The global energy sector is undergoing a profound transformation. As it does, plant owners face a daunting challenge: adapt rapidly, or risk irrelevance.

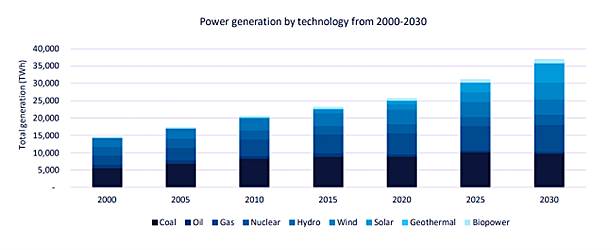

Undoubtedly one of the major drivers is the rising share of renewables as a proportion of total power generated. Although countries are at different stages in their energy transition journey, GlobalData figures suggest renewable energy will account for over 40% of global electricity generation by 2030. Substantial growth in solar photovoltaic (PV) and wind power will be the key drivers.

Solar PV alone is projected to contribute approximately 15% to the global electricity generation mix by 2030, with wind power close behind at 13%. Hydropower, historically a dominant renewable resource, is expected to drop to third place with around 12%. Significant investments in renewable infrastructure are accelerating change in even the largest markets.

Another challenge is rising demand. Consider the growth of data centres, the powerhouses of the AI-revolution. According to GlobalData estimates, the worldwide data centre and hosting market was valued at nearly $107 billion in 2023, and will grow at a compound annual growth rate (CAGR) of 8.75% to reach over $162 billion by 2028. Across all economies, sectors are digitizing and data is the lifeblood enabling them to do so; power plants need to crack down on potential intermittency now to guarantee it continues flowing.

As a result of all this, plants are facing pressures to improve their position on the dispatch curve. The most efficient power plants – those that can generate the most electricity at the lowest cost – are more likely to be dispatched, meaning they are used to meet electricity demand. Those that fail to do so risk obsolescence. The flexibility to ramp up and down has become an indispensable attribute of modern generators.

As the world moves through the energy transition and demand for electricity continues to evolve, the need for reliable, flexible, and secure electricity generation becomes more pressing – but also harder to satiate. Despite record growth in renewables, gas still supplies around 25% of the world’s electricity. It also plays a crucial role in stabilizing grids and filling in gaps when renewable output dips. New solutions are needed.

Adapting to Change: Siemens Energy’s ATEP

Bringing plants into the 21st century is essential. Enhancing performance improvement in gas turbines will ensure energy security as the transition towards a more sustainable system speeds up. But how can gas plant owners modernize and futureproof themselves against the backdrop of a changing industry? The Advanced Turbine Efficiency Packages (ATEP) from Siemens Energy can help. Utilizing state-of-the-art turbine technology initially developed for Siemens’ HL-class gas turbines, ATEP upgrades employ advanced aerodynamic designs that optimize airflow, reduce cooling air requirements and elevate turbine pressure ratios.

Gas turbines are essential for reliable backup. But ATEP innovations also translate into massive performance improvements. An ATEP upgrade can provide increases in combined cycle efficiency worth up to two percentage points compared with previous offerings, and an additional plant power output of >10% per plant. This translates into lower emissions per megawatt-hour, directly contributing towards meeting environmental targets. And ATEP blades are hydrogen-ready, providing flexibility to transition to hydrogen-based fuels later on.

Recent projects reflect the ATEP’s potential where it is rolled out. The implementation by PacificLight Power (PLP) at their 800 MW plant on Jurong Island, Singapore, is a prime example. The facility, the first in the region to utilize ATEP technology, is powered by 2x SGT5-4000F, providing approximately 10% of Singapore’s electricity. The upgrade led to efficiencies surpassing 60% – a first for any power plant in Singapore – combined with an increase in power output of 30 MW.

The upgrade reduced annual carbon emissions by over 60,000 tons, equivalent to removing more than 9,300 cars from Singapore’s roads each year. Such enhancements have placed PLP at the forefront of efficiency and environmental performance in the region. Additionally, upgraded turbines can support increased flexibility. With these turbines able to ramp up and down at a rate of 50MW per minute, wider operational ranges are brought well within reach for the plants using them – making lower loads possible within prescribed emission levels. Altogether, it reinforces the economic and environmental case for modernizing existing infrastructure rather than replacing it – and provides a template for plants confronting the need to modernize.

Trailblazing Solutions from Expert Partners

More and more, industry leaders are showing how gas-fired power plants can be adapted to handle new operational realities. And they can offer comprehensive solutions tailored to individual market needs. Recognizing the enduring role of gas turbines in grid stability, Siemens Energy provides an outstanding example: the company offers advanced operational enhancements, predictive maintenance technologies, battery storage integration and progressive hydrogen compatibility upgrades.

Their Flex-Power Services™ products are a boon for operational flexibility. These can reduce start-up and shutdown times by as much as 50%, temporarily increase maximum power output, and optimize load gradients to address renewable intermittency. This can be assisted by digital tools, such as Siemens Energy’s Omnivise Asset Performance Management, which enhances plant reliability by enabling proactive maintenance and condition-based maintenance planning.

Additionally, Siemens Energy supports owners in the process of transitioning their power plants to residual load coverage or seasonal operation. Their innovative Battery Energy Storage Systems (BESS) installations can leverage existing grid infrastructure, reducing overall investment costs and improving average plant efficiency by enabling operations at optimal load ranges during lower demand periods. In the longer term, with hydrogen poised to play a pivotal role in energy storage and decarbonization strategies, Siemens Energy is laying the groundwork by actively increasing the hydrogen readiness of its turbines. In doing so, they are aiding plant operators in meeting stringent environmental standards today while futureproofing their investments for tomorrow.

Siemens Energy also offers a range of innovative retrofit and maintenance programs. These include the Rotor Exchange program (ROTEX), enhancing the reliability and operational lifespan of aging assets – crucial in maintaining high operational standards. The program can have many benefits depending on the project for which it is deployed. One is saving outage time, especially during major upgrades where may modifications need to be implemented, helping to keep costs minimal. The approach is one that can reduce risks associated with onsite work, and can significantly simplify maintenance.

Since 2010, switching from coal to gas has saved around 500 million tons of CO2 – equivalent to putting 200 million zero-emission EVs on the road. Companies like Siemens Energy are at the forefront of this effort, with around 16% of global power generation based on their technology. As the world faces rising energy demands and the complexities of a renewables-led grid, high-efficiency gas turbines will remain a vital, flexible tool to power the transition forward.

Through initiatives like the pioneering ATEP installations and global hydrogen co-firing trials, Siemens Energy highlights how existing infrastructure can be upgraded, modernized and made fit for the future. Since 2010, switching from coal to gas has saved around 500 million tons of CO2 – equivalent to putting 200 million zero-emission EVs on the road. Companies like Siemens Energy are at the forefront of this effort, with around 16% of global power generation now based on their technology. As the world faces rising energy demands and the complexities of a renewables-led grid, high-efficiency gas turbines will remain a vital, flexible tool to power the transition forward. Download the whitepaper on this page to learn more about Siemens Energy’s cutting-edge solutions and how they could help you upgrade your turbines today.