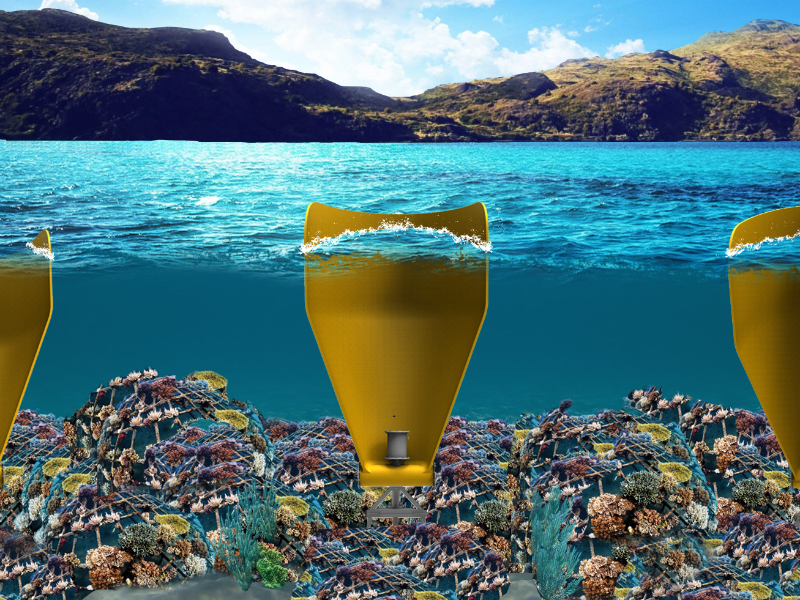

British wave energy start-up Zyba has teamed up with Biorock, which builds artificial coral reefs with the hope of simultaneously providing energy and coastal protection for islands. It has developed a new curved technology, the CCell, with a lightweight design that allows it to capture a greater amount of the ocean’s awesome power than its competitors.

Working with Biorock – both the company and technology name – Zyba hopes to provide island communities with a new source of clean and reliable energy. The power will also be used in the construction of coral reefs, which provide important coastal protection and bustling ecosystems for marine wildlife.

Hidden among the reefs, the CCells will take advantage of the total theoretical global wave energy potential of 32 petawatt (PW) hours per year. So far, no large-scale application for wave technologies has been successful and so Zyba is championing a smaller-scale approach. The power it creates is designed to enter the grid network and work alongside other renewable sources.

Symmetric vs asymmetric wave energy devices

The concept of the CCell arose from the company’s founder, William Bateman, asking a simple question: “The energy in the ocean leads from the open ocean towards the shore, so it’s an asymmetric problem,” he says. “All I fundamentally did was question why are people making symmetric devices.

“I never meant to start a business in wave energy but I was looking at their devices and they were all symmetric, so they were either round or they were flat.”

Bateman went to University College London in 2012, where he asked friends to test a curved panel against a flat one. The results came back vastly in favour of a curved panel, which moved 40% more than the flat one, based on wave motion. As testing continued, researchers showed that as the wave hits the face of the panel, the curved shape forces the energy towards the central core where it could be collected. Additionally, the shoreward face of the panel is subject to less stress than a flat panel because the convex shape cuts through the water smoothly, reducing the risk of the panel becoming damaged in rough weather.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataFrom this point, the project snowballed into Zyba and the patented CCell technology. With prototypes and testing complete, the final CCell was made comprising a glass and carbon fibre composite, making it light, flexible and, importantly, corrosion-resistant to increase its lifespan in seawater. There is only one moving part in each of the modular units and it has the highest known power-to-weight ratio of any wave device.

A symbiotic relationship protecting reefs

Zyba aims to tackle energy problems that large sources, such as offshore wind, cannot. “We have really moved away from using wave power for grid-scale electricity generation in the short term, but instead really trying to carve out a niche where wave energy is unique and actually has a significant intrinsic benefit,” says Bateman. “That’s really come about in the last six to nine months. Our focus at the moment has really been on coastal protection using a combination of the CCells and our partner’s technology, which is called Biorock.”

Biorock has been developed over the last 30 years by Professor Wolf Hilbertz, who died in 2007, and Dr Tom Goreau, as a way to grow artificial concrete. Biorock uses electrolysis to create a limescale-like substance by attracting the minerals in seawater. The rock this creates grows incredibly fast, as much as several centimetres a year, and is incredibly strong.

“The biggest single challenge for Biorock has always been its thirst for power at sea, conversely, we’re coming into a market where we are generating this power at sea and we need to get it to shore,” explains Bateman.

The companies have thus formed a partnership that allows them to build artificial concrete that protects coastal areas, while bringing in revenue from renewable energy production. “By collaborating with Biorock we are developing a symbiotic relationship in which we provide them with the power that they need,” says Bateman. “Equally, we can position our device where Biorock is growing a reef, so they are providing protection and fundamentally mass which helps to keep our unit in position.”

Clean and cool energy, despite challenges

As a start-up, Zyba’s main challenge throughout development has been financing. “For a physical product, where you have to do lab testing or actually offshore deployments, the costs are relatively high,” says Bateman. “When you’re doing the research and testing, you don’t really have time to be applying for funding, and then you get to the end of one round of funding and you have to stop and think, where am I getting the next bit? Obviously, you try to overlap them but often the funding doesn’t overlap so you do spend a lot of time and concern on how to grow in a sensible way.”

However, increased recognition for the technology over the past year has led to greater opportunities. Zyba was chosen to be part of the Clean+Cool Mission, organised by Long Run Works and sponsored by Innovate UK and the Department of International Trade it connects start-ups with investors in Silicon Valley, California, and allows entrepreneurs to share and develop ideas.

“Earlier this year we were selected alongside a group of 19 other companies to represent the greatest and the best of UK clean tech,” says Bateman. “It’s really interesting talking to the people over there because their attitude to start-ups is very, very different to what we see in the UK. It’s almost like everyone has a start-up, everyone’s got something going on in their garage and it’s all very chaotic.”

The trip encouraged the Zyba team to work on making changes in big increments by targeting smaller savings, leading to a focus on the nitty-gritty of the supply chain. “We originally thought that we’d manufacture the devices in the UK because the tooling behind the construction of our composite paddles was one of the major costs,” says Bateman. “Over the last six months we’ve actually been able to drive down the cost of our tooling for our relatively small device, from about £50,000 down to almost £2,500. The cheaper tooling is actually a better product – it’s a better module than the one we’d been quoted £50,000 for.”

Following Clean+Cool, Zyba decided to ship flat pack paddle moulds instead of the paddles themselves. It will provide local craftsmen, particularly yacht builders who are used to the required composite materials and methods, with the moulds and tools to make the CCell close to where it will be installed. This will help reduce the cost of the CCell, as well as supporting local communities.

Connecting wave energy to the grid

Zyba hopes the first CCell will be running offshore next year. “We are working really hard to get a row of devices installed just off the coast of Mexico,” says Bateman. “Hopefully by January, at the latest March, next year, it’ll be installed. What’s constraining us at the moment is overcoming some of the regulatory hurdles.”

CCells will be positioned along the coast of the island of Cozumel, starting with just one module. “The vision is that you would install one just to start with, just to make sure that you understand the local conditions and everything is correct, and then in the following years install in a line of devices along the shore,” explains Bateman.

Energy will then be transported underground to the island, where it will enter the grid system and work alongside other power sources. “Give or take 10%-20% of the energy that we generate will be needed to grow the Biorock, and the rest of that power we can then provide as an export to shore,” says Bateman.

The CCell could help provide clean, renewable power for small island communities, while protecting the coast and the underwater environment from the ocean. It’s a technology that kills two birds with one stone, and showcases a lot of potential on a small scale.