For years, ethanol has been a big carrot on a short string. Offering to solve the planet’s energy problems, bring jobs and create new industries around farming, ethanol seems like an ideal replacement for petrol (gasoline).

It burns cleanly with a high-octane value, can often be grown locally from renewable sources, decreases the amount of expensive crude oil needed to produce fuel and reduces harmful auto emissions. It is also cheaper than petrol and as a bonus is biodegradable.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Following ethanol’s leap into production in the US, where it has taken off as an important fuel source, many other countries are considering a future based on ethanol.

However, there are still question marks over its use as a truly ‘environmentally friendly’ fuel. As with the implementation of many other ‘green’ initiatives, it leaves a number of resulting social and (displaced) environmental effects.

ETHANOL – A BREAK DOWN

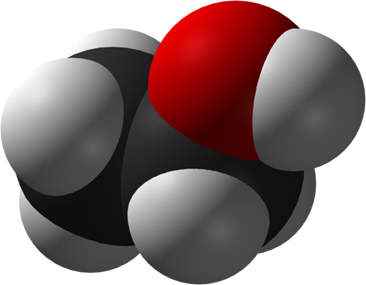

Ethanol (CH3CH2OH) is also known as ethyl alcohol or grain alcohol, with the hydroxyl (-OH) group making it an alcohol. Ethanol is 35% by weight oxygen – the highest proportion of any available fuel. It burns more completely and more cleanly than petrol, cutting vehicle emissions of CO, NOx, particulates and ozone-forming pollutants. The liquid has a freezing point of –114.1°C, making it suitable for use in anti-freeze products, and a boiling point of 78.5°C.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataEthanol can be produced from petrochemicals by hydrating ethylene, or by fermenting the sugars found in plants. Corn is the main feedstock, supplying a fairly low-cost source of starch that can easily be converted into sugar.

Ethanol can also be made from other cereal crops such as wheat, rice, maize, barley and pearl millet as well as sugar itself, or from cellulosic materials. These include sorghum, switchgrass and other grasses, along with wood and waste products.

However, fairly little research has been undertaken on the comparative energy and greenhouse gas emission reductions from the different feedstocks. The research that has been carried out also largely fails to consider what the land would otherwise be used for. Cellulosic materials have lower yields, for example, but can generally be grown on marginal agricultural land, and require less fertiliser and water.

Canadian environmental management consultancy Envirochem Services says crops such as switchgrass have a much higher yield per acre. Switchgrass is fast growing and contains enormous amounts of sugar. It can yield over 1,000gal per acre (about 1,500l per hectare): more than three times the yield of corn. However, monoculture switchgrass may not be the answer where it is a non-native plant.

Native species of fast-growing trees may well be the best overall long-term solution. Willow ethanol, for example, promises to be as near as possible to a CO2 neutral liquid fuel. It is perennial and stores large amounts of carbon in its large root system and even restores soil organic matter. It can also be burned instead of coal to fuel the ethanol production process itself.

The processes required to make ethanol also need large amounts of energy, largely due to the distillation process. Other environmental implications include energy consumption and related emissions from farming, fertiliser use, transport, drying, processing and storage.

For wheat and corn, all this can take up almost half of the total biomass energy, although this still leads to reduced greenhouse gas emissions because the biofuels are displacing fossil fuels.

US ETHANOL USE

The US, however, views ethanol as an extra economic engine, adding value to agricultural products and bringing billions of dollars a year to its economy. Ethanol is produced at more than 100 plants there (mostly in the Midwest) and then blended into unleaded petrol in varying percentages. Because it is domestically produced, ethanol will help the US in its important search to reduce its dependence upon foreign energy sources.

Pure, 100% ethanol is not normally used as a motor fuel; a percentage is instead combined with unleaded petrol. Besides decreasing petrol costs, this increases the fuel’s octane (anti-knock) rating and decreases harmful emissions. In the US, ethanol is most commonly sold as E10, a 10% ethanol blend for use in automobiles.

E10 is approved for use in all vehicle makes and models sold in the US, without engine modifications. Nearly half of all petrol sold in the US contains some ethanol, mainly as E10. Many manufacturers recommend it because of its high performance and clean burning. Ethanol’s BTU value is lower than that of petrol, so it burns at a cooler temperature and causes less engine wear.

ACE (American Coalition for Ethanol) and others are researching the use of ethanol blends above 10% (E20, E30 and E40) for standard vehicles. This could dramatically increase the use of renewable fuels and decrease petroleum consumption.

Ethanol is also increasingly being sold in even higher concentrations, as E85 (an 85% blend) for use in Flexible Fuel Vehicles FFVs.

E85 can already be used in FFVs, with over six million on America’s roads today and rising. E85 fuel pumps are being installed across the US.

The blend can sometimes even be used in standard vehicles, with a non flex-fuel 2001 Chevrolet Tahoe having been run above 160,000km almost exclusively on E85. This vehicle is now being examined for effects on engine components.

However, most vehicles cannot use E85 since ethanol corrodes rubber, steel and aluminum, so FFV components are made of stainless steel. Fuel economy is lower, too, and vehicles also normally have to use 1.4gal (5.3l) of E85 for each gallon of petrol it replaces.

THE AMERICAN DREAM

The US imports nearly 70% of its oil, leading to a $100bn deficit in 2002. US ethanol production is now above 5.5 billion gallons/year (21 billion litres/year) and rising towards 6 billion gallons. That directly displaces crude oil to reduce the US crude oil trade deficit. Ethanol demand exceeds supply by over 10%, so over 650 million gallons/year (2,460 million litres/year) are imported from Brazil.

In 1997, Northwestern University’s Kellogg School of Management in the US produced a study on The Economic Impact of the Demand for Ethanol. It found that plants can create up to 4,000 local jobs during operation, with between $50m and $100m in extra yearly income for the local area.

The industry has also increased demand for corn which, in turn, has driven up corn prices. About 40% of the US ethanol production capacity is now owned by farmer cooperatives and other local investors. In recent times, certain developments have altered this balance of ownership.

FARMING A NEW INDUSTRY

Although local farmers initially benefited from increasing corn prices, they are now starting to wonder whether ethanol will be altogether a benefit. Cooperative ownership of production plants has given even small farmers a voice, but the ethanol boom has attracted the big players to the industry. They are squeezing out the farmers at the bottom – the very ‘local empowerment’ that is one of the great attractions of the fuel. New plants are backed by worldwide corporate investment and are dwarfing the farmer co-ops.

Some farmers have reported a doubling of fertiliser prices in just a few months and land speculation is driving prices beyond the ordinary farmer. Most US farmers rent all or part of their acreage, and rents are likely to increase in line with these price increases. Some are describing an ethanol ‘frenzy’, with reports of new landowners ripping out windbreaks and tree stands.

Some farmers are plowing up alfalfa fields, an excellent low-input low-maintenance crop that needs very little fertiliser or herbicide. That will affect the supply of locally grown alfalfa hay to dairy farmers. New ethanol plants can also require over 2 million gallons (7.6 million litres) of water a day in areas that are experiencing growing water shortages.

Corn is grown in the centre of the US and petrol is used on the coasts, so transportation costs can be over $1 per gallon: double the costs of petrol. It cannot be transported using established pipelines and tanks since it is corrosive and as an alcohol readily absorbs water and chemicals.

ETHANOL – THE WIDER IMPLICATIONS

Problems are also being reported outside the US. After the US, Brazil is the world’s largest ethanol producer. Brazil produces ethanol using sugarcane, which generates almost twice as much ethanol from the same land area as corn, at almost half the cost.

Production costs are around $1 a gallon for sugarcane but the US imposes a 54 cent per gallon tariff to block Brazilian imports.

Although this conflicts with US demands for ‘free trade’ elsewhere in the world, it may not be a bad thing. Brazilian rainforests are being cleared so farmers can plant corn, as well as soy beans to replace the US soy land that has been turned over to corn production.

That negates another major benefit of the fuel – that it is largely ‘carbon neutral because not derived from fossil fuels’.

Yet another problem is the effect on global grain production. This is already falling short of demand as food demand continues to rise. The question is whether we should be growing crops just to burn them again afterwards. Using corn places land for ethanol production in direct competition with agricultural land.

Ethanol is never going to solve all of the world’s energy problems – that is one thing that is known for certain. Even using all the accommodating land to produce its crops, it still could not produce everything that is required of life in 2007.

Biofuels can, undoubtedly, offer a chance to solve some of the planet’s transport problems. But unless production is sustainable, and unless it uses marginal land instead of prime crop land, we will just be exchanging one set of problems for another.