French utility EDF is building the world’s largest European pressurised reactor in Flamanville, France. Supplying 1,750MW, Alstom’s steam turbine is the largest ever for a reactor. The company is supplying the complete turbine island in an order worth more than €350m.

Alstom will carry out the engineering, procurement, construction and commissioning. It will supply all the major turbine island components.

ALSTOM SUPPLIES TURBINE ISLAND

The turbine island comprises the steam turbine, the generator, the condenser, the moisture separator reheaters and auxiliary equipment needed to convert steam produced at the nuclear reactor into electrical energy. Alstom’s 1,750MW Arabelle steam turbine was developed from its 1,550MW model.

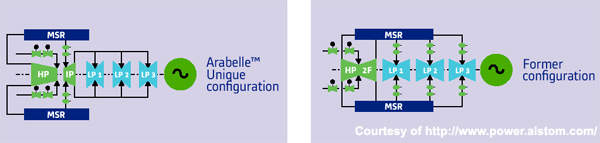

The design has a number of features to improve efficiency and reduce installation and maintenance costs. The architecture features a combined HP/IP casing using the impulse technique.

Highly efficient single-flow steam expansion is used between the HP inlet and the IP exhaust, producing more than 900MW on a 13-wheel rotor which is only 120t in weight.

Arabelle is also shorter and lighter than the nuclear steam turbines of the former generations. It can be assembled more easily as its LP modules have independent structures; the LP inner casing is independent from the LP exhaust hood and both are connected by flexible annular rubber joints.

This allows the LP turbines to be assembled independently of the condenser and facilitates the shaft-line alignment and corrections, which can then be carried out without the upper LP exhaust hood being

opened.

The position of the moisture separators/reheaters between the HP and IP steam expansions reduces the number of reheat valves. The MSR location on either side of the HP/IP casing provides large storage surface areas on both sides of the LP casings, making maintenance operations easier.

In addition, the IP-LP connecting ducts run under the pedestal (so-called ‘cross-under’ pipes), providing direct access to the LP modules since there is no need to dismantle the ducts to open the LP casings. It results in the erection and maintenance times being reduced by 15% and 20% respectively. The steam turbine has excellent mechanical behaviour, with fewer components (inlet valves, in particular), which is due to the design of the machine itself.

Commissioning tests for the 1,550MW model were conducted in the power stations of CHOOZ B2 and CIVAUX 1 (France), where less than one month elapsed between the reactor criticality and the first coupling of the machine. Four house load operations were conducted successfully on both units of CHOOZ B.

Alstom claims 2% higher efficiency than previous-generation steam turbines, hence a gain of around 30MW. The larger exhaust sections, made possible by the half speed rotation, allows Alstom to envisage even higher electrical outputs or lower condenser back-pressures. Arabelle can be adapted to either pressurised water or boiling water reactors.

WORLD’S LARGEST NUCLEAR POWER GENERATOR

Flamanville started commercial operation in 1985 with two 1,350MW units. The reactors are of the four-loop Areva ‘P4’ type. Under a number of separate contracts, Alstom designed, delivered and erected the turbine generators. It also supplied the bulk of the turbine island mechanical and electrical auxiliaries, including condensers, feedwater reheaters, and condensate extraction and circulating water pumps.

EDF is a major nuclear power generation company with 58 units in service, all of which use Alstom equipment in the turbine island. Arabelle turbine technology is installed in four 1,550MW units in the EDF nuclear power plants located in Chooz and Civaux, and is currently being installed in the extension of Ling Ao power plant in China.

The Flamanville turbine island will be designed to last for 60 years.