The Shidao Bay nuclear power plant (NPP), also known as Shidaowan NPP, is being built in Ningjinwan north of Shidao Bay, Shangdong province, China.

The NPP will be operated by Huaneng Shandong Shidao Bay Nuclear Power Company, which is a joint venture (JV) led by China Huaneng Group. The company’s partners in the JV include Tsinghua University and China Nuclear Engineering.

China Huaneng initiated preliminary work on a 200MW HTR-PM demonstration project for the NPP with China Nuclear Engineering and Tsinghua University in March 2004.

The project implementation plan was approved by the State Council of the People’s Republic of China, while the feasibility report was cleared in March 2011.

The project was delayed after the Fukushima NPP accident in Japan in March 2011. In December 2012, the HTR-PM demonstration project received the construction permit from the National Nuclear Safety Administration, marking the official start of construction with the pouring of the first concrete for the first unit.

NPP unit two and unit three construction with a 1,500MW capacity each started under the Shandong Shidao Bay CAP1400 demonstration project in 2019.

Shidao Bay nuclear power plant location

The NPP site is in the Ningjin Township area, Rongcheng city, Shangdong province. The HTR-PM demonstration project site is located approximately 68km to the south of Weihai city and 185km to the northeast of Qingdao city.

The project involves the construction of a concrete nuclear island and a conventional island.

HTR-PM nuclear reactor details

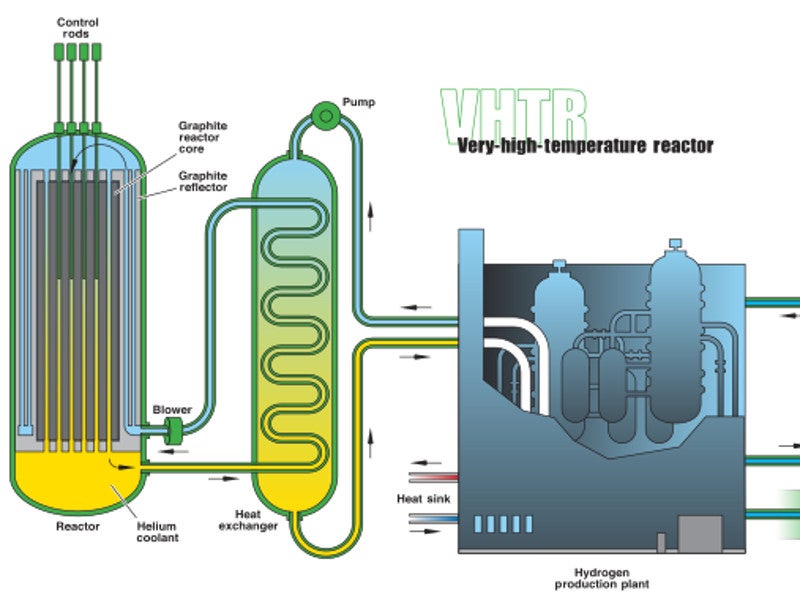

The high-temperature reactor pebble-bed module (HTR-PM) is a new generation modular high-temperature gas-cooled reactor (HTGR) with an outer diameter of 3m and a height of 11m. The reactor has inherent safety with fourth-generation safety features. China holds intellectual property rights for the HTGR technology.

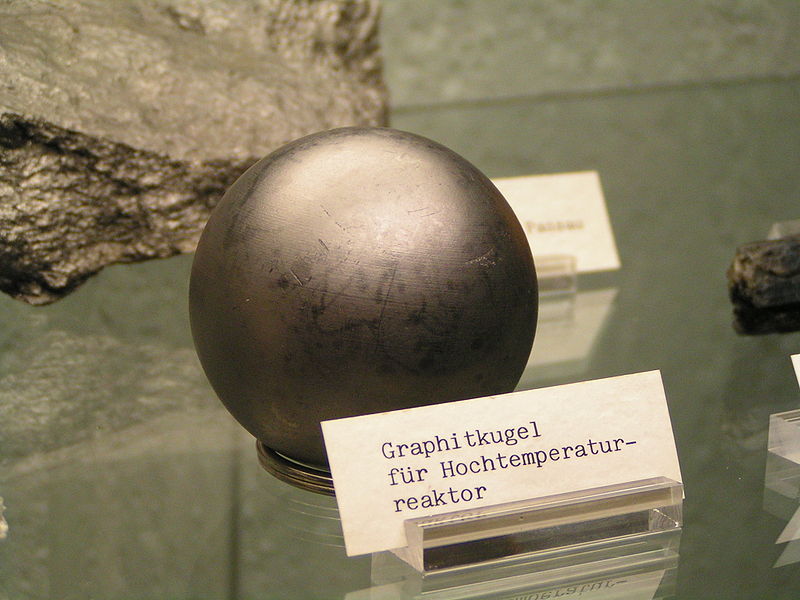

The Chinese-designed reactor uses tri-structural isotropic (TRISO) coated particle fuel, which is expected to ensure increased safety. The TRISO fuel design contains tiny uranium particles that are coated with layers of carbon and silicon carbide (SiC). The SiC layer can retain fission products below 1,600°C.

The reactor uses graphite as a moderator, while helium of low radioactivity level will serve as a coolant.

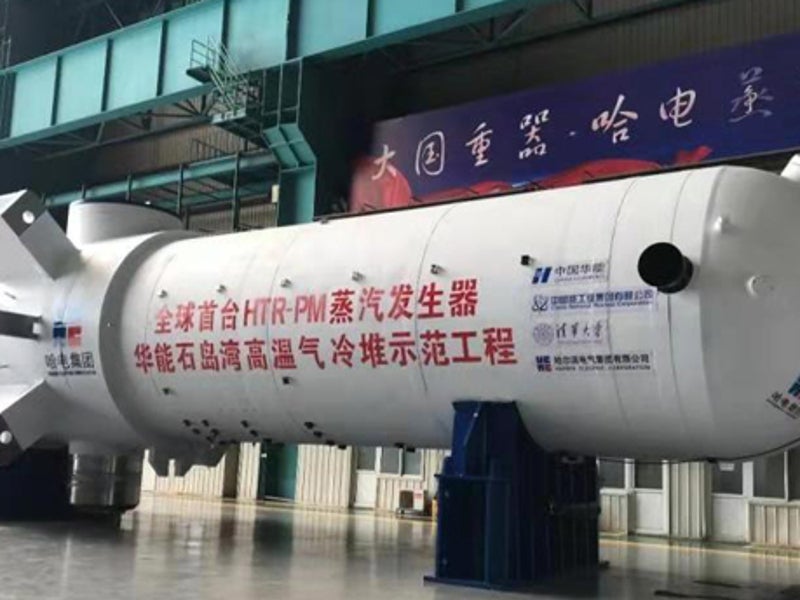

The HTR-PM demonstration project comprises two 250MW reactors and two steam generators. The reactors have individual primary loops and shared auxiliary facilities, including fuel handling and helium purification systems.

The reactors feature a single zone pebble-bed cylindrical core and independent control rod and absorption ball shutdown systems. The passive residual heat removal system improves reactor safety features.

CAP1400 nuclear reactor details

CAP1400 is a pressurised water reactor (PWR) with 1,500MW electric power. Based on the Westinghouse AP1000 design, the CAP 1400 nuclear power technology was independently developed by the State Nuclear Power Technology Corporation (SNPTC).

China’s National Energy Administration approved the reactor design in January 2014. The reactor passed a safety review by the National Nuclear Safety Administration in February 2016.

SNPTC incorporated feedback from the Fukushima power plant accident and designed the reactor with improved safety features and thermal safety margin of more than 15%. The steel containment vessel size was increased and the outer layer was strengthened to cope with large commercial aircraft impacts.

Shidao Bay nuclear power plant project contractors

Chinergy received an engineering, procurement and construction (EPC) contract for the nuclear island development. The company is also responsible for plant design.

Nuclear Industry Huaxing Construction and Nuclear Industry 23 Construction carried out nuclear plant civil installation together with China Nuclear E & C Group and China Engineering Group Zhejiang Thermal Power Construction.

SEPCO Electric Power Construction and Jiangsu Electric Power Construction conducted the civil installation of the conventional island.

Harbin Electric supplied steam generators. Toyo Tanso was responsible for supplying graphite. China General Nuclear Power Corporation (CGNPC) supplied the distributed control system (DCS) and simulator.

Shanghai Electric supplied several components, including metallic reactor internals, steam turbine, helium circulators and reactor pressure vessel (RPV). AS Schneider is also involved in the project development.