IMR Hamburg

Installation of LP, IP and HP Piping

IMR Hamburg specialises in pipeline construction for power stations and industrial facilities worldwide.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

IMR Hamburg specialises in pipeline construction for power stations and industrial facilities worldwide. We offer services on a long-term basis, starting with planning and the supply of materials and with rational as well as economical production included.

Our performance spectrum includes consultation, planning, piping and spool construction, calculation, delivery and assembly, commissioning and documentation, as well as revisions including quality assurance and project management.

HP, IP and LP piping systems

We have become particularly well-known in the high-pressure field, processing all kinds of materials from high-alloyed ‘P92’ 1.4901 to plastics. The planning of IP and LP piping are CAD / CAE backed with ISOGEN based software solutions from Intergraph PP&M Smart Plant and SIGMA Rohr2 stress analysis according to ASME B31.1, B31.3, B31.4, B31.5, B31,8, Cl.1 Cl.2, Cl.3, EN13480, Stoomwezen D1101, KTA 3201.2, KTA 3211.2, FDBR, AGFW FW401, ISO14692, British Standard 7159, KRV, Wavistrong GFK.

We can process pipelines in all shapes and sizes. Pipe cutting, bevelling and assembling are always supervised from internal quality management. Documentation and pressure testing is implemented. We supply project detail engineering and material management for LP, IP and HP piping, fittings, flanges, bar and valves.

We have WPQR and comprehensive experience for the typical power plant, boiler and pressure vessel, process, pharma, shipping and offshore industry piping material range:

- S235JR/St37-2 (DIN material no 1.0037, ASTM A29…A853)

- S355 (DIN material no 1.0045, ASTM A572 50)

- P235GH (pipe DIN material no 1.0345, ASTM A53 A)

- P250GH/C22.8 (flanges DIN material no1.0460, ASTM A105 down to -10°C)

- P265GH (pipe DIN material no 1.0425, ASTM A53 B and/or A106 B)

- P275NL1 (pipe DIN material no 1.0488, ASTM A350 LF1 and/or A662 A)

- 16Mo3 (pipe DIN material no 1.5415, ASTM A335 P1/P11)

- 13CrMo4-5 (pipe DIN material no 1.7335, ASTM A335 P12)

- 10CrMo9-10 (pipe DIN material no 1.7380, ASTM A335 P9/P22)

- ‘P91’ (X10CrMoVNb9-1) (pipe DIN material no 1.4903, ASTM A335 P91)

- ‘P92’ (X10CrWMoVNb9-2) (pipe DIN material no 1.4901, ASTM A335 P92)

- X20CrMoV11-1 (pipe DIN material no 1.4922, ASTM A335 old)

- ‘Wb36’ (15NiCuMoNb5-6-4 ) (pipe DIN material no 1.6368, ASTM A335 P9)

- ‘Duplex’ (pipe DIN material no 1.4462, ASTM A789,790 S32205)

- ‘V2A’ X5CrNi18-10 (pipe DIN material no 1.4301, ASTM A312 304)

- ‘V4A’ (X5CrNiMo17-12-2) (pipe DIN material no 1.4401, ASTM A312 316)

- X6CriNiTi18-10 (pipe DIN material no 1.4541, ASTM A312 321)

- X6CrNiMo17-12-2 (pipe DIN material no 1.4571, ASTM A316Ti)

All other WPQR can be achieved within three weeks with our certification partners TUEV Nord and TUEV Rheinland, which also cooperate with ASME and other international certification bodies.

Piping prefabrication

We perform piping prefabrication at our Bakum (Germany) facility. Our products and capabilities include:

- Welded shaped parts

- Spool fabrication and ready-to-install pipeline systems

- Spiral tube bundles and wall tubes

- Material supply and management for prefabrication orders

- Fabrication engineering and schedule control

- Optimisation of the spool distribution of piping systems

- Cutting with circular / band saws

- Post-welding heat treatment with induction and resistance heating and annealing furnaces, including solution annealing

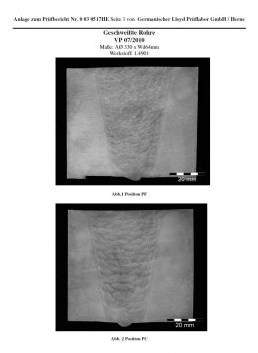

- Non-destructive tests: hardness, ultrasonic, X-ray, MT, PT, metallography, microscopy

- Cut wire shot and glass pearl sandblasting

- Corrosion protection

- Spool approval and quality documentation according to DGRL and ASME

Certificates and approvals for pipeline construction

We have the following certificates and approvals:

- DIN EN ISO 3834-2:2005

- ISO 9001: 2008 – industry assembling, piping and engineering, welding

- Pressure Equipment Directive PED 97-23-EU AD2000 HP0

- SCC**:2006

- WHG water protection awareness

- DIN 18800-7:2008-11 class E (certification of manufacturer’s qualification for welding steel structures in Germany and in Europe according to EN1090-2 EXC2)

Industrial plant construction

We offer industrial plant construction services for all types of media and with all types of DIN EN ISO and ASTM materials. Our special strength lies in the processing of all types of materials, from high-alloyed steels and non-ferrous metals to plastics like polyethylene, polypropylene or glass-reinforced plastic. As a contractor we have designed, delivered and assembled industrial plants and components for many industry branches. We are active in the following industrial fields:

- Prefabrication, supply and assembly

- Commissioning and documentation

- Quality assurance and project management

Power plant service

We ensure availability for revision, maintenance and renovation in power plant installation services. With the ‘IMR System Diagnostics’ we have created instruments that on the basis of VGB- Directive R 509 link together safety and efficiency. Our services include:

- Planning, construction and calculations

- Prefabrication, supply and assembly

- Commissioning and documentation

- Quality assurance and project management

Contact Details

Website

Email Address

Address

D-22047 Hamburg,

Germany