The Browns Ferry 1 reactor has been rebuilt, uprated, and returned to service in Alabama, USA. It was brought back on line in June 2007 after being shut down for two decades. The three Browns Ferry BWRs (Boiling Water Reactors) are now producing 3.4GW in total.

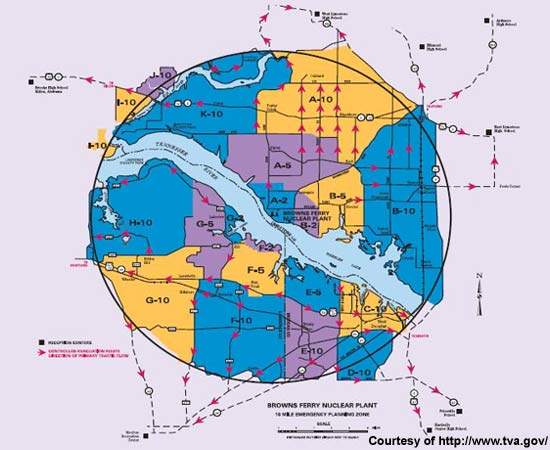

Browns Ferry 1 is on the north shore of Wheeler Reservoir. The plant is located on 340 hectares (840) acres beside the Tennessee River, near Athens, Alabama. It was TVA’s first nuclear power plant, and the first to generate more than 1GW when it came on line in 1974. The site licences start to run out in 2033.

Three boiling water reactors at browns ferry

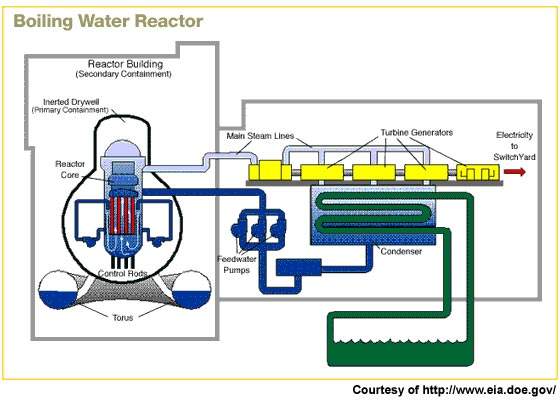

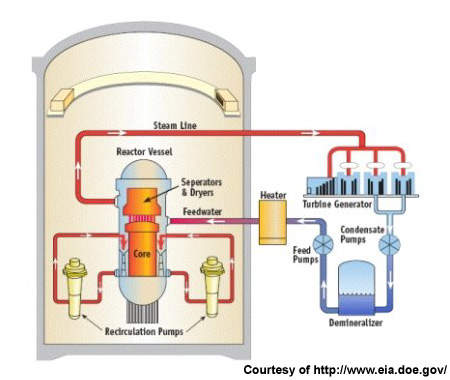

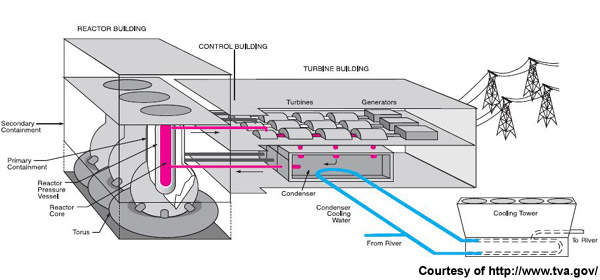

The plant has three General Electric boiling water reactors. Uranium pellets are stacked in tubes, and 75 to 94 of the tubes are bundled together into a fuel assembly.

Commercial boiling water reactors generate heat in the reactor core. Control rods are inserted into the reactor core to control power production. Pure water (reactor coolant) moves upward through the core absorbing heat to form a steam-water mixture. This leaves the top of the core and enters a two-stage moisture separation process. The steam is fed to the main turbine.

The steam is condensed back to water in the condenser and pumped back for reheating. The cooling water is force circulated by recirculation pumps. Emergency cooling water can be pumped by onsite backup diesel generators.

Construction began in 1966

Tennessee Valley Authority (TVA) was Architect Engineer and is plant operator for each of the three units. Construction at Browns Ferry began in 1966 and was completed in 1974 (Unit 1), 1975 (Unit 2) and 1977 (Unit 3). After major fire damage in 1975 unit 1 was repaired, and operated from 1976 through 1985. The winter net dependable generating capacity of the whole site is now 3,440MW.

In March 2002 Browns Ferry Unit 3 ran non-stop for 669 days before going offline for a scheduled refueling outage. In May 2002 the TVA Board voted to return Browns Ferry Unit 1, idle since 1985, to service. It generates more than 1,155MW of electricity, enough to supply about 650,000 homes. Units 2 and 3 can produce enough electricity to supply the needs of about 1.3 million homes.

There have been criticism that the units are old and needing an upgrade. The 1985 shutdown was the result of concerns about a fire years earlier, and the TVA was unable to convince the relevant Commission that the reactor could operate safely. It had not complied with federal safety standards, and economic performance had been poor.

All three units of the Browns Ferry plant were actually shut down in 1985, but they retained their NRC operating licences. Unit 2 came back on line in 1991, and Unit 3 in 1995 at a cost of US $1.8bn, which was also the estimated cost of restarting Unit 1.

One third of TVA power supply from nuclear

About 30% of TVA’s power supply comes from its three nuclear plants: Browns Ferry, Sequoyah and Watts Bar. In 2004, TVA nuclear plants generated a record 47,075,964MWh – more than enough for every household in the TVA service area.

In May 2005, TVA was recognised by the nuclear power industry for developing an index of 20 performance indicators that can lead to improved plant reliability and performance. Employees were presented with a Nuclear Energy Institute 2005 Top Industry Practice Award, which is the US nuclear industry’s highest recognition of excellence. The 20 indicators that make up the index focus on improving equipment performance, improving adherence to schedule, reducing the backlog of maintenance projects, and resolving equipment reliability issues.