Surviving the summer heat is a breeze for consumers these days with the luxuries of air conditioning and refrigeration, but for power stations in many parts of the world, summer signals a danger zone of unpredictable demand peaks that threaten to send supplies into the red. It's not just the hot weather that can sap the life out of supply – the impact of drought, heating use in cold winters and political instability all impact on the ability to meet consumer-led

peaks.

On the historic hot day of 18 July 2006, National Grid in the UK had to pay 45 pence per kilowatt hour for emergency output – three times the amount the average household pays for electricity. Even when an alternative source of power is available, such as wind or solar, challenges can arise. Insufficient sunlight or wind speed can also bring about potential shortfalls.

Historically, ramping up the power output when the grid needs it is how power systems have been developed, but with increasing environmental concerns and stringent attention on the financial aspect, people are taking more innovative looks at how to overcome these problems. More responsibility is now placed on power stations to integrate technologies that can help them respond to peak demands in more efficient, environmentally friendly and cost-effective ways.

THE POWER EQUATION

When the supply/demand equation becomes unbalanced, it's up to the grid to then notify the market that demand must be adjusted. Industrial users reduce power needs, and prices for electricity are raised to encourage residential consumers to pull back.

Less reactive efforts to reduce consumer demand include home technologies that encourage consumers to use electrical appliances at off-peak times, such as 'smart' appliances that deny use in peak periods, or 'intelligence' switches that turn off appliances when not in use.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataIn Los Angeles, the 'Flex Your Power' scheme – where consumers are offered financial incentives to use appliances at off-peak times – is central to balancing supply and demand. In the UK, the 2007 Energy White Paper projected that residents will have a 'smart meter' within ten years in order to decrease demand during peak periods.

While grid companies are usually able to forecast high-demand periods, there are times when peaks catch them by surprise, which can result in blackouts, grid overloads and industrial power outages.

In California, a summer heatwave at one point left 29,000 homes without power due to the combination of excessive air conditioner use and equipment failures at power stations.

Power cuts also threatened Italy in summer 2006 because of a lack of water to cool power stations, and in Australia the summer combined with low water supplies is predicted to severely decrease reserve margins.

Even in the UK, where the peak demand period usually falls in winter, high electricity demands during the swelteringly hot summer of July 2006 contributed to power cuts in London by the capital's energy company EDF, resulting in 760 customers without power and

the temporary closure of Oxford Circus tube station.

It is therefore easy to see that solutions to the supply-demand strain are not just a matter of increasing power output and cutting down demand.

WITH INNOVATION, CAN RENEWABLES HELP?

The global shift to increasing green energy use means that renewables are being relied upon more and more to provide emergency supplies, but often their supplies are unable to coincide with demand.

One way of overcoming the two-tiered challenge of providing cost-effective energy output when and where the grid needs it, and also overcoming intermittency of renewables sources, is by using energy storage systems.

The First Hydro pumped storage plant in Dinorwig, North Wales has been called on by National Grid in times of peak demand in the UK since 1984. Such systems are very energy and cost efficient, and are perfect for getting power onto the grid fast (the First Hydro plant can go from 0–1,730MW in under 90s). However, pumped storage systems can only function in areas with particular geographic characteristics.

They work by pumping water from a lower reservoir to an upper basin at low peak times, then during the high peak the water at top is released down through a high-pressure shaft which then drives the turbines to generate electricity. Two reservoirs at different altitudes are required for their operation.

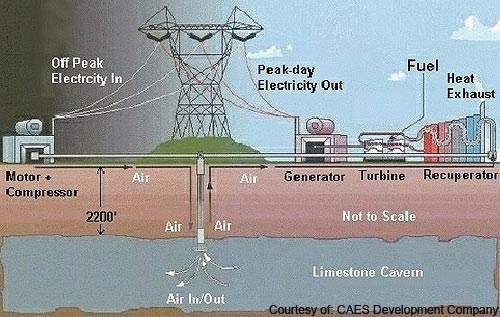

Another storage system receiving growing interest, especially in the US, is Compressed Air Energy Storage (CAES), whereby off-peak power is used to compress air in underground caverns.

When demand is high, the compressed, high-pressure air is released to drive turbines that then generate electricity.

CAES schemes may be built to support existing power stations. Currently there are only two in the world – a 290MW plant in Germany and a 110MW plant in the US.

"CAES systems can be very effective both financially and in terms of carbon mitigation; and they have the potential to yield significant cost savings," says John Baker, principal consultant at power technology consultancy EA Technology.

CAES systems can also store large quantities of energy (50–300MW) for long periods of time (multiple hours, to days/weeks), and have a start-up time of about nine minutes – perfect for emergency production. However, like pumped storage systems, the existence of CAES systems is reliant on unique geological formations.

Other energy storage technologies gaining much interest in the UK are batteries and flow batteries. "Lead acid is the granddaddy of batteries," says Baker, "and is still a contender [for electrochemical storage solutions], but there are also a series of more advanced batteries in the pipeline including sodium sulphur, sodium nickel chloride and lithium ion battery systems. The sodium sulphur system, in particular, is being heavily promoted by the Japanese company NGK.

"There is certainly interest in electrochemical storage in the UK, but I'm not aware of any substantial deployment. There are variations on batteries called flow cells, and there is very significant interest about these in the UK, and significant developmental activity."

FROM THE NON-RENEWABLES SECTOR

Michael Simmangk, director of strategy and marketing for the Plants Business of Alstom, a global leader in equipment and services for power generation, has a different solution. He says building plants with high load flexibility as well as the latest in turbine technologies enables plants to fire up and meet peak demands at optimal functional level.

Alstom's Gas Plant KA26 is one example. It operates with high load flexibility at part load and even at low-load level of 15% power output while still meeting demands of efficiency and lowered carbon emissions, as well as harbouring a spinning reserve.

"If the station is parked on this low load it's very easy to ramp it up," he says. "This ensures they are going to be fast onto the grid to meet peak demands, and increase stability of the grid."

"What we're pushing is the integration of the various features at the overall plant level to make the plant flexible and capable of increasing the power in a very short time."

Other power augmentation technologies included in Alstom's integrated plant enable the power station to add additional power output if and when it is needed. These include air inlet cooling, where fog is inserted into the air inlet of the gas turbine; and supplementary firing – where additional firing can be installed behind the gas turbine in the heat recovery steam generator.

"You can then switch this on and it will boost power output," says Simmangk. "This can be switched on and off as needed."

Creating this enhanced cycling behaviour and the overall ability to park the plant is the sequential combustion turbine GT26, which has the ability to shut off one of the combustors and park the whole plant at low-load. "This has an impact on the overall plant operation," Simmangk adds. "Imagine the turbine is working on a very low load – all the other components need to be adjusted to work on this level of low load operation."

Integrating high load flexibility, high-efficiency plant technologies combined with power augmentation is an ideal contribution a power station can make to addressing supply issues when seasonal demand peaks occur. But while these technologies can play a part in meeting or reducing peak demands, that age-old obstacle of implementation costs will see the key contributing solutions remaining on the consumer-end of the market.