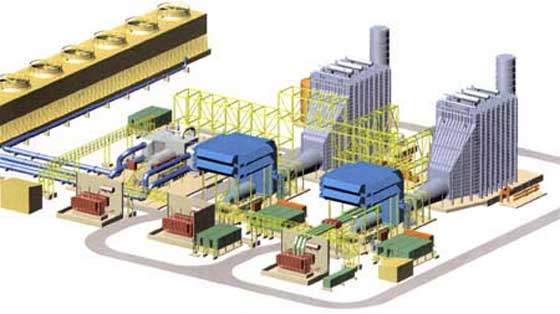

The AES Ironwood combined-cycle gas turbine (CCGT) plant has an output of 720MW. Located in Lebanon (near Harrisberg), Pennsylvania, US, it was one of the first to use Siemens Westinghouse’s 235MW W501G gas turbines.

The plant’s main fuel is natural gas. It also has a dual-fuel capability to burn distillate oil.

In 1998, the plant was ordered and construction began in June 1999. It started commercial operation on 31 December 2001. The plant has a 720MW output.

The owner of the plant is AES Corporation through its subsidiary AES Ironwood Inc.

The plant is an addition to the string of generating capacity that AES has built up in North and South America over the past few years, following the deregulation of these markets.

AES Ironwood CCGT power plant details

Siemens Westinghouse was awarded an equipment, procurement and construction (EPC) contract to build the plant. The contract’s estimated value is more than $280m. Siemens Westinghouse supplied two 235MW W501G gas turbines, a 230MW steam turbine and associated equipment. Siemens Westinghouse signed an eight-year maintenance agreement.

The heat steam recovery generators (HSRGs) were ordered by Siemens Westinghouse from Hanjung of South Korea. The contract was signed in February 1999. The equipment will be manufactured at the supplier’s Changwon plant in South Korea and delivered by December 1999. Hanjung is also supplying heat recovery steam generators to Siemens-constructed plants in Brazil and South Korea.

The order for HRSGs was a major victory for Hanjung, which had not won an order in the US since the late 1970s. Just a few months earlier, Hanjung won its first Latin American order of two HRSGs for the Cuiaba 500MW CCGT plant in Brazil.

Turbines

The turbine was a relatively new development of Siemens Westinghouse’s traditional range, and Ironwood was an early recipient of the new type (the first is in commercial production at a plant in Florida).

The W501G, a highly efficient 60Hz combustion turbine, incorporates the traditional design elements of the company’s W501 series, including a two-bearing rotor, axial exhaust, cold-end drive, and individual combustors.

In addition to the standard features of the equipment, Ironwood includes dry, low-NOx-emission combustion technologies to meet emission limits without water or steam injection when fuelled by natural gas. Most of the equipment was made in the US.

The W501G is an uprated version of the 501G gas turbine. The rotor inlet temperature is 1,417°C, the airflow is 544kg, and the pressure ratio is 19:1. The turbine has 16 compressor stages and four turbine stages. It has six cooled rows and an exhaust temperature of 593°C. This is a higher pressure ratio and firing temperature than Siemens Westinghouse’s 501F turbine.

Project finance

The plant was funded by a $308.5m non-recourse bond financing. The sale of bonds was primarily managed by Lehman Brothers and co-managed by Morgan Stanley Dean Witter and Dresdner Kleinwort Benson.

Williams Energy Marketing and Trading Company, a subsidiary of The Williams Companies, was selling the electricity and associated energy under a 20-year tolling agreement, but in November 2007 Williams closed the sale of substantially all of its power assets to Bear Energy LP, a subsidiary of the Bear Stearns Companies Inc. This transaction included the Pennsylvanian plant.