Siemens has been contracted by Braskem to upgrade cogeneration power and steam plant at a petrochemical complex in Sao Paulo, Brazil.

Siemens will deploy, operate and maintain the existing plant for 15 years.

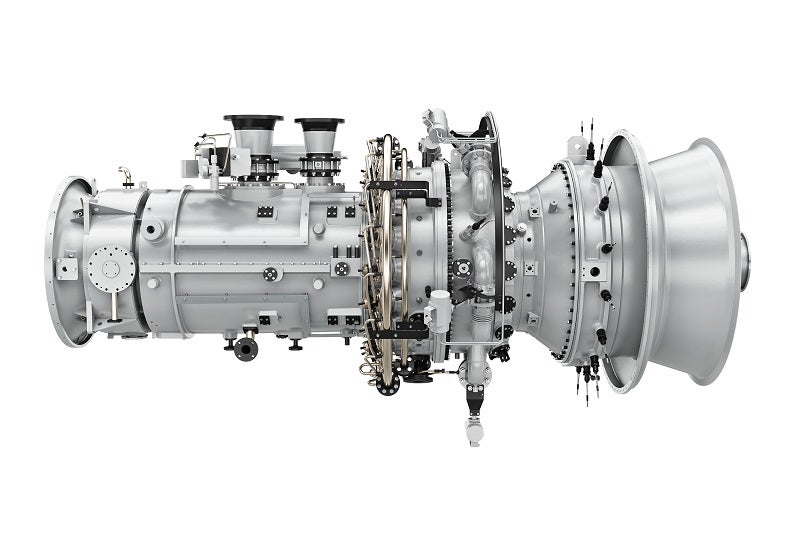

Siemens will implement a fully integrated equipment solution that includes two SGT-600 gas turbines and an E-house.

The gas turbine is designed to provide 19MW of power and 80t per hour of steam. It features third-generation dry low emissions (DLE) technology that lowers CO2 emissions and NOx levels from the turbines. The turbines operate on residue gas with high concentrations of hydrogen.

In addition, the company will be responsible for an extension of the existing high-voltage substation, deployment of three reciprocating compressors, an advanced load-shedding system, and related software for plant control. The project is expected to complete by early 2021.

Siemens Gas and Power head Dan Simpson said: “Siemens was uniquely capable of proposing this comprehensive engineering and service solution that will help Braskem meet its sustainability goals and maximise value over the life of the cogeneration plant.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalData“The integrated and redundant design of the facility and use of Siemens equipment, coupled with the adoption of a build, own, and operate business model will result in 100% plant availability and reduced energy consumption, both of which are critical to Braskem’s business.”

Braskem’s cogeneration plant supplies steam and power to the petrochemical complex’s cracking unit that produces 700,000mt of ethylene a year.

Braskem Chemicals southeast region chief industrial officer LuísPazin said: “The combined cogeneration of electricity and gas with this project exemplifies our efforts to achieve greater operational excellence and reinforces our commitment to sustainable development.

“The modernisation will help us meet our sustainability goals by reducing the facility’s overall energy consumption by an amount equivalent to that of a city with one million inhabitants.”