, and the electricity and instrumentation systems.

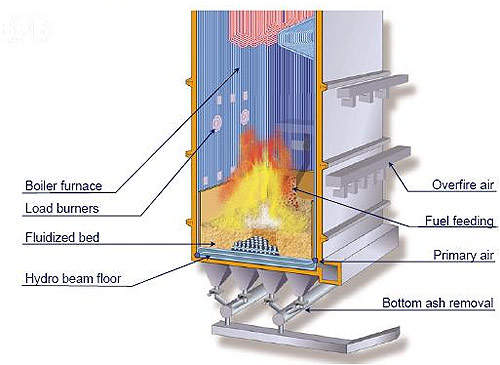

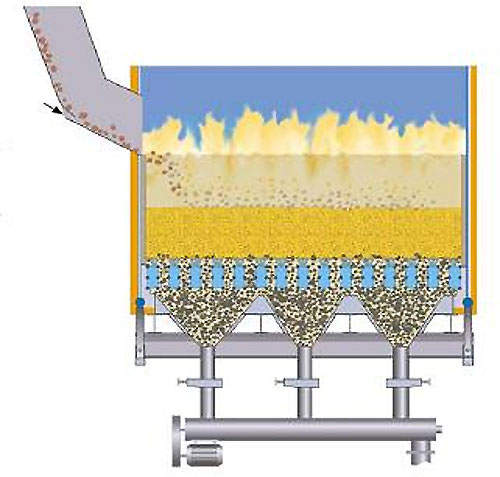

Fluidised bed combustion allows a range of fuels with wide variation in heating value and fuel type. Combustion is controlled, and produces very high burn-out of ashes, low emissions and high thermal efficiency.

They are simple in construction, highly reliable and require low maintenance. They offer several advantages over traditional grate technology, including multi-fuel capability.

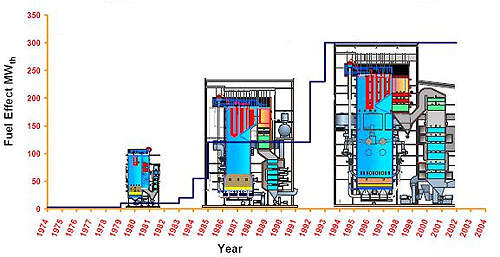

Kvaerner produces two types of fluidised bed boilers, the HYBEX which produces 20–300MWth from biomass and recycled fuel and the CYMIC which produces 50–600MWth from biomass, recycled fuel and coal.

The company’s hydro beam floor allows the use of demanding fuels. The water-cooled air beams have extended free removal area with easy removal.

Even medium-scale biomass power plants need subsidised electricity prices. Fuels are often collected within 100 to 200km radius from the plant in trucks. The plants can use wood fuel industry residues like sawdust, round logs and other forest fuel, willow and recycled wood.

Biomass generally produces only electricity. Plant efficiency (net electricity/fuel energy) is between 31 and 34%.

Örnsköldsvik construction

Övik Energi AB is a community-owned, limited company

which produces district heating locally, and electricity for the national net. The company is expanding its existing power plant, and has chosen biofuels to support the EU’s ambitions to cut carbon dioxide emissions.

The overall plant supplies a centralised district heating network, with new areas having recently been added. As part of this work, Övik Energi contracted KWH Pipe Thermopipe to install large Wehotherm district heating pipe elements in Örnsköldsvik.

The pipes were laid in 200m lengths below the Moälven river bed. They run at least 4 to 5m underneath the river bed and, at their deepest, some 20m below ground level. The district heating elements consist of a steel pipe surrounded by polyurethane foam as heat insulation and, on top of that, by an external PE casing.

The pipes from the Vaasa factory were delivered to Örnsköldsvik in 16m lengths and welded together on site into two 200m lengths.

The district heating pipeline connects the Själevad area to the large district heating power plant. The new main pipeline, which is more than 4km long, cost Övik Energy some €830,000.

Restructuring

Kvaerner has designed and manufactured some of the world’s

largest recovery units and biomass-fired fluidised bed boilers.

The company focuses on the 5–60MW(e) range and above. It has recently secured contracts for power boiler modernisations in Sweden, Lithuania and Slovakia.

Kværner ASA went through a number of restructuring processes in 2004 and 2005. Most of the businesses and operational activities were either spun off in separate entities or sold off.

Aker Kvaerner was established in April 2004 and includes most of the previous Kvaerner businesses providing engineering and construction services, technology products in oil and gas, refining and petrochemicals, pharmaceuticals and biotech, power generation, pulp and paper, and mining and metals.