Teddington Engineered Solutions

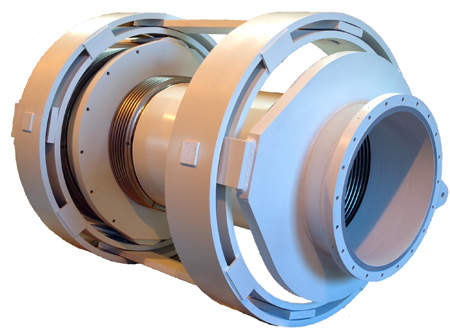

Bellows and Expansion Joints

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Teddington Engineering Solutions offers the most comprehensive range of bellows and expansion joint solutions in the industry through the amalgamation of Teddington Bellows, Brockington & Scott and Vokes GenFlex.

The combined strengths of the three formerly independent bellows manufacturers (established in the 1920s), and experience in the design, application and manufacture of bellows expansion joints, ensure that we are a world leader in our field.

Bellows and expansion joints for power generation and distribution

Teddington Engineering Solutions designs and manufactures bellows and expansion joints for any application in any medium. We have over 80 years’ experience in providing standard and bespoke products in power distribution, power generation (conventional fossil fuel and gas, and nuclear), diesel engines and generator sets, and district heating. Our range of products and services includes the following:

- Metallic bellows / expansion joints

- Rubber bellows

- Fabric bellows

- Metallic hoses

- PTFE bellows

- CNC precision machining

- Fabrication services

- NDT services

- Engineering design services

Market-leading bellows

Through product innovation and growth, Teddington Engineered Solutions now holds exclusive rights to some of the most successful brands in the industry, including Teddington, Vokes GenFlex, Brockington, Alpha and MaxComp.

Teddington bellows have been an assured choice for the power generation, power distribution, oil and gas, chemical, steel and general industrial markets since the 1950s. This background, combined with the skill of our employees and partners, ensures the best service to our customers.

Standard and custom bellows

Bellows are made in standard incremental sizes from 10mm to 6,000mm, although with our unique convolution forming processes there is almost no limitation to the size of bellows we can manufacture.

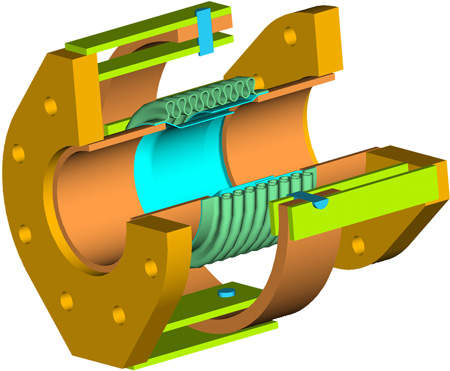

Best-practice metallic bellow design and manufacture

As one of the original contributors of the empirical data employed in establishing the bellows calculation formulae, Teddington Engineered Solutions designs and manufactures our products in accordance with the latest Expansion Joint Manufacturers Association (EJMA) code, which is universally accepted as best practice for the design and manufacture of metallic bellows.

In addition, we were recognised by BSI in 2005 to sit on the Euro Norm Committee for the development of a new standard in bellows design, manufacture and testing, EN 14917.

Specialist and customised bellows

Teddington Engineered Solutions offers customised bellows, designed to operate under severe conditions of temperature and pressure, from -190°C to +1,200°C, and from full vacuum to more than 200bar pressure. We specialise in thin-wall bellows and manufacture with membranes of single or multi-ply construction. We provide the following specialist bellows:

- Single and multi-ply

- Thin wall or thick wall

- Small through to large diameter

- Round and rectangular

- Full vacuum through to high pressure

- Cryogenic through to high-temperature applications

- Metallic and non-metallic

Our engineers have a wide experience of applications and will help you select the appropriate material based on pressure containment, cyclic life, temperature and corrosion-resistance needs. We routinely manufacture products from a variety of stainless-steel grades, nickel alloys, titanium and aluminium.

Testing, fabrication, welding and machining services

Teddington Engineering Solutions offers a full range of services, including:

- Dye-penetrant testing

- X-ray testing

- Ultrasonic testing

- Hydraulic testing

- Helium testing

- Fabrication services

- Welding services

- Conventional machining services

- CNC machining services

Assured-quality expansion joints

Staying at the forefront of the expansion joint industry, Teddington Engineered Solutions is accredited and works to the highest quality standards, including ISO 9001:2000 and ISO 14001. We were among the first expansion joint manufacturers to gain accreditation to the European Pressure Equipment Directive (PED 97/23/EC).

We offer products and services with guaranteed reliability in the field, delivery when you want it (standard or fast-track), more than 80 years of experience in design and manufacture, a dedicated team of engineers and account managers, and comprehensive solution packages from the design stage of a piping system through to NDT services.

Bellows for the defence, aerospace, nuclear and shipbuilding industries

The defence, aerospace, nuclear and shipbuilding industries continue to demand the highest quality. Teddington Engineered Solutions is proud of the reputation and expertise we have developed in producing products for these markets. The basis of the substantial growth we have enjoyed in these markets is delivery on-time, every time, with exceptional product quality.

Contact Details

Website

Email Address

Address

Dafen Park,

Carmarthenshire,

Llanelli,

SA14 8QW,

Other,

United Kingdom