Services

Detroit® Service & Support – Maintenance, Upgrades, and Grate System Expertise

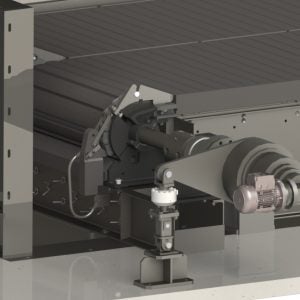

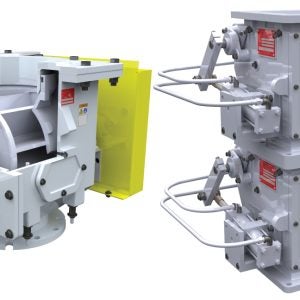

Detroit Stoker Company provides comprehensive service and support for solid fuel combustion systems, specializing in the maintenance, inspection, and upgrade of stokers/grates, fuel handling, and ash systems. With over 125 years of combustion experience, our global support organization is trusted by operators worldwide to deliver expert engineering, site supervision, labor, and dependable Detroit® equipment and parts. Whether performing routine preventative maintenance, conducting system tune-ups, or executing complex retrofits, our service team helps ensure maximum plant availability, optimal performance, and extended equipment life.

We support not only Detroit® equipment but also combustion systems from other major manufacturers. Our services include full system inspections, combustion tuning, flue gas testing, and operational adjustments to improve efficiency and emissions control. While our primary focus is on grate-fired and solid fuel systems, we also offer burner conversion solutions—retrofitting existing equipment with Detroit® DB low NOx burner systems and turnkey burner installations for auxiliary or low-load applications. From field repairs to full-scale upgrades, Detroit Stoker Company is your partner in combustion system reliability.

Computational Fluid Dynamics (CFD) Modeling – Optimize Combustion and Emissions

Detroit Stoker Company uses Computational Fluid Dynamics (CFD) modeling as part of its engineering process design to enhance combustion system performance and reduce emissions. CFD modeling allows Detroit Stoker engineers to estimate flue gas properties within a unit and evaluate the design and operation of primary and secondary air systems. A computer model of the client’s furnace is developed to establish baseline temperature, flow behavior, and flue gas conditions. Simulations are then run to test new overfire or secondary air injection strategies, with system configurations adjusted to optimize performance. Results are compared against baseline data to identify improvements. Clients provide boiler dimensions, operational data, and energy inputs/outputs to support this evaluation process.

To learn more, please download our product brochures here.