Stern Laboratories has extensive experience performing heat transfer experiments to determine critical power for pressurised heavy water reactors (CANDU), pressurised water reactors (PWR) and boiling water reactors (BWR) for many customers.

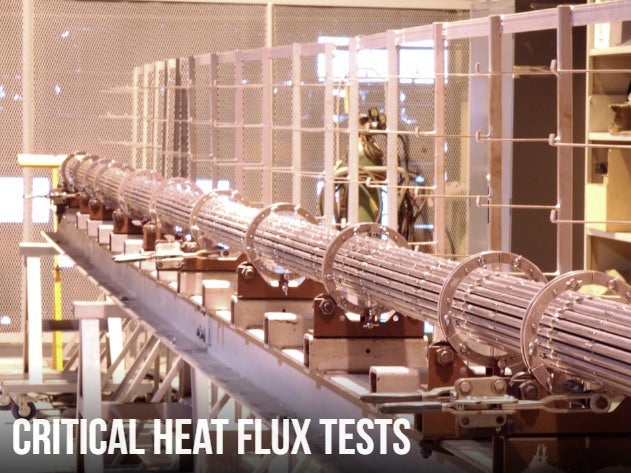

Critical Heat Flux (CHF) tests have been successfully performed in full scale, horizontal CANDU fuel channels at reactor operating conditions using directly heated fuel simulations representing 28-element, 37-element and 43-element CANDU fuel. The fuel simulations typically have segmented geometry (end plates) and non-uniform axial and radial power distributions.

The fuel simulations are equipped with movable internal thermocouples which can be remotely positioned to monitor critical power (dryout) over most of the surfaces of the downstream bundle elements. Experiments have been performed using flow channels simulating both uncrept and crept pressure tubes.

Boiling Transition (BT) tests have been successfully performed in full-scale vertical BWR fuel channels (up to 10×10 bundle arrays) at reactor operating conditions using indirectly heated fuel simulators equipped with internal thermocouples (up to 12 per rod) at precise locations to determine critical power.

The fuel simulators can have various axial power distributions (cosine, inlet peaked, outlet peaked, uniform, etc) and can be powered individually to provide multiple radial peaking patterns. The use of indirectly heated fuel simulators allows reactor grade spacers to be employed, as well as the fuel simulations to be arranged to minimize magnetic forces during testing.

Departure from Nucleate Boiling (DNB) tests have been successfully performed in vertical PWR channels (up to 5×5 bundle arrays) at reactor operating conditions using indirectly heated fuel simulators equipped with internal thermocouples (up to 12 per rod) at precise locations to determine critical power.

The fuel simulations can have various axial power distributions (uniform, symmetrical cosine, inlet peaked, outlet peaked) and can be powered individually to provide variable peaking patterns. The use of indirectly heated fuel simulators allows prototypical reactor spacers to be used, as well as the fuel simulations to be arranged to minimize the magnetic forces during testing.

The power supply has up to 16MW of 12-pulse rectified DC power available with 13 controlled power zones which operate individually at up to 330V to neutral or in pairs at up to 660V differential (+330V to -330V). The power supplies can be operated in parallel for directly heated fuel simulations or independently for indirectly heated fuel simulators. The power supplies have accurate power metering and are computer controlled to provide preset distributions and programmed power ramps.

For BWR and PWR tests with indirectly heated fuel simulators, multiple zones can be controlled on-line to provide unlimited radial peaking patterns. The power supplies are typically connected with the current flowing in the reverse direction for approximately half of the rods to minimise magnetic forces.

A modern data acquisition system monitors and records the test conditions and provides critical power detection for all of the fuel simulator thermocouples at scanning rates of typically 10Hz per channel.