Lackawanna Energy Center is a 1,485MW natural gas-fired combined-cycle power plant (CCPP) located in the Borough of Jessup, Lackawanna County, Pennsylvania, US.

The facility was developed by Invenergy in partnership with private equity and infrastructure investment firm First Reserve.

The Borough of Jessup granted permission for the project in December 2015, while the air quality permit for the plant was approved by Pennsylvania’s Department of Environmental Protection during the same month.

The construction of the Pennsylvanian energy project commenced in March 2016, and the facility started its commercial operations in January 2019.

Lackawanna Energy Center details

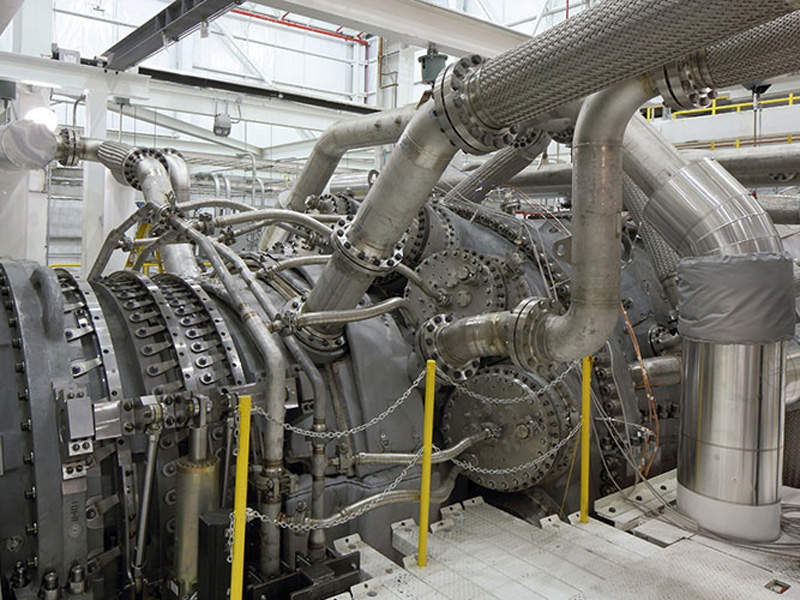

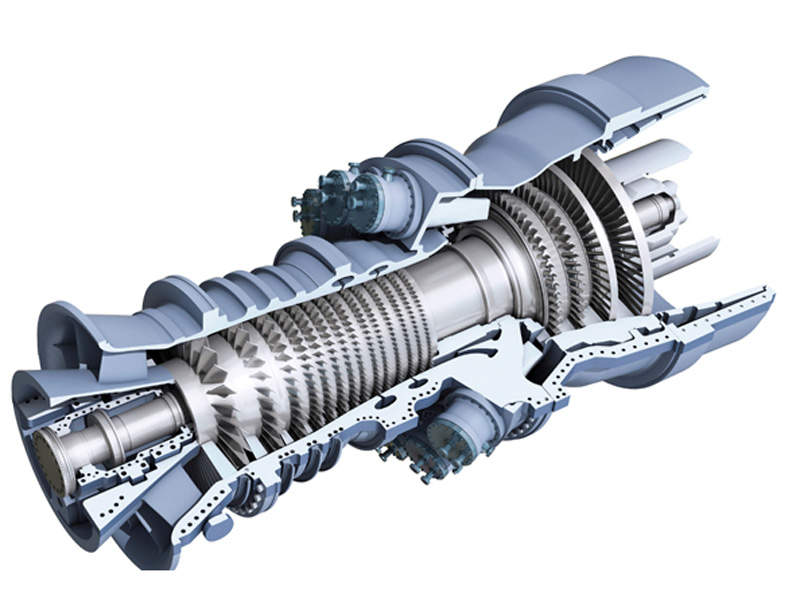

The CCPP is equipped with three General Electric (GE) 7HA.02 air-cooled, gas-powered combustion turbines, three heat recovery steam generators (HRSGs), integrating duct burners and a steam turbine.

Other major equipment includes a common fuel gas dew-point heater for the combustion turbines, a natural gas-fired auxiliary boiler, a diesel emergency generator and a diesel-powered fire water pump.

The combustion turbines burn natural gas to generate electricity. The HRSGs capture the exhaust heat from the turbines and feed the steam turbine generator to produce more electricity.

The facility also features storage tanks for diesel fuel, lubricating oil and aqueous ammonia.

Grid connection and gas supply details

Approximately 1,000MW of output from the project’s substation is conveyed via a 5.2mile (8.3km) long overhead transmission line to PPL Electric Utilities’ Lackawanna 230-69kV substation. Then it further connects with PJM’s interconnection system via a 230kV single-circuit line and two 138kV-69kV double-circuit lines.

Kinder Morgan subsidiary Tennessee Gas Pipeline Company supplied the natural gas required for the project.

Sustainability features of the Pennsylvanian CCPP

The power plant is equipped with a selective catalytic reduction (SCR) system to mitigate nitrogen oxide (NOx) emissions from the HRSGs.

Oxidation catalysts are used to control carbon monoxide (CO) and volatile organic compound (VOC) emissions from the combustion turbines and duct burners.

The turbine air-cooled system reduces the power plant’s water intake by approximately 90% compared to a water-cooled system.

The administration and control building at the facility won Leadership in Energy and Environmental Design (LEED) Gold certification for achieving 60% higher energy efficiency compared to conventional buildings.

A solar array was fitted on the roof of the building to produce clean energy.

Financing

Invenergy financed Lackawanna natural gas-fired facility in December 2016.

$1bn senior debt financing was provided by a group of lenders, including GE Energy Financial Services, Hana Financial Investment, Commonwealth Bank of Australia, ING Capital, BNP Paribas and MUFG.

Borough of Jessup power project contractors

The engineering, procurement and construction (EPC) contractor for the project was Kiewit Power Constructors.

CMI Energy supplied the boiler for the power plant while RM Controls was contracted to supply its proprietary Eslin insulation systems for the project.

IES Engineers performed the air quality and monitoring application review.

B&W Energy Services provided an advanced high-pressure water jetting AquaLazing service for the facility.

Benefits of Invenergy’s power project

The project created approximately 1,200 jobs during the construction period and 30 permanent jobs in the operational phase. It contributes approximately $50m to the region’s revenue.

The project also helps to replace the old coal-fired power plants in the area, which leads to a higher air quality in the region. It also helps the state to achieve the new carbon emissions reduction targets set by the US Environmental Protection Agency (EPA).