Ash Issues When Firing Alternate, Engineered and Opportunity Fuels

Alternate, engineered and opportunity fuels can offer a sustainable and renewable alternative to fossil fuels and traditional biomass fuels for industrial steam generation.

Detroit Stoker Company is a global leader in the design, engineering, and manufacturing of solid fuel stoker/grate combustion systems, along with integrated burners and ash/material handling equipment for industrial and renewable energy applications. Our technologies are in operation at thousands of installations worldwide, generating over 60,000 tons of steam per hour using biomass, refuse-derived fuels, municipal solid waste, and other alternative energy sources.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Detroit Stoker Company designs combustion equipment capable of efficiently processing a diverse range of fuels. With extensive experience handling everything from agricultural and municipal refuse to engineered biomass and fossil fuels, Detroit® combustion systems are trusted worldwide for their adaptability and performance.

Our combustion solutions have successfully processed agricultural byproducts such as bagasse, corn stover, grape pomace, and poultry litter; industrial wastes including tire-derived fuel, sludges, and carpet scraps; and engineered fuels like RDF pellets, coal pellets, and wood pellets.

Detroit® combustion equipment is also optimized for conventional and alternative fossil fuels, including bituminous coal, lignite, and powder river basin coal, as well as various wood residues—from sawdust and bark to demolition debris and urban wood waste. This extensive fuel flexibility ensures our systems can meet the evolving needs of energy producers, industrial processors, and waste-to-energy facilities around the world.

A Legacy of Innovation Since 1898

Since its founding in 1898, Detroit Stoker Company has remained a global leader in solid fuel combustion systems and equipment. From the development of the original Detroit® “V” Type Stoker and the issuance of its first patent in the same year, to new innovations like the Detroit® HADES Burner, Pellet Metering Feeder, and Bagasse Triple Drum Feeder the company has continually advanced combustion technology. Over the decades, Detroit Stoker has expanded its capabilities through product development, and acquisitions—including the creation of groundbreaking technologies like the RotoGrate, Hydrograte, and RotoStoker VCG. Headquartered in Monroe, Michigan since 1922, Detroit Stoker has played a pivotal role in shaping industrial steam generation using coal, biomass, municipal solid waste, and other renewable fuels. With over 125 years of proven experience, Detroit Stoker Company continues to deliver environmentally responsible solutions that support industrial heat, processing, and electric power generation around the world.

Why Choose Detroit Stoker Company – Trusted Engineering, Service, and Support

Detroit Stoker Company brings over a century of proven expertise to every combustion solution we deliver. As the world’s leading manufacturer of solid fuel burning stokers, our skilled engineering team works closely with clients from design through operation to ensure high system availability, improved efficiencies, and extended equipment life. We are fully committed to aftermarket parts and service, offering genuine Detroit® replacement components that incorporate continuous design improvements for peak performance—even on equipment from other manufacturers. Our global support network includes a dedicated sales team, trained field technicians, and sales representatives across multiple regions. With solid financial backing, a complete service portfolio, and 24/7 emergency support, Detroit Stoker Company delivers reliable performance and responsive service that power our customers’ long-term success.

Alternate, engineered and opportunity fuels can offer a sustainable and renewable alternative to fossil fuels and traditional biomass fuels for industrial steam generation.

How to employ innovative burner systems and controls for optimum environmental efficiency.

Properly sizing your aggregate dryer burner for optimum plant production should be a straightforward exercise; however, in many cases the burner is sized for significantly more than typical plant operating practices or even production capability.

Detroit Stoker continues to pursue new biomass projects specifically designed for wood pellets and alternative biomass fuels.

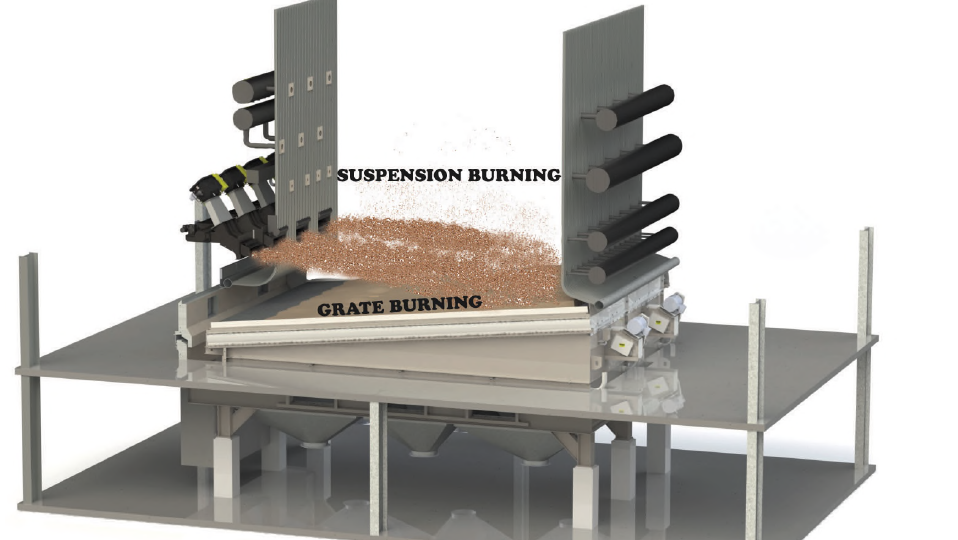

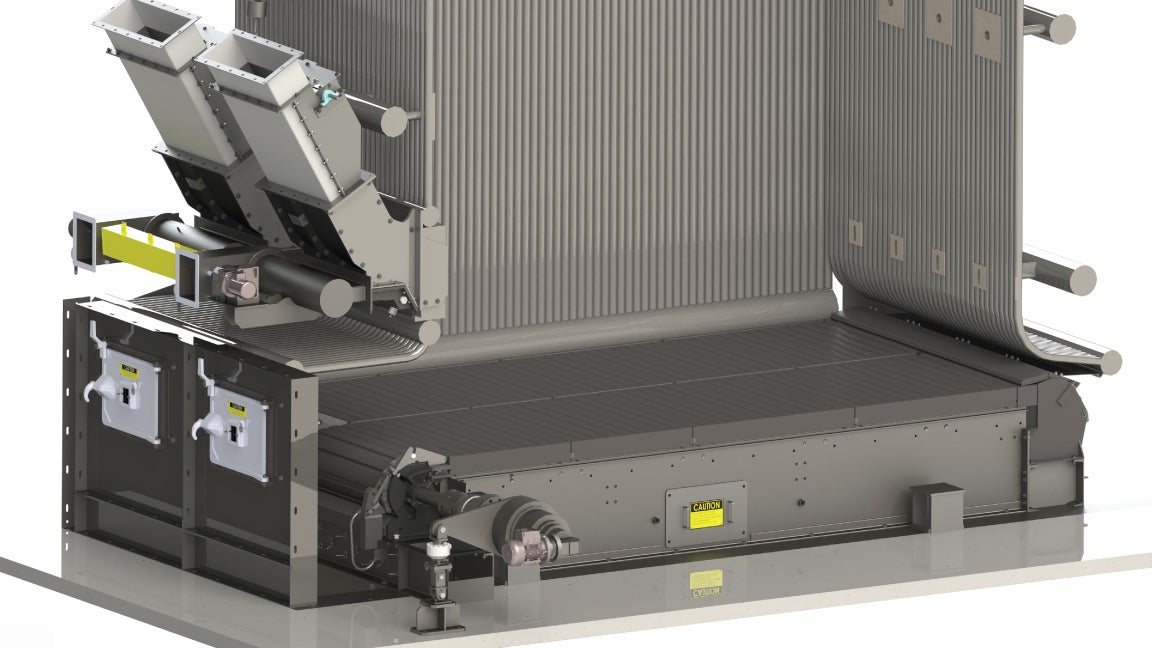

The Detroit® RotoGrate Stoker is a traveling grate spreader stoker designed for high-ash and low fusion fuels.

Detroit® Burner Systems are designed for durability, flexibility, and reliable performance across a wide range of industrial and utility boiler applications.

The Detroit® HADES Burner is a sealed-in burner developed for hot aggregate drying applications.

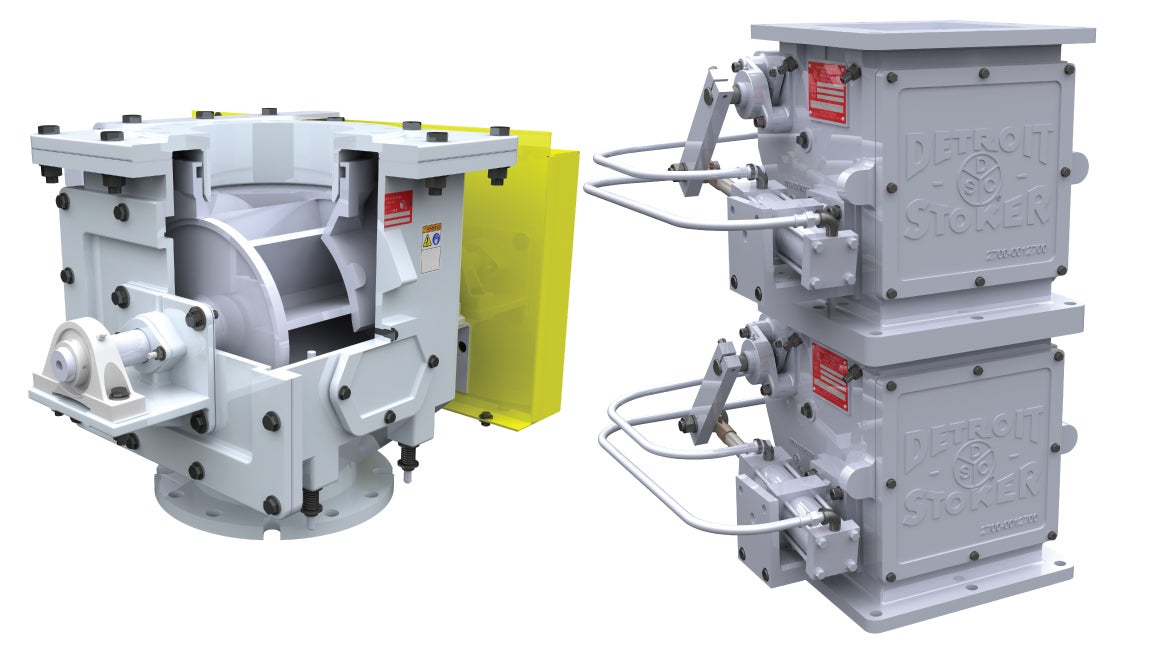

Detroit® Rotary Seal Feeders are engineered to handle abrasive and high-temperature materials with durability and efficiency.

Detroit® Ash Handling Systems are designed to transport ash from combustion units burning coal or solid refuse fuels, ensuring safe, clean, and economical ash disposal.

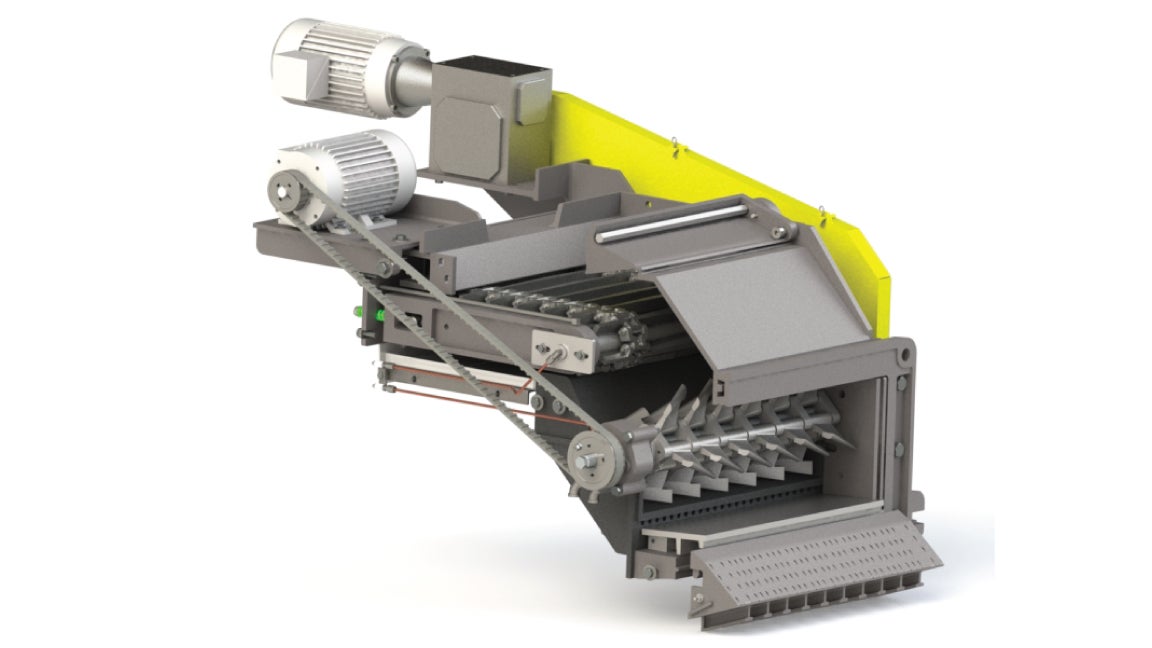

Detroit Stoker Company designs a range of fuel distributors to meet the specific demands of solid fuel combustion systems, ensuring precise and even fuel delivery across the stoker grate surface.

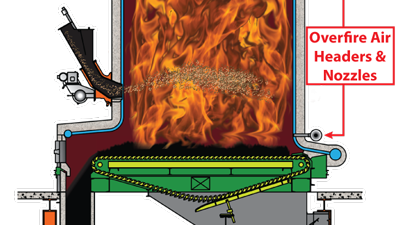

Detroit Stoker Company’s Overfire Air (OFA) and Secondary Air Control Systems are designed to enhance combustion and reduce emissions.

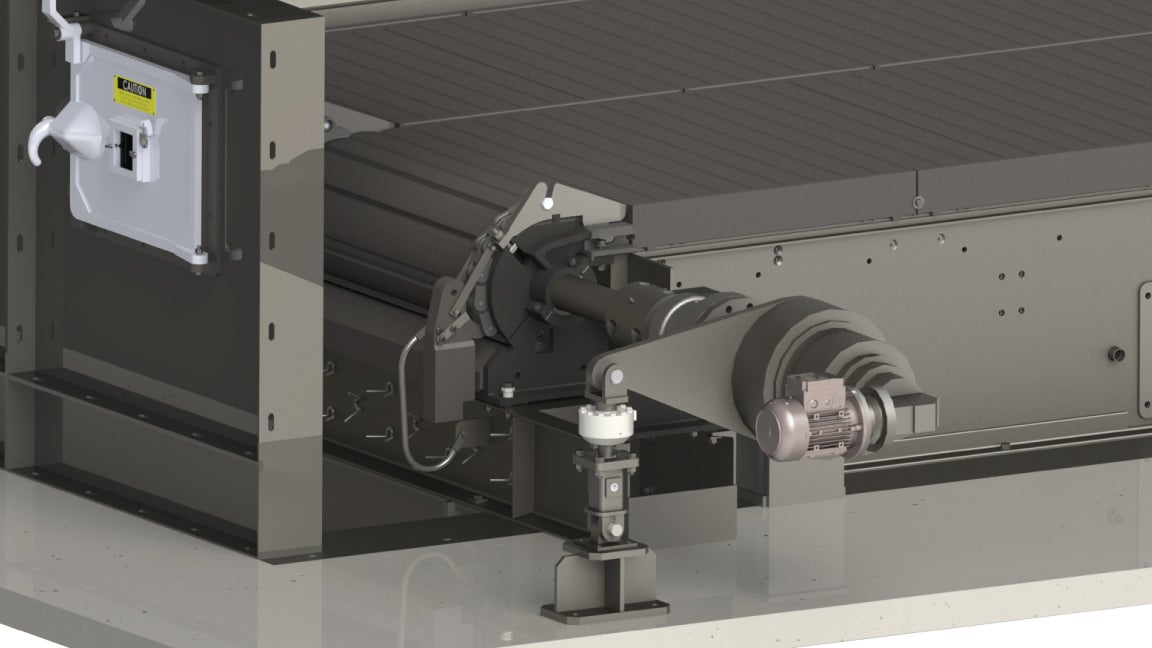

The Detroit® Planetary Grate Drive with Load Cell offers a modern solution to common stoker drive problems.

Detroit Stoker Company provides comprehensive service and support for solid fuel combustion systems, specializing in the maintenance, inspection, and upgrade of stokers/grates, fuel handling, and ash systems.