SBUNGE Automation

Automation, Operation and Maintenance Services for Utilities Equipment

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

We offer cost-saving services by automating, operating and maintaining our clients’ utilities equipment. By utilities we refer to steam plants (including boiler and steam distribution), compressed air plants (including compressors and air distribution), electrical reticulation (including switch gears and relays) and water plants (including waste water treatment).

Utility plant surveys

We carry out plant surveys, identify problem areas, quantify solutions, report back to the client, take note of the client’s instructions, make changes to the solutions, implement solutions, monitor progress and make adjustments where necessary.

We create performance indicators as a monitoring window to ensure that the agreed upon parameters are maintained at all times. These indicators give us a very good control measure and are critical for both parties to be at the same page at all times.

Since our solutions are retrofitted in many cases, we carry the capital cost of all hardware and software we install as part of automation. We have one central control room in our head office from where we monitor and control all our clients’ plants. The field operators follow the instructions of the control room operators at all times to ensure proper control of our performance.

Production plans and maintenance programmes for utility plants

We train our own operators to ensure that each one knows our expectations. These expectations include production requirements, health precautions, safety precautions, environmental constraints and the general well being of people.

In all instances of our operation we design site-specific, production plans and maintenance programmes. We implement, run and continuously improve the integrity of collected equipment data.

Steam plant services

We design and operate site-specific:

- Steam leakage control programmes

- Pipe layout networks

- Condensate return systems

- Energy recovery systems

- Fuel consumption reduction programmes

- Stack emission control programmes

- General maintenance programmes

Compressed air plant services

We design and operate site-specific:

- Air leakage control programmes

- Pipe layout and capacity networks, including receiver sizing

- Energy recovery systems

- Point of use air consumption control systems

- General maintenance programmes

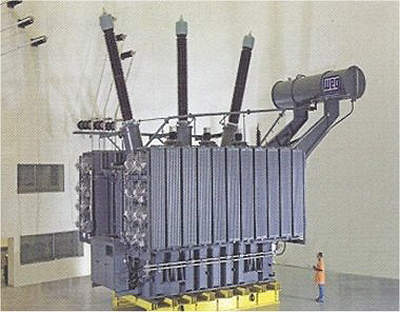

Electrical reticulation services

We design and operate site-specific:

- Tripping battery monitoring systems

- Switchgear management systems

- Cable sizing and laying

- Motor control panel management systems

- Fault monitoring programmes

- General maintenance programmes

Water plant services

We design and operate site-specific:

- Water processing systems

- Water distribution systems

- Leakage monitoring programmes

- Efficiency improvement programmes

- General maintenance programmes

Contact Details

Website

Email Address

Address

Amanzimtoti,

Durban 4126,

Other,

South Africa