Robotic solutions have advanced rapidly over the past decade, becoming an essential technology in the inspection and management of wind turbines. Since the first drone inspection was conducted in 2010, robotics has evolved to become a $14.21bn market within the energy sector, projected to reach $36.89bn by the end of 2030.

Now, drones take thousands of photos, while crawlers access hard-to-reach places and integrated AI solutions analyse vast quantities of data at speed.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Their proficiency offers a solution to a gaping skill gap. Rope-access technicians can be substituted for winched crawlers, and drones are able to take thousands more images than manned aircrafts.

However, as robots reshape the wind turbine maintenance sector, the need for human supervision has – for now – persisted. The industry drive to provide value to customers has resulted in a collaborative approach in which robots are considered colleagues rather than replacements, and the question of eventual complete automation is one that remains unanswered.

Surmounting the size problem

Wind turbine inspection and repair can be a minefield, riddled with practical headaches and logistical complexities.

One obvious challenge is the mammoth size of wind turbines: turbines vary in height, but the US Government reported an average hub height (from base to nacelle) for land-based turbines of 103.4m in 2023 – taller than the Statue of Liberty.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThe difficulty posed by working at extreme height is compounded by the challenge of operating in offshore locations, where turbines are often taller. The Australian Government reported in March 2025 that its newest offshore wind turbines were 260m in (hub) height and would be placed in the Bass Strait region, at least 30km offshore. Remote locations offer the advantages of strong winds and easier public approval, but harsh environmental conditions exacerbate already-challenging inspection and repair tasks.

Specialists in the inspection of critical infrastructure, Zeitview uses visual AI and robotic solutions to address maintenance challenges. Chief technical officer Matt Falk explains how the company uses drones for difficult-to-reach external inspections: “Drones are a lot more flexible. We can get close and work around the curvature of the particular asset that we are looking at, using semi-autonomous drones to capture imagery and get the data we need.”

Drones remain a central part of the offering for Zeitview, previously named DroneBase, but it has expanded to encompass other technologies. These include crawler robotics, an example that Falk points to as a solution to the size problem.

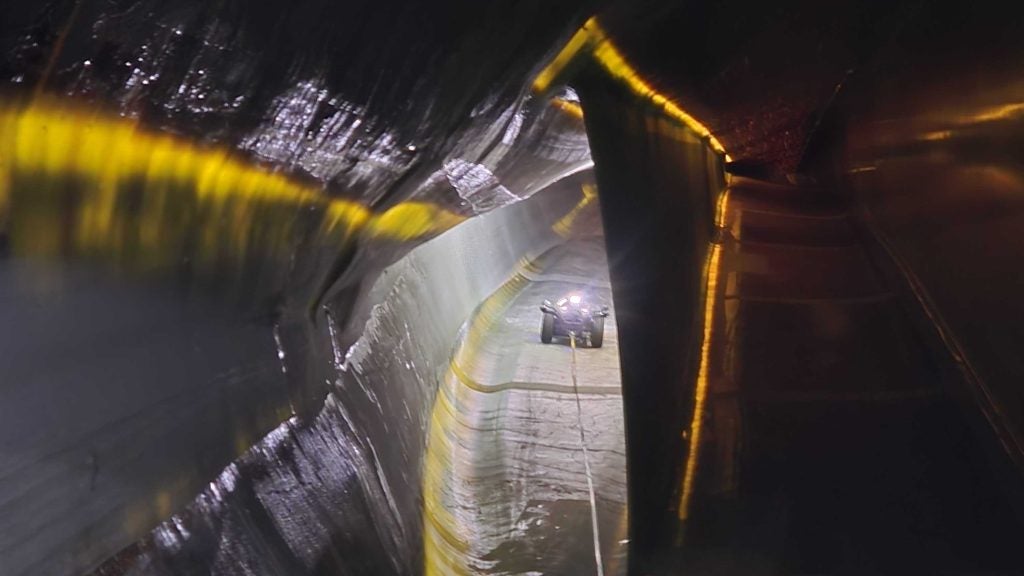

“In certain cases, we want to go inside an asset. The most common request currently is for wind turbine blades. We go inside the blade itself, get imagery and collect data,” he explains.

The blades of onshore wind turbines tend to average around 50m in length, while offshore turbines tend to be larger, averaging 79–88m. The width (known as ‘chord’) inside a blade is usually around 3m. This makes for a long, dangerous and dark journey for human engineers, but crawler robots, says Falk, can complete the job with ease.

“Crawlers offer fine control,” he says. “Drones can’t fly that deep into the blade, so you miss out on a lot of data unless you use a crawler or another remote-control vehicle on the ground. A ground vehicle can go further into the blade than a drone can, obtaining more imagery. Additionally, because crawlers don’t use a propeller system, they don’t blow dust around the blade, which hurts the images that you are taking.”

Consistent and efficient: sometimes robots are just better

Dainis Kruze, CEO of Aerones, a robotic solutions provider for wind turbine inspection and maintenance, explains that “robotic systems perform the physically demanding and dangerous work – capturing inspection data, conducting repairs and cleaning blades at height – while human operators and specialists remain safely on the ground”.

“The result is safer, faster and more efficient wind turbine maintenance compared to traditional rope-access methods.”

However, safety isn’t the only concern. Human technicians mean human error, and robots can offer a level of consistency that is impossible for human wind turbine technicians to achieve.

“Repair operations demanding high precision and uniform material application can be automated to exceed human capabilities, ensuring consistent quality across all repairs,” explains Kruze.

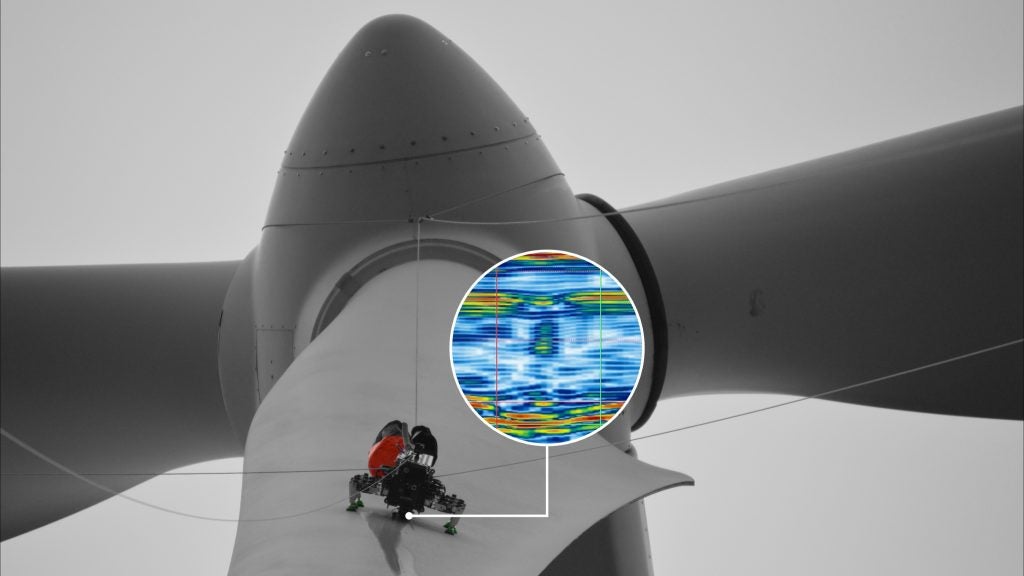

Most wind turbine operators rely on ultrasonic scanning as a non-destructive testing (NDT) method to identify delamination, cracking and blade erosion. Ultrasonic pulses are emitted into the blade and travel through the composite material, reflecting or scattering when they encounter an inconsistency. Analysis of the path of these high-frequency sound waves can detect anomalies, which indicate structural issues.

Ultrasonic scanning is crucial but requires a human with both NDT expertise and rope access training to perform the task at height. Even then, there is room for error if technicians fail to scan part of the blade, scan one area twice or move in the wrong direction.

Robotics can solve this issue. James Concannon, operations and business development manager at robotic ultrasonic NDT provider BladeBUG, stresses the accuracy robots can deliver compared to their human counterparts.

“In up-tower ultrasonic inspection, you might use a different rope team and NDT team each time. Two different technicians will scan the blade in their own slightly different method, but customers want a data set that is uniform and retrieved in the same way,” Concannon explains. “By using a robot, everything is automated and measured with encoders, so you can track distances exactly and guarantee you are getting the same scan path every time. You will therefore get the same data structure and data quality.

“It removes the room for human error.”

Robots help bridge skills shortages

Even as robotic solutions progress, qualified rope access technicians, with the expertise to scale towers and work at height, are in high demand; a predicted 569,000 wind technicians will be needed globally by 2026 to support turbine operations.

As the demand for qualified technicians outstrips supply, the energy transition depends on finding solutions to the skill gap. Concannon points to robotics as a potential answer: “With our system, you don’t need an expert on site… we can stream the data to a remote NDT expert who can analyse the data from anywhere in the world. Robots are reducing the number of high-skilled experts needed on site, and it is a major advantage.”

Inspection is one side of maintenance, but repair is its more complex cousin. Currently, most robots are not yet capable of carrying out wind turbine repairs, and although this will change as the sector continues to develop, there is still a demand for humans qualified to carry out work flagged by inspection robots.

“A lot of maintenance needs are nuanced, and we still rely heavily on humans to perform that type of repair or remediation. The tasks are much more unconstrained and require an understanding of the root cause for a true fix, and I don’t think robotics is fully quite there yet,” explains Falk.

The Netherlands Organisation for Applied Scientific Research (TNO) is researching opportunities to change this trajectory, hoping to introduce repair robots to wind turbine management in the future. “Most robotic solutions in the wind industry are aimed at inspection activities, but things are slowly picking up for repair,” says Janaki Mohanan Nair, project manager for wind energy at TNO.

“There are leading-edge erosion repair robots appearing on the market now, which work on the blade exterior. We have also developed a prototype of a robot that can install sensors inside the blade. The inside of the blade is a confined space, which presents safety issues for humans, but robots could perform inspection as well as maintenance work safely.”

TNO is supporting the development of robotic technology in conjunction with other cutting-edge developments for wind operations. Noting the example of the company’s augmented reality glasses, Jan Willem Wagenaar, programme manager for wind energy at TNO, says that extended reality (XR) and virtual reality (VR) also offer solutions to the issue of skills scarcity. “If the expert is onshore, XR and VR can assist various human colleagues in conducting tasks more easily and make the best use of their capabilities,” he notes.

AI in robotics: intelligent robots can support human innovation

The automation of repetitive tasks enables experts to dedicate more time elsewhere, developing high-value solutions for customers. AI is already integrated into many of the robotic solutions available in the wind turbine management sector and, according to Falk, represents an opportunity for human innovation.

“As AI learns to look for cracks, humans can look for erosion. When AI learns from that, humans can look for other anomalies. Each time AI fills a gap, humans can go and look for the next thing. It provides an opportunity to continuously provide more value for customers while keeping both humans and robots in the process.”

AI can trawl through vast quantities of data and locate discrepancies at a rapid pace and, when paired with robotics, the coupling constitutes an intelligent, automated colleague that enables human productivity.

Companies across the robotics and energy asset maintenance sector are employing AI to provide this value to customers. The market is growing, with Grand View Research projecting that the global AI in robotics market will reach $124.77bn by 2030, with a predicted compound annual growth rate of 38.5% between 2024 and 2030.

Despite this forecast, Concannon states: “I don’t think it is ever going to get to a point where there is zero human interaction. I think it can get pretty damn close, but we will still need the human element.”

The idea is not for robots and AI to replace human input, but to reshape it.

“Customers are increasingly viewing AI and robotics as tools that augment rather than replace human capabilities. They are looking for solutions that reduce costs and improve safety while maintaining the reliability and accountability that come with human oversight,” Kruze concludes.

Frequently asked questions

-

How long will a wind turbine last?

Wind turbines have a lifespan of between 20 and 25 years, depending on the level of maintenance provided and the conditions the wind turbine is placed in. Erosion happens faster on coastal sites, which experience strong winds and salty air. Leading-edge erosion on blades means that repairs are typically needed every two to five years, and cracks and structural issues often appear between 10 and 15 years.

-

What is NDT?

NDT stands for non-destructive testing and refers to various techniques used to assess the strength, quality and integrity of materials without causing any damage. It is used across a range of sectors, including healthcare, construction and aerospace, as well as to assess energy assets, such as wind turbines. Common methods include ultrasonic testing, radiographic testing, magnetic particle inspection, and dye penetrant testing.

-

How does ultrasonic testing work?

Ultrasonic testing is based on the principle of sonar and involves using a transducer to transmit sound signals through a material. The returning echoes are received by the original or a secondary transducer and analysed to assess the location, size and depth of any irregularities. Ultrasonic testing is useful in predictive maintenance, because issues can be picked up and addressed before they become significant.

-

How often do wind turbines need to be inspected?

Wind turbines usually need to be inspected around twice a year, however routine maintenance may be more frequent. Timescales can vary, depending on the size, location and model of the turbine, but manufacturers usually provide recommended inspection schedules. Typically, offshore turbines require more frequent inspection, as exposure to saltwater can cause corrosion, and high winds can erode blades. Once every one to two years, wind turbines are cleaned, to remove debris and pollutants that reduce efficiency.

-

What are the most common maintenance issues for wind turbines?

Leading edge erosion is the most common maintenance issue for wind turbines, caused by exposure to rough extreme weather conditions, which weaken the blade’s surface. Material fatigue, impact damage, and environmental exposure are also common issues which cause cracks and delamination in wind turbine blades. Gearbox and bearing failures are also common, caused by the general wear and tear of high-speed rotation, while gear failures are often caused by degraded lubrication.