Aggregate Burner Drying Equipment

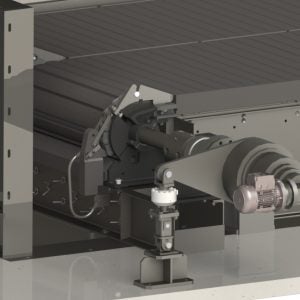

Detroit® HADES Burner – High-Efficiency Burner for Aggregate Drying

The Detroit® HADES Burner is a sealed-in burner developed for hot aggregate drying applications. Designed with durability and efficiency in mind, it features a compact footprint, energy-saving low horsepower fan motors, and variable frequency drive (VFD) operation for even greater savings. The HADES Burner incorporates primary flame stabilization and secondary flame shaping to support wide turndown ranges, rapid production changes, and maximum dryer efficiency. With low NOx levels, ultra-low CO emissions, and simplified maintenance requirements, the system offers a low cost of ownership. It supports natural gas, propane, No. 2 oil, and heavy or waste oils with compressed air atomization and is backed by Detroit Stoker’s engineering and service team.

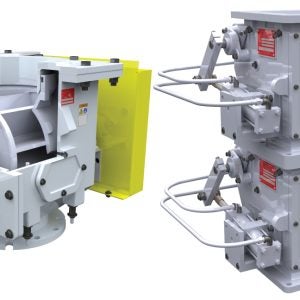

Detroit® HADES Burner Control (HBC) – Smart Panel for Dryer Efficiency

The Detroit® HADES Burner Control (HBC) panel offers advanced control and monitoring for the HADES Burner system. Its characterized air/fuel ratio control maximizes fuel efficiency, while built-in features like ‘first-out’ annunciation and hot-stop functionality reduce downtime and support rapid restarts. The system allows seamless switching between fuel oils and includes intuitive HMI displays for operational clarity. It supports flue gas recirculation, integrated draft control, and baghouse temperature alarms. With options for manual or automatic operation and built-in data logging, the HBC panel is engineered for production efficiency, flexible fuel use, and long-term system reliability—all within a compact, standardized enclosure.

To learn more, please download our product brochures here.