The 1.1GW Allen Combined-Cycle Plant is a natural gas-fired power plant located approximately 8km from Memphis in Tennessee, US.

Developed by the state-owned power utility Tennessee Valley Authority (TVA), the plant replaced the 55-year-old Allen Fossil Plant, which was decommissioned in 2018.

Construction of the two-in-one combined-cycle plant began in November 2015. The plant became operational in April 2018. The facility produces enough electricity to power more than 500,000 average US homes.

The project also included the construction of a 1MW solar farm and 5MW renewable biogas facility, which generates an additional 5MW of power.

The development required an estimated investment of $975m.

Allen Fossil Plant and its replacement details

The 500-acre Allen Fossil Plant is located near McKellar Lake, Memphis. It features three coal-fired units with a combined capacity of 741MW.

Memphis Light Gas and Water (MLGW) constructed the plant between 1956 and 1959. TVA initially operated the plant on lease from 1964. The company purchased the plant in 1984.

The plant currently provides electricity for the Memphis area as well as a larger part of the western region.

The new combined-cycle plant will continue to provide electricity for the regions covered by TVA.

Allen’s three coal-fired units stopped operations in line with the US Environmental Protection Agency’s (EPA) December 2018 deadline for the reduction of coal emissions.

The new facility is a third replacement combined-cycle plant built by TVA to comply with the new air pollution regulations.

Combined-cycle power plant details

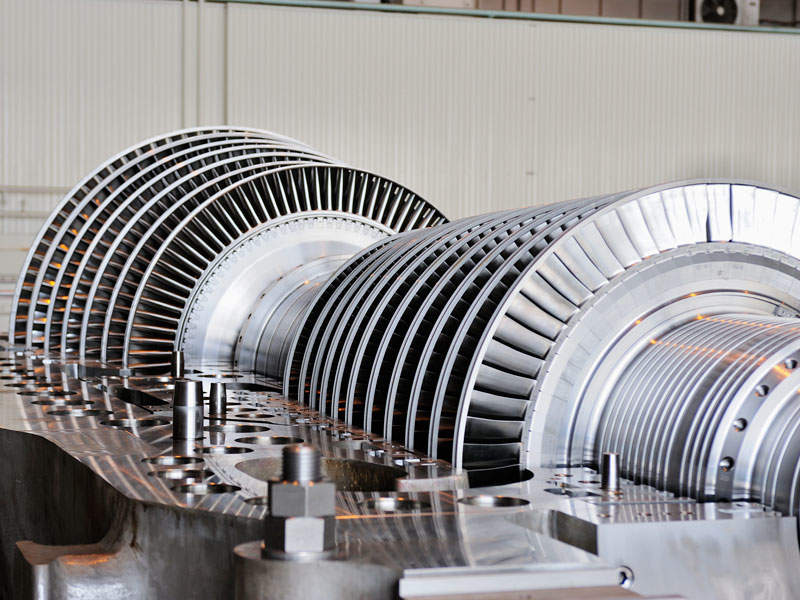

The new plant uses TVA’s state-of-the-art technology and is equipped with GE’s latest 7HA.02 combustion turbine technology, which uses one of the world’s biggest and most efficient 60Hz gas turbines.

7HA technology offers a net combined-cycle efficiency of more than 61%. The turbines are supplied in GE’s prime packaging, which is a modular packaging configuration that reduces installation time.

The Allen plant’s simulator features the latest ProTRAX 7.4 modelling system, two GE 7HA.02 gas turbines, two heat recovery steam generators (HRSG), a Toshiba steam turbine generator and related controls.

The simulator is equipped with virtual Emerson Ovation, virtual GE MarkVIe and translated Toshiba controls. It supports equipment testing before installation, which enabled early plant commissioning.

The 1MW solar facility produced first power in August 2017. It is the TVA’s biggest solar project with more than 3,000 solar panels in its service area.

TVA partnered with the City of Memphis to capture methane gas from the TE Maxson Wastewater Treatment Plant, which is located adjacent to the new combined-cycle gas turbine (CCGT) plant site.

The methane gas is cleaned, dried and transported to the CCGT plant, where it is burned in an auxiliary boiler to produce steam.

The steam powers the turbine, generating enough electricity for 3,000 homes.

Natural gas and water supply for the Allen CCGT power plant

MLGW is responsible for transferring natural gas for the new combined-cycle plant via a new pipeline. It was built within an existing right-of-way along the MLGW gas pipeline corridor.

The plant requires between seven and ten million gallons of water a day for condenser cooling.

In addition to the installation of groundwater wells, TVA buys water from MLGW and uses it to meet any additional water requirements during peak times.

Power generation at Allen plant

The operational procedure of the two combustion turbines at the Allen Combined-Cycle Plant can be compared to that of jet engines.

The GE turbines draw air, compress and mix it with fuel and, finally, ignite. Each turbine is connected to a generator.

Hot combustion gases are captured from the turbines, combined and used to generate steam to drive a single-steam turbine, which produces an additional 50% output compared to the combustion turbines alone.

During the process, a catalytic converter removes carbon monoxide, while a selective catalytic reduction (SCR) system eliminates nitrogen oxides.

Transmission

TVA constructed two new 161kV transmission lines for the power plant. The company also uses the existing 161kV switchyard.

Operated by TVA, the new transmission lines are located between the existing switchyard and new combined-cycle facility to connect to MLGW’s regional transmission system.

Contractors involved

Kiewit Power Constructors provided the engineering, procurement and construction (EPC) services for the plant development.

The company subcontracted Campbell & Ford Construction to build administrative and water treatment facilities for the project and B&W Energy Services for pre-commissioning services. Vogt Power International supplied heat recovery steam generators (HRSGs).

GE is the supplier of two 7HA.02 gas turbine generators for the Allen Combined-Cycle Plant. Toshiba supplied a 472MW steam turbine and generator (STG). TVA contracted TAX for providing the simulation system for the plant.

Other contractors include Allworld Project Management, VuCon and Bluewater Industrial Cleaning Services.