GEA Renzmann & Grünewald

Transformer Cooling Systems and Heat Exchangers

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

GEA Renzmann & Grünewald has been manufacturing heat exchangers and other process equipment for more than 60 years. The company’s wide range of products and services focus on transformer cooling systems, air technology and special applications.

Transformer cooling systems

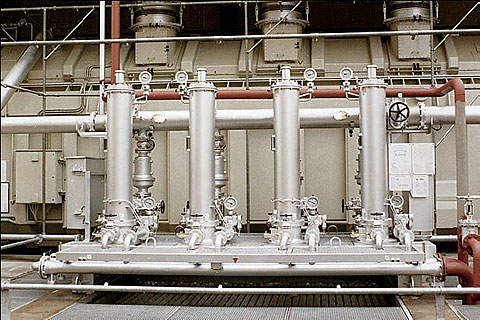

With experience in the design and manufacture of components and systems for this application, trust GEA Renzmann & Grünewald’s expertise to provide you with a highly reliable and efficient transformer cooling system. Our product offering includes transformer oil air coolers, transformer oil water coolers and transformer oil pumps as well as accessories.

Shell and tube heat exchangers

GEA Renzmann & Grünewald’s special applications division designs, engineers and manufactures various types of shell and tube heat exchangers. In addition, we design and manufacture services supply systems for power plants in close cooperation with our customers.

Our work focuses on achieving joint success with our customers and is devoted especially to developing technical improvements. For example, our double-tube safety technology has set new safety standards for chemical processing, power generation and gas preheating facilities.

Compact heat exchangers

GEA’s standardised compact heat exchanger series has been developed for industrial, process technological and power engineering applications.

Double-tube safety heat exchangers

Double-tube technology from GEA Renzmann & Grünewald optimises heat exchangers in economic and ecological terms. Available in many different materials and a wide temperature and pressure range, the heat exchangers are suitable for a large spectrum of applications.

Natural gas preheaters

Through the introduction of double-tube safety technology to gas preheating / cooling applications, GEA Renzmann & Grünewald has responded to the power industry’s demands for increased safety. Our natural gas preheaters are approved by DVGW 498 and 499 (DVGW = German Association of Gas and Water Engineers).

Heat exchangers for cooling and heating gaseous and liquid fluids

GEA Renzmann & Grünewald’s vast experience, gained over several decades, in the design and construction of heat exchangers has made us one of the leading suppliers of heat exchangers for cooling and heating gaseous and liquid fluids.

Our air technology division supplies heat exchangers of all sizes for a wide spectrum of applications, including heating and evaporation, cooling and condensation, and heat recovery.

Our success derives from our ability to supply a variety of different plain and finned tube systems, enabling us to solve the most diverse application problems.

Air coolers, heaters and preheaters

GEA Renzmann & Grünewald provides the following air technology:

- Air coolers and heaters for chemical and process applications

- Air heaters for drying facilities

- Air preheaters for waste incineration plants

- GEA Econorm systems for low energy consumption and thermal recovery processes

- Economisers for steam, oil, and hot water generation

- Waste gas cooling after thermal incineration

Heat exchanger variants

The D style heat exchanger is designed for higher pressures and meets standard official inspection requirements. The heating or cooling fluid connections are usually welded neck flanges designed to meet the requirements of the relevant pressure stage, whereas the heating and cooling surfaces are galvanised finned tubes.

The air connection frame is provided with a protective coating. Customised designs can be supplied. D style has the following variants:

- Style D5 – robust, welded design with a non-tight air-side connection frame

- Style D6 – robust, welded design without an air-side connection frame

- Style D7 – robust, welded design with an air-tight connection frame up to 1,000mm WG owing to a jacket; air-tightness is ensured by a gland

- Style D8 – same design as D7, but with a gas-tight connection frame up to 2,000mm WG and metal bellows

Finned and plain tube heat exchangers

GEA Renzmann & Grünewald provides both finned and plain tube heat exchangers. Finned tubes are indispensable components where heat is to be exchanged economically between gases and liquids or between gases and condensing vapours. For that reason, finned tube heat exchangers are preferably used to cool or heat gases, especially air.

Plain tube heat exchangers are mainly used for applications where a fluid flowing outside the tubes is subject to fouling to a point where finned tubes cannot be used.

Recooling systems

We offer recooling systems in galvanised steel, stainless steel, copper / aluminium and aluminium, as well as a number of other special styles.

After-sales services for cooling systems and heat exchangers

Our commitment to you does not end with product delivery. GEA Renzmann & Grünewald provides after-sales services that offer you maximum support and operational reliability of your equipment at all stages, from installation to servicing and maintenance.

Contact Details

Website

Email Address

Address

Monzingen,

Rheinland Pfalz,

55569,

Other,

Germany