Genesis Energy has completed the new combined cycle gas turbine at its Huntly facility. Known as e3p (Energy Efficiency Enhancement Project), the plant was switched on two months early, in February 2007, and has now been commissioned. The $520m plant has a conversion efficiency of 56% compared with 37% for the existing Huntly power station.

The gas turbine burns natural gas, with a heat recovery boiler and steam turbine to generate 385MW – enough electricity for around 400,000 households.

The gas and steam turbines came from Mitsubishi Heavy Industries (MHI), and the HRSG is made by Downer Engineering Power Limited. The new turbines add to a 1,000MW coal and gas-fired steam plant, and a 50MW open cycle gas turbine generator already at the site. The natural gas comes from the on- and off-shore gas fields of Taranaki.

DRY LOW-NOx COMBUSTOR

Turbines are rotating machines that use fluids (typically air, wind, water or steam) to produce work. Combined cycle gas turbines combine two power cycles; the Brayton cycle (gas turbine) and the Rankin cycle (steam turbine).

The name ‘gas turbine’ is somewhat misleading, because it implies the turbine uses gas as its fuel. Actually, a gas turbine has a compressor to draw in and compress the gas (most usually air); a combustor (or burner) to burn the natural gas which heats the compressed air; and a turbine to extract power from the hot air flow.

The e3p gas turbine is a Mitsubishi M701F. It uses an inlet air-conditioning system, multi-stage air compressor, fuel supply and burner arrangement, gas turbine (expansion) and outlet exhaust gas system.

Air is compressed at a ratio of 17:1 before entering the dry low-NOx combustion system, where natural gas is fired to drive a combustion turbine with an inlet temperature of around 1,350°C. The hot gas then expands over four rows of rotating and stationary blades in the turbine section before exhausting into an HRSG at around 600°C.

HRSG AND STEAM TURBINE RAISE OVERALL EFFICIENCY

The Heat Recovery Steam Generator (HRSG) links the gas and steam turbines. Heat from the gas turbine exhaust generates steam by passing it through a labyrinth of water-filled finned tubes. The Downer Engineering HRSG is a horizontal gas flow, natural circulation type. It produces steam at three separate pressure levels: high pressure (HP), intermediate pressure (IP) and low pressure (LP) for use in each pressure section of the turbine.

Steam from the HRSG runs through a multi-stage turbine to spin an output shaft that drives the plant’s generator. The Mitsubishi Heavy Industries (MHI) steam turbine is a two-cylinder, condensing reheat

type consisting of HP turbine, IP turbine combined into one cylinder, and LP turbine.

HP steam is delivered from the HRSG at 104 bar (104 x 105 Pa) and 538°C for expansion in the HP turbine. Exhausted steam is returned to the HRSG where it is combined with the IP steam circuit before being reheated. The reheated steam is delivered to the IP turbine at 35 bar (35 x 105 Pa) and 566°C for expansion. Steam exhausted from the IP turbine is combined with LP steam for induction into the LP turbine at 6 bar (6 x 105 Pa) and 250°C. Steam expanded in the LP turbine is exhausted into an ‘under-slung’ condenser beneath the steam turbine for condensing.

HYBRID WET-DRY COOLING TOWER

Hot water from the steam turbine condenser is pumped to the top of the cooling tower and flows down through plastic partitions to produce water droplets. These are cooled by an upwards current of air and fall into a basin at the base of the tower. The water then flows back into the steam condenser to serve as a coolant once more.

A wet-dry (hybrid) type cooling tower accepts the steam turbine condensate. The cooling tower uses plume abatement to reduce plume levels and local ground fogging during adverse ambient conditions.

ACCESS ROUTE UPGRADED TO BEAR LOADS

Genesis Energy upgraded and reinforced the access route to transport over-weight and over-dimensioned components, including the Tainui Bridge in Huntly to increase the load-bearing capacity to 500,000kg (500t). Mitsubishi Heavy Industries made the turbine components at its Nagasaki and Takasago works, and at Mitsubishi Electric (MELCO) in Kobe.

Genesis Energy and Mitsubishi Corporation entered into a 12-year Long-Term Maintenance Agreement (LTMA) for the power train. Mitsubishi Corporation is responsible for carrying out planned and unplanned maintenance of the gas turbine, steam turbine, generator, and integrated control and monitoring system.

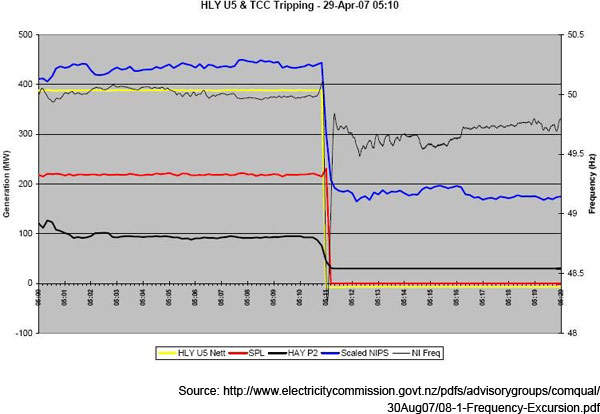

HUNTLY UNIT 5 AND TARANAKI TRIPPED OUT

There was a frequency excursion on 29 April 2007 in which both Huntly Unit 5 and the Taranaki CCGT tripped. Taranaki appears to have tripped about six seconds after Huntly Unit 5 with system frequency already around 49.2Hz at the time of tripping. Luckily, there was sufficient reserve response to avoid the operation of AUFLS.

The delivery of over 480MW of fast reserves in response to the event prevented the system frequency falling below 48.0Hz. The secondary tripping of TCC resulted from a lack of coordination between generation control systems and protection systems.