Construction is progressing on Southwest Power Station Unit 2 for City Utilities of Springfield, Southwest Missouri, US. The new Springfield pulverised coal-fired plant will add 300MW to the existing 195MW plant. The new unit will cost nearly $697.1m ($1.2bn including financing costs), and is reported to be on budget so far.

As of March 2010, 73% of the construction was completed. Unit 2 is expected to come on line in 2010. The project will add about 25 City Utilities jobs, and up to 640 workers on site during construction.

Project details

The existing installation has one boiler and two 52MW twin-pac turbine generators. Installed in 1976, the boiler can burn coal, pipeline grade natural gas and fuel oil number 2. An electrostatic precipitator and wet limestone scrubber control emissions. The twin-pac turbine generators (made in 1972 but not installed until 1982) can burn pipeline grade natural gas and fuel oil number 2.

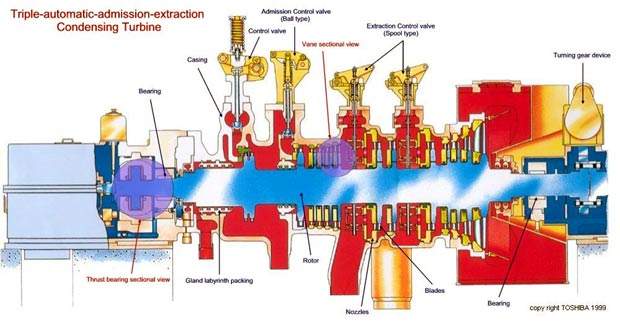

The new boiler island was assembled in China and the equipment was shipped in pieces to Springfield. The turbine generator was delivered by Toshiba in Japan, with turbine and generator costing $24.7m. During January 2009, turbine generator components started arriving along with the delivery of the generator.

Low-NOX burners with Selective Catalytic Reduction (SCR) will control the boiler’s NOX emissions. PM10 particulate emissions will be controlled using a bag-house, which will also help control inorganic hazardous air pollutants.

Dry Flue-Gas Desulphurisation FGD will control sulphur dioxide emissions, using lime as the reagent.

Good combustion practices will control carbon monoxide and Volatile Organic Compound (VOC) emissions.

Plant details

The new plant will make extensive use of digital bus-based technologies, with Emerson’s Ovation system incorporating 57 Foundation7#153; fieldbus segments (with 1,368 I/O) and 31 Profibus-DP segments (1,890 I/O) to network intelligent field instrumentation. In total, the Ovation system will manage nearly 4,200 I/O points.

Emerson will also install its AMS™ Suite: Intelligent Device Manager, which streamlines device configuration and commissioning for efficient plant startup. AMS Device Manager also provides online access to instrument and valve process data and predictive diagnostic information.

This gives valuable information that can optimise plant operations and maintenance activities, as well as help avoid costly unplanned outages. Equipment was delivered by March 2010. The unit will be commissioned in mid-2010 and is expected to be fully operational by the end of the year.

Emerson is also replacing existing ABB controls at Southwest Unit 1 with its Ovation expert control system. Unit 1 will also include a new selective catalytic reduction (SCR) system based on Foundation fieldbus technology. Equipment installation for Unit 1 was completed in 2008.

Will burn up to 170t/h

The boiler will burn up to 170t/h (over 150,000kg/h) of low-sulphur western sub-bituminous coal. Coal is already delivered to the Southwest Power Station using bottom dump railcars. Each train carries up to 18,000t (over 16,000,000kg) of coal, which is processed every 48 hours.

Coal is unloaded from the railcars into hoppers, to a transfer tower, stockout conveyor and storage pile. Conveyors will convey the coal from the storage pile to new in-plant storage silos and then to a new milling system.

A ‘dead’ storage pile will protect against interrupted or delayed deliveries. From there, coal will be transferred to the underground conveyors using mobile equipment. The coal used in SWPS Unit 2 will have an ash content up to approximately 6.9%.

Around 80% of the total ash becomes entrained in the gas stream, and the remaining 20% is removed as bottom ash. SWPS Unit 2 is expected to generate approximately 13.8t (around 12,000kg) per hour of fly ash and bottom ash. Two new storage silos will take the material from SWPS Unit 2.

Potential HAP emissions from the proposed project were calculated to be almost 25t (22,000kg) per year for all units combined. City Utilities is anticipating controlling mercury emissions by injecting powdered activated carbon.

Twenty concrete piers form chimney foundation

Local company Carson Mitchell has sunk more than 20 concrete piers as part of the foundation for the 513ft tall concrete chimney. In some places, the piers have been anchored more than 25ft (8m) into the bedrock. The company bored a hole through each pier, inserted thick steel rods into the holes, and mechanically attached them to the bedrock. The steel was then stretched by more than an inch (2.5cm) and capped at the top of each pier, so locking pier to bedrock.

The chimney foundation is 10ft (3m) thick and 80ft (25m) in diameter. The cement was poured continually for maximum foundation strength, over a period of about 12 hours.

The concrete temperature had to be kept at about 75º despite the heat generated by the concrete itself, and ice was mixed into some concrete loads. The chimney was also completed by March 2010.

In November 2006, Pullman Power was contracted for construction of 513 foot tall SW2 chimney. The chimney construction was almost complete in March 2009. The Liner and shell construction has also been completed.

The balance of plant contract was given to Cherne Contracting Corporation in October 2008. The contract provided plant wide electrical and instrumentation construction, mechanical work for turbine and auxiliary equipment and high energy pipe installation.

Contracts

The project involved contracts for boiler island, balance of plant and coal handling. The boiler island is being constructed by Oscar J. Boldt Construction. The fuel preparation and emissions control of the boiler island was done by Foster Wheeler North America.

Coal handling contract was awarded to Brahma Group and is still underway. The balance of plant contract is being handled by Cherne Contracting Corporation.

Emerson’s Ovation system will monitor and control the boiler as well as the burner management system, cooling tower, air quality control system and balance of plant processes.

Bond issue approved

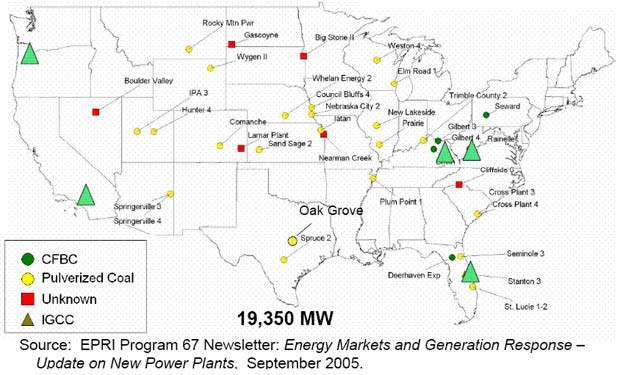

City Utilities looked at a variety of technologies, including subcritical pulverised coal, supercritical pulverised coal, atmospheric fluidised bed combustion, pressurised fluidised bed combustion, integrated gasification combined-cycle (IGCC), and renewable energy sources. These were felt not to be viable for meeting baseload energy needs, but City Utilities will continue to look for ways to use renewable energy.

The Permit to construct was given in December 2004 for 275MW net electrical output. Springfield voters approved a bond issue in June 2006 to allow the second coal-fired power plant to be built (a similar proposal was rejected in 2004). The plant will raise an average CU customer’s electric bill by $9.63 a month. CU cameras are following the construction, including time-lapse images of the chimney as it is erected. News and images are appearing on City Utilities website.