A water treatment system which harnesses the natural properties of the water to solve scale, corrosion and biolife problems by applying a designated chemical reactor to react the excess of minerals naturally present in the water.

Process description:

Water is passed through a series of reaction chamber. By applying DC voltage to electrodes in the chambers OH- ions are produced by partial electrolysis of the water. The addition of OH- ions promotes scale formation with the excess of ions Ca+2 and CO3-2 (Ca+2 + 2 CO3-2 + OH- = CaCO3 + CO2 + H2O) in the chambers. Biocide is released as well as part of an IN-SITU process for electro-chlorination. This will eliminate bacteria and viruses in the system.

Through this unique electrochemical process, UET’s dynamic equilibrium shift is accomplished in the reaction chamber resulting in deposit free heat exchangers surfaces. Shifting of the pole position during the purge cycle sends concentrated water to the drain. During the purge cycle, a small amount of water, highly concentrated with minerals, is discharged; minimising water loss to bleed and allowing increased cycles of concentration.

Features:

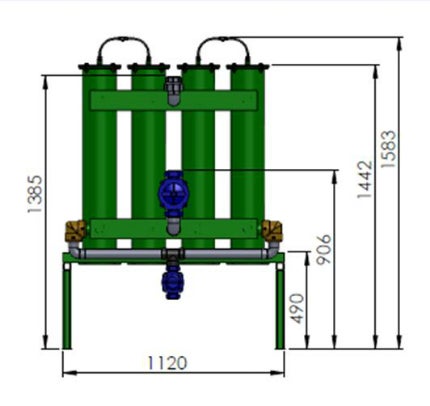

- Factory pre-wired and pre-plumbed system

- Automatic flushing control

- Reliable diaphragm operated valves

- Controller indicating actual current

- Automatic controller adjusting amperage

- One-year warranty

Advantages:

- Physically removes scale inside the reactors

- Scale, Corrosion and biolife control – all in one unit

- Easily-installed and serviced

- Safe environmental friendly scale control

- Proved to save substantial amounts of water by allowing to raise cycles of concentration

- Reduces chemicals consumption

- Reduces operational and maintenance costs

- Local service and parts decrease down-time