Radiological supervision in nuclear operations has long relied on fragmented, site-specific tools that are difficult to scale, secure, and modernize. Mirion, a provider of radiation safety technologies to the nuclear sector, has sought to address this by using its Vital® Platform and Vital® Supervision application to enable consistent, real-time oversight of radiological instruments across complex sites.

By introducing a unified, web-based supervisory layer that can monitor thousands of instruments in real time, and by embedding nuclear-grade safety and cybersecurity principles into its design, Mirion has reshaped how radiological data is collected and analyzed, supporting safety and efficiency of nuclear sites. In recognition of this, the company has received dual honors in the 2025 Power Technology Excellence Awards, winning the Innovation award in the Supervisory Software category and the Safety award in the Nuclear Safety category.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Innovation in supervisory software for nuclear operations

The Vital Platform, with Vital Supervision as its first application, is presented as an innovative response to the complexity of managing radiological instrumentation across large and heterogeneous nuclear facilities. Instead of treating each radiation monitor, dosimeter, or fixed detector as a separate endpoint with its own interface and management tools, Mirion has created a common supervisory backbone that brings these elements together in a single web‑based environment. Supervisory systems have often been bespoke, tightly coupled to specific hardware, and challenging to evolve. By framing instrumentation oversight as a platform capability rather than a collection of point solutions, Vital provides a digital foundation that can absorb new devices and applications over time without forcing wholesale replacement of existing infrastructure.

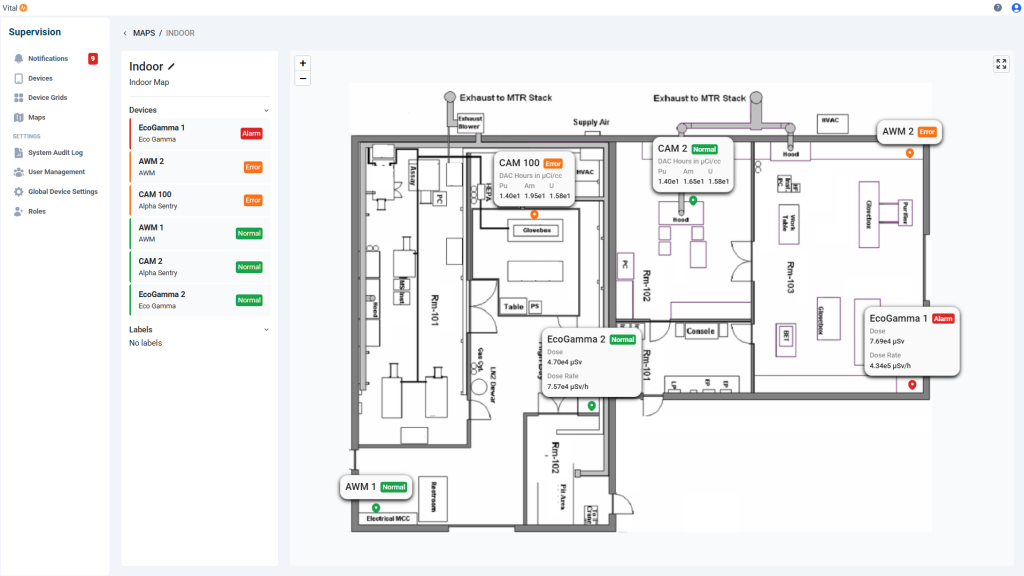

A key element of this approach is the way Vital Supervision combines real‑time operational views with analytical capability. Users can move fluidly from a high‑level map of a site, showing the location and status of instruments, to configurable device grids that track subsets of equipment by task, location, or permit. From there, they can access individual device detail screens that toggle between live readings and historical data. Because the platform incorporates a built‑in historian, the path from event detection to trend analysis is direct. The same interface that highlights an alarm also allows operators and engineers to reconstruct the sequence of measurements, instrument health indicators, and configuration changes that preceded it. This reduces the separation between “control room” displays and “engineering analysis” tools and makes post‑event review more accessible and consistent.

The platform’s modular design and scalability further support its innovative character. Built as a multi‑user, browser‑based system with support for 10,000+ instruments and sensors, Vital can be deployed as a desktop instance or as a site‑level server, with the current offering on‑premise, and cloud, or hybrid enabled by design. Instruments can be added, reconfigured, or removed on a live system without disrupting other devices, an approach that is important in nuclear environments where extended downtime for digital upgrades is both costly and operationally sensitive. Standardized communication parameters and tailored protocol handling shorten deployment and configuration times, enabling temporary and permanent systems to be stood up in minutes rather than in the days or weeks typical of traditional supervisory rollouts.

Vital has also been conceived as a host for Mirion’s broader digital ecosystem. The platform is not limited to a single class of monitors; it already supports a range of Mirion instruments, from personal dosimeters and survey meters to noble gas and particulate monitors, while explicitly allowing for additional devices and applications to be layered in as new requirements emerge. This platform strategy moves supervisory software from being an end‑of‑line integration task to being the main mechanism through which new radiological safety capabilities are introduced and scaled. In effect, Vital is designed as a central hub for radiation safety data across a site, positioning Mirion and its customers to sustain digital development without fragmenting their supervisory landscape.

Mirion’s innovation is not purely functional; it also involves harmonizing modern usability with the compliance demands of the nuclear sector. Vital’s role‑based access model, unified interface, and intuitive navigation are structured to reduce data noise and focus users on the instruments and workflows relevant to their roles, while comprehensive audit logging captures every material user action and configuration change. The result is supervisory software that advances usability and standardization while maintaining the traceability, repeatability, and documentation required for regulatory scrutiny. The platform, therefore, reflects an evolution in how digital infrastructure for radiation oversight is conceived, delivered, and maintained within nuclear operations.

Advancing nuclear safety through integrated, remote supervision

Traditionally, many routine tasks related to radiological instruments, such as modifying alarm setpoints, performing configuration changes, or checking state of health, have required personnel to enter controlled or higher‑dose areas. By enabling secure remote operation and oversight of a wide range of detectors and dosimetry devices, Vital Supervision directly reduces the need for such field entries. This supports the ALARA principle by helping to drive down cumulative dose from routine activities and ensuring workers are only sent into radiological environments when their physical presence is necessary.

The safety impact extends beyond dose reduction to the way the platform supports situational awareness. In outage work, emergency drills, or unplanned incidents, nuclear operators often must reconcile information from multiple systems to build a coherent view of site conditions. Vital consolidates these fragments into a single, near real‑time operational picture. Alarms, alerts, and fault conditions from diverse instruments are surfaced through a common notifications dashboard that clarifies event priority, duration, and origin. Coupled with map‑based visualization and customizable device grids, this gives radiation protection and operations teams a site‑wide view of radiological conditions and instrument status at a glance, enabling quicker, more targeted responses in time‑sensitive situations.

Safety in nuclear environments also depends on the reliability and integrity of monitoring chains themselves. Vital Supervision makes the health, calibration status, and communication state of instruments visible as a central concern rather than as background maintenance data. Its historian logs state‑of‑health indicators alongside measurement data, allowing operators to detect emerging anomalies before they become failures and to plan maintenance in a structured, risk‑informed way. By systematically highlighting devices that are drifting, offline, or overdue for calibration, the platform helps reduce the likelihood that a critical area is being monitored by an instrument that is malfunctioning or misconfigured, a scenario that can mask developing hazards or undermine confidence in emergency readings.

The system’s security model is also integral to its safety profile. Role‑based access control ensures that only appropriately authorized personnel can change instrument configurations or acknowledge and resolve events, while audit trails record who made which changes and when, including the before‑and‑after values of key parameters. This not only limits unsafe or unauthorized modifications but also allows organizations to reconstruct and analyze the human factors behind any deviation from expected practice. Over time, this evidence base can be used to refine procedures, adjust training, and strengthen defenses against inadvertent errors and inappropriate actions.

Cybersecurity is treated as a core part of nuclear safety in Vital’s design. The platform is developed in line with established nuclear cybersecurity guidance, including NEI 08‑09, relevant NIST standards, and 10 CFR 73.54. It supports generation of software bills of materials for transparent vulnerability assessment and employs code signing and automated security scans to maintain software integrity. For nuclear operators, this alignment means that efforts to protect people from radiation exposure are supported by protections in the digital systems that manage critical safety information. It also simplifies the process of demonstrating compliance with regulatory expectations around both physical and cyber protection of safety‑related systems.

Finally, Vital’s capacity to store and analyze historical exposure and instrument data supports continuous improvement in nuclear safety programs. By aggregating trends in alarms, doses, instrument faults, and response times, sites can identify recurring bottlenecks, procedural weaknesses, or training needs. This helps inform safety programs, updates to emergency preparedness strategies, and deployment of radiation protection resources during future outages and operational campaigns. In this way, the platform supports safe operations in real time and serves as a tool for structured learning and long‑term risk reduction.

“It is an honor to be recognized by Power Technology for excellence in innovation and safety for our Vital platform. Vital and the Vital Supervision application were created to give our customers a secure, integrated ecosystem that brings critical radiation safety data into one intuitive view, helping them act faster and with greater confidence. This award affirms the Mirion commitment to partnering with the nuclear industry to advance both operational efficiency and safety technologies to enable breakthrough innovations.”

– Shelia Webb, Chief Digital Officer, Mirion

Company Profile

Mirion is a global leader in radiation safety, science and medicine, empowering innovations that deliver vital protection while harnessing the transformative potential of ionizing radiation across nuclear, medical, defense, and research fields.

Mirion is a global company, headquartered in the United States (Atlanta, GA), employing approximately 3,200 people. Focused on nuclear and safety, the Mirion Technologies group is committed to powering advancements in nuclear energy through proven radiation safety technologies and expertise. Dedicated to driving better patient care, the Mirion Medical group is focused on improving quality in cancer diagnosis and treatment through its broad range of solutions that enhance the delivery and ensure safety across the medical landscape.

From securing borders and providing clean energy, to fueling space exploration and advancing precision medicine, there is essential and inspiring work being done by the customers we serve. At Mirion, we take great pride in these partnerships.

Contact Details

Erin Schesny

Links

Website: https://www.mirion.com/

Vital Platform: https://www.mirion.com/solutions/the-vital-platform