FACO

Heat Exchangers, Cleanable Coils, Safety Double-Tube Coils and Dry Coolers

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

FACO is a manufacturer of customised heat exchangers for use in the power industry, as well as in offshore, transport, food and hydro applications. FACO boasts 40 years of engineering expertise in the manufacture of heat exchangers and related equipment, including cleanable coils, safety double-tube coils and dry coolers.

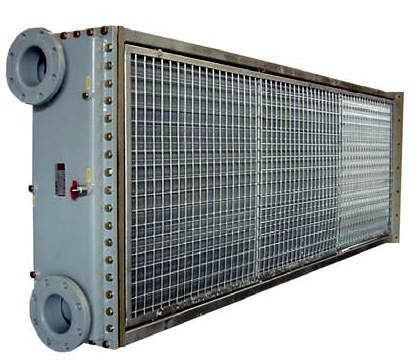

Cleanable coils

Manufactured with removable water boxes, or with tubular collectors and exchange tubes connected through plug-equipped nipples, FACO cleanable coils allow inspection and mechanical cleaning. These heat exchangers are suitable for fluids that contain polluting elements such as mud, weeds, micro-organisms and lime.

Safety double-tube coils

When it is necessary to prevent contamination of air or gas passing through the fins (by liquid escaping from any leaks in the tubes) the double-tube construction guarantees improved safety. Every tube of the exchange bundle is composed of two coaxial tubes, between which canals are obtained that convey any leakage towards collection chambers placed close to the tube sheets, where it can be detected without it escaping and thereby damaging other equipment.

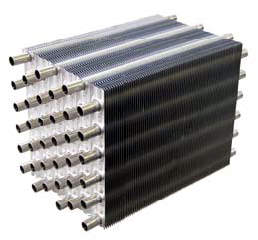

Finned-block heat exchangers

FACO’s finned-block heat exchangers are composed of tubes mechanically expanded into self-spacing collars die-formed on the fins, which have a waved profile studied in FACO’s thermo-dynamic research laboratory. The efficiency of this type of heat exchanger means that the cost/performance ratio is extremely good.

Dry coolers

FACO’s impressive engineering capabilities, together with high heat exchanger construction flexibility, a wide choice of materials and "custom-made" design, have contributed to the success of the company’s range of dry coolers, which are particularly used in generator sets, cogeneration and as liquid coolers in many production processes.

Custom-made dry coolers and condensers

The wide range of materials and tube patterns that are available for the production of finned-block heat exchangers, and FACO’s high production and design flexibility, allow FACO to supply custom-made dry coolers and condensers that are suitable for use with numerous fluids and in the most varied operating conditions, guaranteeing the best results in terms of performance and noise emission.

Heat recovery systems

In addition to multi-coil systems with conventional coils, FACO offers a wide range of specific equipment for heat recovery, including heat pipe, rotary heat exchangers and air-to-air plate heat exchangers.

Contact Details

Website

Email Address

Address

28040 Varallo Pombia (NO),

Other,

Italy