HOTSTART is a world leader in the development and implementation of engine heating solutions. We design and manufacture engine pre-heaters that improve the reliability of generators, locomotives, large trucks, ships, heavy machinery and gas compression equipment. HOTSTART is based in Spokane, Washington, US.

The company has a subsidiary called HOTSTART GmbH in Siegburg, Germany; an oil and gas sales office in Katy, Texas, and an office in Tokyo, Japan.

HOTSTART engine heating solutions

HOTSTART offers engine heating solutions that are safe, cost-effective and environmentally sound. We work to provide either off-the-shelf or custom designed solutions for your specific needs. HOTSTART’s heating products keep engines always ready, even in extreme environments.

Tests by a major engine manufacturer found that engine cold starts account for up to 90% of damaging wear. HOTSTART products are designed to circulate pre-heated coolant through an engine, keeping it at operating temperature and eliminating damaging cold starts. The benefits of engine heating include longer engine life, reduced fuel consumption, fewer emissions, and reduced maintenance and energy costs.

HOTflow™ technology keeps engines ready

HOTflow™ heating systems feature an integrated pump that circulates warm coolant throughout the entire engine at uniform temperatures. Constant circulation of the coolant eliminates hotspots that can deteriorate heater hoses, harm engine seals and diminish coolant life. HOTflow™ heaters rely on fewer heating cycles, saving up to 2,000 kilowatt-hours a year in energy consumption, while extending heater element life and reducing maintenance work.

Efficient engine heating systems

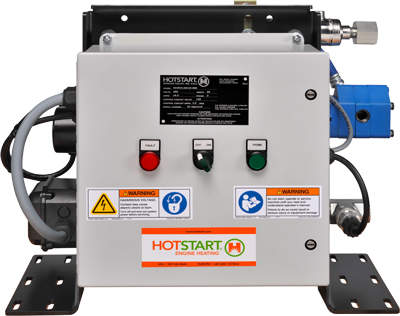

HOTflow™ heating systems are available in two different models. The CSM model heats engines ranging in size from 15l-100l displacement. The pump-driven CSM offers more efficient heating than thermo-siphon tank heaters, delivering uniform heating throughout the entire engine. On larger engines, one CSM eliminates the need for two thermo-siphon tank heaters, reducing the cost of installation and material. The heater is UL listed to the US and Canadian safety standards with CE compliant models available.

The CSM is a turnkey system, which includes all required controls and a 10GPM circulating pump. Forced circulation of the coolant extends element life and offers a significant reduction in electrical consumption. Outlet temperatures are greatly reduced, which results in extended hose life and reduced maintenance. The compact design requires minimal space for mounting and requires less installation time compared with two tank style heaters.

It is available in 3KW, 6KW, 9KW and 12KW with all standard voltage ratings in 50Hz or 60Hz. CSM preheaters meet requirements for installation on any UL 2200-listed generator set.

The CTM model heats engines up to 20l displacement and features an integrated pump that circulates coolant throughout the engine and improves flow through exterior plumbing restrictions. Forced circulation delivers uniform heating and allows the heating element to energize less frequently than an equal wattage thermo-siphon heater. This reduction extends heater element life and reduces energy use by up to 30%.

Circulating the coolant eliminates hot spots in the cooling system and reduces outlet temperatures. With outlet temperatures lower than typical tank style heaters that rely on thermo-siphon, heater hoses and engine seals last longer for overall improvement in heater reliability. The CTM’s compact design requires minimal space for mounting. It features a fixed thermostat controller and is available in 1kW, 1.5kW and 2.5kW, as well as in 120V and 240V.

Comprehensive engine heating solutions

Whether you require 18kW or 144kW of power to heat your prime mover, HOTSTART offers turnkey, pre-packaged systems complete with pump / motor, high-limit temperature controller, adjustable thermostat and control box for manual or automatic operation. Engineered to meet the needs of global engine users in every possible industry, these heating systems provide uniform heating to all locations in the engine, enhancing availability and decreasing wear and tear from cold startups.

HOTSTART success

HOTSTART was established in 1942 with the original patent for engine coolant heating. Our products are manufactured in the US, following ISO 9001:2008 processes and meet the extensive demands of our customers.

Throughout the company’s history, HOTSTART has partnered with customers to provide engine heating solutions that achieve their exact specifications and unique requirements. Global companies such as Caterpillar, MTU, Komatsu and others trust HOTSTART with their critical engine heating needs.

We are committed to a greener future and that commitment is best seen in HOTSTART’s in-house state-of-the-art testing cold room. This facility allows us to replicate the world’s toughest environments, down to -30° F temperatures. We regularly subject our products to cold testing to ensure their performance and ability to start engines in the most severe temperatures. If you have a specific concern for your engine’s performance, we will bring it in and do the testing for you.

Contact HOTSTART today to learn how you can save money by preheating your prime mover while improving availability and decreasing maintenance costs.