Petrochemical company Technip is building a hydrogen plant at oil company Cepsa’s Huelva refinery, Spain. Cepsa has placed an Engineering, Procurement and Construction (EPC) contract worth approximately €60m. The plant will give Cepsa an essential feedstock for producing cleaner-burning low-sulphur fuels and will also raise feedstock availability for Cepsa’s petrochemicals segment.

The plant will have a capacity of 68,700m³ of hydrogen per hour, using high quality steam from Technip’s segregated / dual steam system. Technip’s operations and engineering center in Zoetermeer (the Netherlands) will complete the contract, with support from its centre in Barcelona.

The project is expected to be completed in the fourth quarter of 2009 and is part of Cepsa’s major expansion plan to meet the growing demand for middle distillates in Spain.

EXPANSION OF HUELVA REFINERY

The Huelva refinery produces a number of oil-derived products, which can be divided into two streams. The first produces Cumene, Phenol Acetone and AMS while the second produces methylamines and derivatives. The products are used in industry, agriculture, construction, cars and pharmaceuticals.

The refinery processes around 100,000 barrels a day, and Cepsa has recently announced plans to nearly double its refining capacity by 2010. The projects will raise jet kerosene and diesel fuel production by 3.2 million tons per annum (tpa). Total capital expenditures until 2010 will amount to €1,650m, €1,144m of which will be assigned towards expanding middle distillate capacity at Huelva, creating employment for 150 people.

Key projects include the construction of a new hydrocracking-type conversion facility with a capacity of over two million tpa which will produce middle distillates.

Raising Cepsa’s total crude oil distillation capacity only 17% will increase middle distillate production by 39%, thereby reducing its dependence on imports.

The spike in demand for automotive diesel on the European market and the consequent decline in gasoline consumption, compounded by the increase in air traffic, have all led to a widening shortage of kerosene and diesel fuels, which in Spain’s case, requires importing roughly 13 million tons of these products each year.

These projects will join a Light Naphtha Aromax Reformer that will produce 220,000tpa of benzene and 75t per day of hydrogen. The refinery will therefore raise its total benzene production to 361,000tpa and hydrogen production to 165t per day.

In March 2007, Foster Wheeler was awarded the contract for new crude, vacuum and gas recovery units. The crude distillation unit will have a capacity of 90,000 barrels per stream day (BPSD), the vacuum distillation unit capacity will be 30,500 BPSD and the capacity of the gas concentration unit will be around 148t per hour.

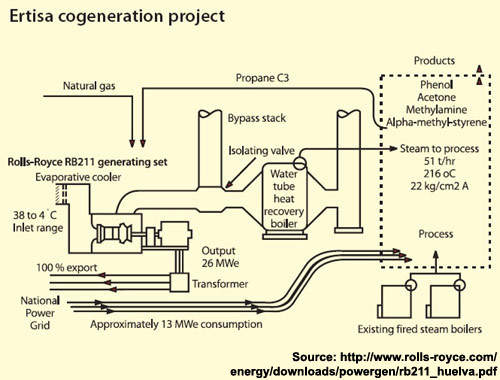

EXISTING COGENERATION ON SITE

In 1997, Rolls Royce produced a 26MW cogeneration project to produce electricity and steam for Huelva, operating with Ertisa Petroleum. The refinery demands a maximum load of 16MW, with excess being exported to the national grid. The exhaust from the RB211 is put through a heat recovery boiler that supplies the 52t of steam per hour for the refinery’s production needs.

Although the RB211 runs on natural gas, as part of an ongoing efficiency programme on the site, trials have been undertaken using propane as fuel. Huelva produce 40,000 tons of propane gas each year for sale but there is sufficient remaining to power the engine.

The price of propane varies throughout the year, which means that when the cost of natural gas is high the engine can be switched to propane to cut costs.

CEPSA – SPAIN’S SECOND LARGEST OIL COMPANY

Madrid-based Cepsa (Compania Espanola de Petroleos SA) is a unit of France’s Total SA (TOT), and Spain’s second largest oil company. Cepsa is a diversified energy company whose core business is the refining and marketing of petroleum products. Its three refineries account for one third of Spain’s total refining capacity.

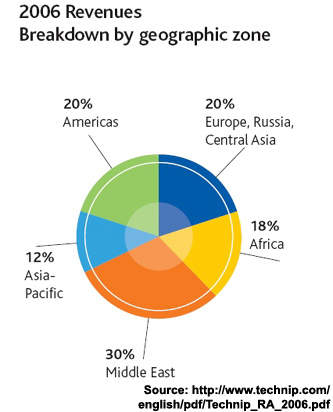

Additionally, the company has a petrochemicals business, manufacturing intermediates for a wide variety of products used in the food, pharmaceutical, chemical, plastic and textile industries. Cepsa is also involved in other energy-related activities, such as oil and gas exploration and production, and is rapidly broadening its presence in the natural gas and power sectors. It has an expanding global portfolio of operations in countries such as Algeria, Brazil, Canada, Colombia, Egypt, Panama and Portugal.