The Jorf Lasfar project expanded an existing coal-fired steam power station with two additional coal-fired 348MW units. This brings the total installed capacity to 1,356MW. The project involved the installation of two 348MW steam turbine generator sets, two coal-fired boilers, the control system, and a number of other pieces of equipment.

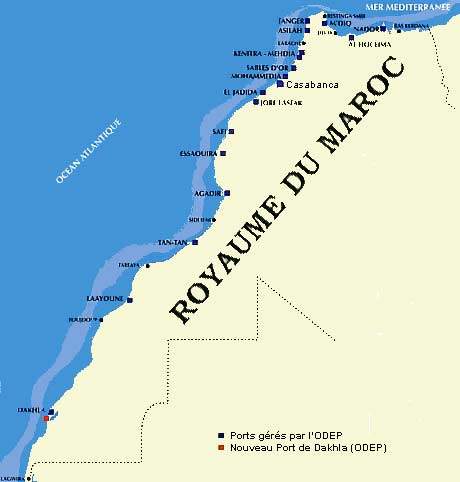

The Jorf Lasfar site is 130km south-west of Casablanca on the Atlantic coast in the El Jadida province. The coal-based power plant satisfies approximately 65% of Morocco’s base-load electricity demand and provides one-third of the country’s total electricity supply.

The $1.5 billion power plant is the largest independent power facility of its kind in Africa or the Middle East. A 30-year purchase agreement with the national power utility company, National de l’Electricité (ONE), provided a guarantee for a long-term buyer for the new electricity generated.

Jorf Lasfar power plant construction and financing

Power shortages and a population increase of 2.5% a year forced Morocco to seek definitive solutions to its growth problems. Demand for power increased by 7% a year, while 40% of the population was still without power service. The new plant was vital to the country’s economic development.

On 28 August 1997, the approval for the project was granted and construction began immediately afterwards. In October 2001, the final unit (four) started commercial operations at an estimated cost of $1.5 billion. 660MW units one and two were completed in 1994 and 1995 respectively. In June 2000, unit three was completed and it produces 348MW.

The project was developed as a private sector venture by a special purpose company, the Jorf Lasfar Energy Company (JLEC), under a build-transfer-operate arrangement, including the leasing of the existing units to JLEC to operate for thirty years through a Transfer of Possession Agreement with a transfer of possession fee. The same arrangement of transfer of possession and fee is applicable to the completed units. The accomplished objective of the Jorf Lasfar expansion project was to meet future demand for electricity in an economically and environmentally sustainable manner.

Securing financial support for the massive project proved to be a task, in which the two primary investors required assistance. While equity and reinvested cash from CMS and ABB totalled $585 million, a consortium of governmental, multilateral and private financial institutions provided the balance of $920 million. The US-based Overseas Private Investment Corporation (OPIC) issued a commercial guarantee for the project valued at $210 million.

Coal and fly ash

CMS and ABB will have the responsibility to handle four million tonnes of coal supply a year for Jorf and the government-owned Mohamedia power plant.

Prior to CMS taking over the plant in 1997, fly ash generated by the plant was pumped into the ocean. Since the first day of CMS operation, the plant placed all of the ash in a lined storage area. Since November 1999, Jorf has used a new long-term ash disposal site, which is located three miles from the plant and will last for 30 years of the plant’s operating life.

Jorf has was selling as much of its fly ash as possible to cement companies since July 1999. They received 30% of the ash monthly.

The plant was required stringent air quality standards put in place by the financial institutions funding the construction of units three and four.

Power plant contractors

According to the agreement, ABB built the units and CMS Energy subsidiary CMS Generation operates them. Thus, ABB is responsible for manufacturing the majority of the equipment such as the plant’s two 350MW steam turbine generator sets, two coal-fired boilers, the control system, and the balance of the plant’s equipment.