TAPROGGE

Optimisation of Water Circuits

For more than 50 years, the name TAPROGGE has represented innovation and competence in optimisation of water circuits, particularly cooling water circuits in power stations, desalination plants, refrigeration technology and industry. With some 15,000 TAPROGGE applications in more than 100 countries around the world, the company is at the forefront of this specialist field internationally.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

For more than 50 years, the name TAPROGGE has represented innovation and competence in optimisation of water circuits, particularly cooling water circuits in power stations, desalination plants, refrigeration technology and industry. With some 15,000 TAPROGGE applications in more than 100 countries around the world, the company is at the forefront of this specialist field internationally.

The company’s main product lines cover tube cleaning systems, filtration systems (especially backwash filters), water intake systems (pre-screening) and monitoring tools. These products are supported by integrated services, which guarantee the highest efficiency of all TAPROGGE modules in the water circuit and optimum performance of the end-user’s plant.

Water intake systems for the power industry

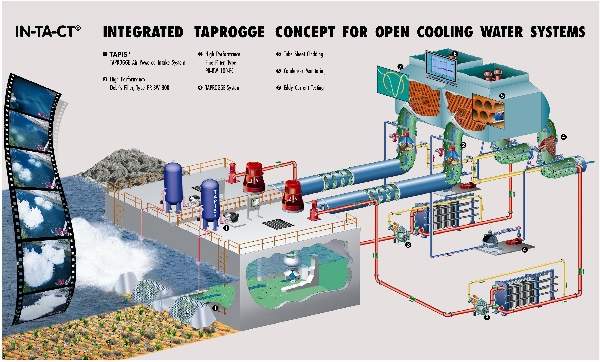

Pre-screening systems with coarse screens, fine screens and skip rakes are the conventional approach for water intake systems in once-through cooling water circuits with the requirement of large water quantities. Modern cooling water circuits use the single-stage concept TAPROGGE air-powered intake system (TAPIS®).

TAPIS is environmentally-friendly, with only the water directly taken from the water source; for this reason, there is no cost for the removal of any debris. Further savings are achieved by eliminating moving parts in the system to minimise maintenance costs, while capital expenditures for buildings and canals are also avoided.

High-performance filtration systems

TAPROGGE has been developing a wide range of filtration systems for everything from small to very large water quantities. They work as backwash filters with different sizes of filtration fineness from 1mm-9mm. Typically, filter types PR-BW 100 and type PR-BW 800 meet these requirements. For fine filtration, Dynamicfilter and PR-BW 100-FC filter types are the best choice, offering filter fineness down to 100µm. Special filters (e.g. ultrafiltration products) complete our range of solutions for high performance filtration.

Tube cleaning systems to prevent corrosion, leakages and shutdowns

Microfouling and scaling in the tubes of condensers reduce efficiency in power production. These losses cause a smaller output of energy and thereby cost you money. This loss can be avoided by using a TAPROGGE tube cleaning system. By circulating sponge rubber balls in the condenser cooling water circuit, a power output comparable to ‘as new’ can be achieved. Furthermore, tube cleaning systems help our customers avoid long-term problems, such as tube leakages due to corrosion and subsequent shutdowns.

Monitoring systems to optimise power plants

Monitoring the ball recirculation and the ball effectiveness contribute to the optimisation of the efficiency of the tube cleaning system and, consequently, of the end-user plant. Filteroptimiser monitoring systems minimise the operation cost of the filters.

In addition, a TAPROGGE condenser monitoring system provides comprehensive information on the status and the efficiency rate of the condenser and is an early indicator for problems developing in the system.

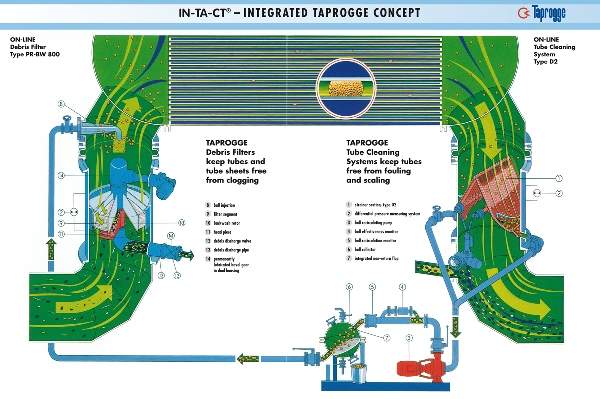

IN-TA-CT custom water circuit optimisation

All TAPROGGE hardware modules are combined in a user-specific concept to the highest benefit of our customers and end-users. Synergetic means that the complete system offers benefits greater than the sum of its parts. This is what we call: IN-TA-CT, the integrated TAPROGGE concept.

IN-TA-S integrated support services

Integrated TAPROGGE services (IN-TA-S®) covers the end-users’ requirements in terms of operation and maintenance of our systems in a comprehensive way during the complete system lifecycle, from the maintenance through to the operation. With the modular structure of the individual IN-TA-S services, you are free to choose the scope of our support. Using IN-TA-S you will gather qualification and competence on site as TAPROGGE our experts provide assistance and instruction.

With IN-TA-CT and IN-TA-S, TAPROGGE introduces its partners to a new dimension of target-oriented after-market care.

Contact Details

Website

Email Address

Address

58300 Wetter,

Germany