Nol-Tec Systems specialises in the development and design of custom-engineered pneumatic conveying solutions, including standard as well as custom automation and bulk material handling systems. We are an industry-leading provider of dry sorbent injection and ash-handling systems for air pollution mitigation processes.

MATS and MACT air pollution mitigation processes compliant

Nol-Tec’s customers include both utility/power energy-generating units (EGUs) and industrial boiler users. Our air pollution mitigation processes are proven to comply with the EPA’s MATS regulations for EGUs, working with utility companies of a variety of sizes throughout North America. We also work with industrial boiler owners, providing guaranteed compliance with MACT regulations.

Dry sorbent injection

Nol-Tec offers Sorb-N-Ject®, dry bulk material handling systems and duct injection to mitigate SO2, SO3, Hg and HCl emissions effectively and efficiently. Sorb-N-Ject systems are custom-engineered to continuously transfer dry sorbent materials from storage silos to injection ports on boiler flue gas ducts. Nol-Tec utilises its initial area of expertise, pneumatic conveying, to ensure an uninterrupted flow of dry sorbents of many varieties, including hydrated lime, trona, sodium bicarbonate and powder activated carbon.

Nol-Tec’s designs incorporate unique features to prevent common problems, such as blockages and leakage of sorbent.

Dense and dilute phase conveying

Nol-Tec’s core expertise began in the area of pneumatic conveying. We specialise in both dense and dilute phase conveying to transport materials for the dry sorbent injection process. Our services include material testing, systems integration, installation, technical assistance, on-site start up, turnkey services and systems training.

Dense phase pneumatic conveying systems utilise relatively high pressure, low-volume gas as the motive force to transfer powder or granular bulk solids through a pipeline at low velocity. Dilute phase conveying systems use low-pressure, high-volume gas to transfer powder or granular bulk solids through a pipeline in an airborne state.

Unique system design features

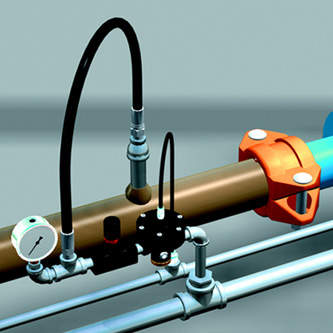

Nol-Tec’s proprietary Air Assist technology is used in our conveying designs to overcome the overall resistance in the convey line, distributing conveying energy throughout the line. Air Assist valves are strategically placed throughout the system, resulting in increased conveying efficiency and reliability. Nol-Tec’s high-pressure manifold design prevents ‘back-feeding’ from the main convey line, which could be experienced with low-pressure manifold systems.

In a recent design innovation, Nol-Tec utilises resistive splitting to inject sorbent into flue gas ductwork. This creates uniform dispersion from each lance for more complete coverage throughout the duct. And that decreases sorbent use, while increasing sorbent efficiency, through better interaction between the sorbent and flue gases.

Nol-Tec is also utilising air classified milling in conjunction with its Sorb-N-Ject technology. Regulations have expanded to require removal of HCl and SO2, as well as SO3, so that more types of sorbent must be used. We are proving that sodium bicarbonate is effective for this wider range of pollutants. Milling ensures that particle sizes are at their most efficient, and air classified milling works well on both trona and sodium bicarbonate.

Portable sorbent injection

Nol-Tec developed the portable Sorb-N-Ject systems for temporary, on-site sorbent injection. These systems are perfect to test the effectiveness of various sorbents, determine proper injection locations, verify the quantity of sorbent chemical required, provide pollution mitigation during installation of a permanent system, or supply temporary injection when needed, such as during the ozone season.

Sorb-N-Ject testing systems are compact, but complete. We bring everything to your site, in self-contained semi-trailers. We even have self-erecting silos to minimise installation time and costs. Our trained technicians integrate the equipment with your current system, track and report results, and dismantle the portable unit when your test or temporary need concludes. Sorb-N-Ject temporary systems help you avoid unnecessary capital costs and ensure your system design precisely fulfills your air pollution mitigation needs.

Nol-Tec experience and expertise

Founded in 1983, Nol-Tec Systems leads the market in custom-engineered pneumatic conveying solutions, working with manufacturers, materials processors and electrical generators throughout the world. Our team of experts will custom-design and install dry bulk material handling systems that ensure your materials are conveyed efficiently and effectively, in a manner precisely suited to meet your individual goals. Our systems cover a broad range of capabilities and components, including dense and dilute phase conveying, integrated controls and dry sorbent injection and emissions control systems. Nol-Tec balances sound technical expertise with innovative thinking, partnering with our forward-thinking customers to exceed their expectations and deliver success.

Learn how our solutions can meet your air pollution mitigation needs. Contact one of our experienced systems application engineers by completing the form below.