US Photonics is a Missouri-based technology company. US Photonics develops advancements in cutting-edge batteries and battery systems that will revolutionise the entire battery and electronics industries by utilizing their research of new anode and cathode materials, separator technology, and emerging electrolyte-impregnated polymers.

State-of-the-art batteries

Whether it is quick prototype resin printing, multi-photon polymerization or a custom CNC machined component, we are ready to bring new ideas to life. With the aid of advanced software such as Solidworks 2010 and Comsol Multiphysics we are able to virtually build prototypes and even test them in the computer before ever producing a physical part, saving both time, resources and money.

We are currently working to improve li-ion technology by renovating all components of a battery by testing the use of more exotic materials such as advanced ion conductive polymers, carbon nanotubes (CNTs), nitinol, solgels and aerogels to improve on the current state-of-the-art methods. We are also testing the effects of reducing particle size of established materials into nano size particles. This enhances not only the overall surface area and capacity, but some materials even show exciting properties unique to the sub-micron level.

Environmentally friendly rechargable batteries

Maximizing efficiency in rechargeable batteries is a must as the world looks to new, cleaner and planet-friendly power sources. With traditional rechargeable batteries energy is lost in the charging process as heat, which must be kept to a minimum to prevent meltdown and fire hazards.

The traditional solution is to slowly charge a battery either with small amounts of current or by cycling the charging state on and off giving things a chance to cool. Our solution is to reduce the resistance of ion flow between anode and cathode and use new materials and methods that are more resistant to heat while being more receptive to the energy exchange.

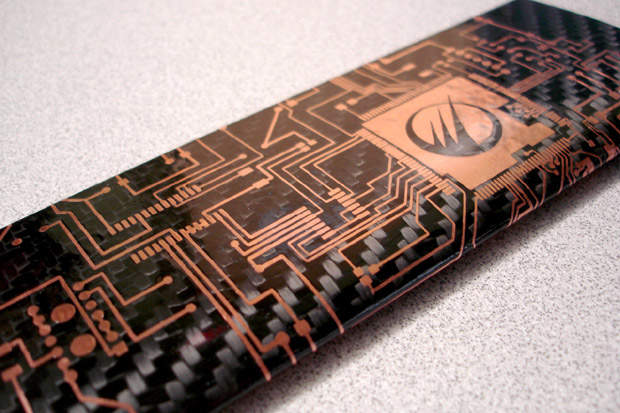

Flexible lithium polymer battery

Our goal remains making batteries more powerful by weight and size. However, we also keep an important focus on batteries that are moulded and/ or shaped to fit specific, non traditional, shapes and areas so that the device does not have to be built to accommodate the battery.

Flexible lithium ion polymer technology also enables batteries to wrap around objects and follow contours without risk of shorting out. Smaller, faster, lighter is one of the most prevalent trends in mobile and handheld device development. Our drive is to continue to make smaller more reliable batteries and power sources that can recharge faster with fewer thermal issues while maintaining greater storage capacity and stability.

Nanobattery for the power industry

With no comparable products currently on the market, US Photonics’ ENDURE nanobattery stands alone in its ability to provide a multi-function nanobattery with the endurance, flexibility, reliability and adaptability to change the way the world uses power in the workplace, in the home, on the road, and on the battlefield.

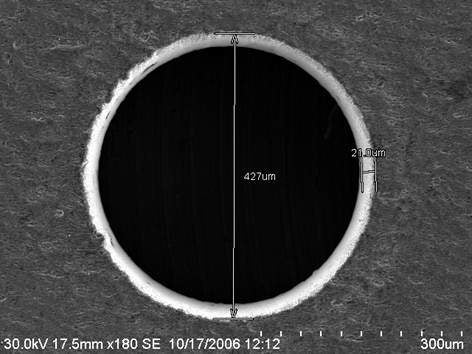

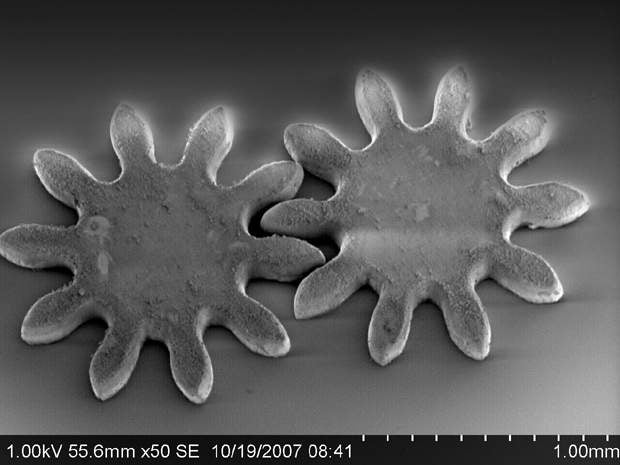

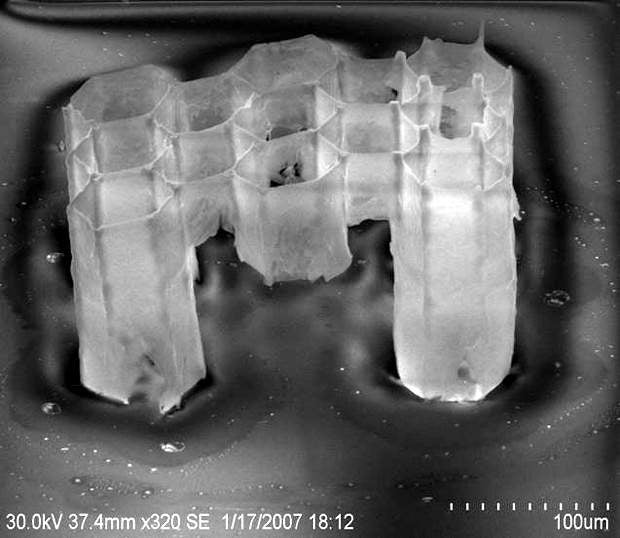

With a cell that is only nanometers in dimension, the ENDURE nanobattery can be configured and connected to scale the output of power by accessing groups of cells into different size banks allowing for a variable output that transcends all boundaries and spans all applications. Additionally, with its extremely high surface-to-volume ratio, it provides a virtually instantaneous recharge. Fabricated on flexible polymer jackets, the nanobattery is not only small, but also practically weightless and heat resistant. Through the isolation of each cell, the ENDURE nanobattery also ensures continued reliability; if a large number of cells become damaged, the system remains intact preventing a complete loss of power.

Femtosecond laser machining, coupled with the use of techniques perfected by US Photonics, also provides the ability to rapidly adapt and customise the technology to meet changing customer requirements.

Finally, US Photonics stands firm in its commitment to produce energy sources that are environmentally safe. By using far fewer amounts of corrosive metals and acids per unit of energy delivered, the ENDURE nanobattery allows for safer use and disposal.