The 2,000MW Seoinchon combined-cycle plant located on the island of Ildo, 40 miles south east of Seoul, was ordered in 1994 to meet increasing summer peak demand in Seoul’s metropolitan area. The project expanded the already established 1,800MW combined-cycle plant to over 3,600MW. The project was officially finished in November 1997, before the restrictions on the state-owned utility for electricity Korea Electric Power Co (KEPCO) capital expenditure began to take effect. The expansion project made Seoinchon the largest combined-cycle plant in the world.

The Seoinchon project is broadly similar to the company’s Poryong plant. It includes four 500MW power trains, each made up of two gas turbines and a steam turbine. KEPCO aimed to secure high efficiency, low emissions, low capital costs and a short lead-time with the classic CCGT advantages. Total investment was an estimated $900 million.

Since going into operation, the facility has been demerged and the ownership restructured. Korea Western Power Inc. owns the 1,800MW plant and Korea Southern Power owns the 2,000MW plant. Both of these companies are subsidiaries of KEPCO.

PLANT MAKE-UP

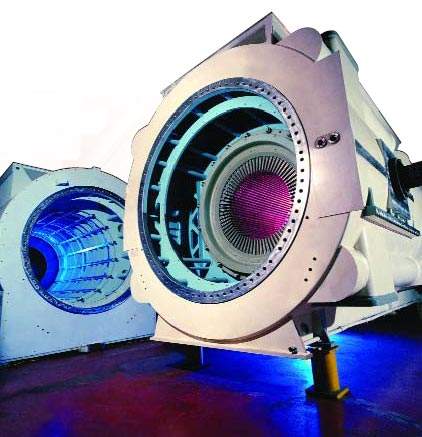

Korea Power Engineering Company (KOPEC) carried out plant design and engineering for the construction of Seoinchon combined cycle power trains. Building from its experience gained on coal-fired power plants, the company claims to have achieved full self-reliance in designing combined-cycle power plant. GE, with local partner Hanjung, secured the lead equipment supply order, worth around $500 million in October 1994. Its scope includes four STAG 207FA combined-cycle units. Each unit consists of two MS7001FA gas turbine generators and one steam turbine generator.

The GE 7FA machines installed at Korea Electric Power Corporation’s Seoinchon plant were the first gas turbines in the world to reach 55% gross thermal efficiency in combined-cycle operation. GE claims that this efficiency translates into cost savings for KEPCO. For each percentage point increase in thermal efficiency, GE states that an annual plant fuel cost saving of $6.4 million can be expected, based on fuel costs of $4.75/GJ for natural gas. This assumes each unit operates at full capacity (approx. for 6,000 hours per year), which will in fact not be true for the Seoinchon units.

These units produce 167.8MW when firing natural gas at ISO conditions. The F machines achieve their high operating efficiency by having a high firing temperature of 1,290°C. The high firing temperature uses first stage turbine buckets with a cooling arrangement based on GE’s CF-6 aircraft engine. The bucket cooling system includes leading-edge film cooling and uses a patented nickel alloy. The material is used on the stage one, two and three buckets on the 7FA and 9FA turbines. It is directionally solidified GTD-111, a nickel alloy with 14% chrome, 9.5% cobalt and 4.9% titanium, as well as tungsten, molybdenum, aluminium and 2.8% tantalum.

In December 2001 both of the plants decided to boost efficiency and profitability by introducing a software-based optimization system. GE was the chosen contractor for the job. Hanjung supplied the heat recovery steam generators and other auxiliary equipment. They were responsible for on-site construction and supplied construction materials and the balance of plant.

FUEL SUPPLY

Korea is heavily dependent on imported energy. The depreciation in the value of the Won led to increases in energy costs with a knock on effect on the growth of energy consumption. Korea Gas Corporation (KOGAS), a state-owned utility, scaled back purchases of liquefied natural gas from Abu Dhabi intended for KEPCO. KEPCO’s projected requirement of 5.56 million tonnes of LNG in 1998 was scaled down to just 4.2 million tonnes. Although LNG imports to South Korea fell by 9% in 1998, the economy subsequently recovered, growing by 24% in 1999, and totalling $37.65 billion in 2000.