EXHEAT is a world leader in the design and manufacture of electric process heaters and associated thyristor control systems for both non-hazardous and hazardous area equipment.

Equipment can be supplied to meet both IEC and NEC requirements. Where it is to be installed within a hazardous area product certification can be supplied from all appropriate bodies.

Electric process heating equipment

EXHEAT can design and manufacture electric process heating equipment suitable for installation within the extreme environments commonly found in the oil, gas and petrochemical industries.

EXHEAT products are typically used in the following product applications:

- Glycol reboilers

- Continuous catalyst regeneration (CCR) processes

- Fuel gas treatment systems

- Natural gas applications such as pressure reduction stations

- Molecular sieve regeneration

- Heating mediums

- Crude oil

- KO drums

- Dry gas seals

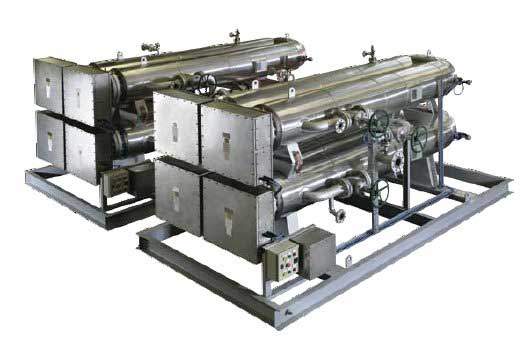

Complete process heating systems

EXHEAT designs and manufactures complete process heating systems. This includes the complete design and supply of skid-mounted or packaged equipment. EXHEAT takes responsibility for all stages of project execution, including initial study; mechanical, electrical and process design; skid assembly for mechanical, electrical and instrumentation; in-house manufacturing and testing; and site supervision, commissioning and training.

Hazardous area process heaters

EXHEAT manufactures a large range of hazardous area process heaters. The ISES range of electric heaters comprises a variety of process flow heaters that are certified for use in a Zone 1 or Class 1, Div 2 hazardous area. They are custom-built to client specifications.

The FP/BFP range of flameproof electric heaters comprises a variety of process heaters certified for use in a Zone 1 or Class 1, Div 1 hazardous area. They too are custom-built according to client specifications.

Hazardous area immersion heaters

The ISES range includes process immersion heaters that are certified for use in a Zone 1 or Class 1, Div 2 hazardous area. The FP/BFP flameproof electric heater range also incorporates process immersion heaters, certified for use in a Zone 1 or Class 1, Div 1 hazardous area. Both types are custom-built to meet client specifications.

Cast aluminium line heaters

EXHEAT’s cast aluminium line heaters provide an effective heating solution for constant flow liquids or gases. The design incorporates electric heating elements and an indirect process heating coil imbedded with marine-grade cast aluminium, providing excellent heat transfer properties combined with low surface temperatures.

Electric process heater skids

EXHEAT designs and manufactures electric process heater skid packages which can be engineered to meet specific requirements. They include:

- Electric process heaters

- Simplex or Duplex filter

- Flow measurement

- Isolation / bypass valves

- Flow control valves

- Thyristor / contactor control system

- Temperature measurement instrumentation

- Pressure measurement instrumentation

This is just a sample of the electric process heating equipment that EXHEAT can provide. Other products include air warmers, convector heaters, radiators, fan heaters, enclosure heaters, portable immersion heaters, thermostats, air duct heaters, control systems, and many more. Contact EXHEAT or visit the website to find out more.